Load mechanism for aircraft anti-G tester

A technology of loading mechanism and tester, applied in the direction of aircraft component testing, etc., can solve the problems of inability to load weights, hidden dangers of product quality, high labor intensity, etc., to verify the normality of work, improve the efficiency of test work, and ensure flight. safe effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The principles and features of the present invention will be described below in conjunction with the accompanying drawings.

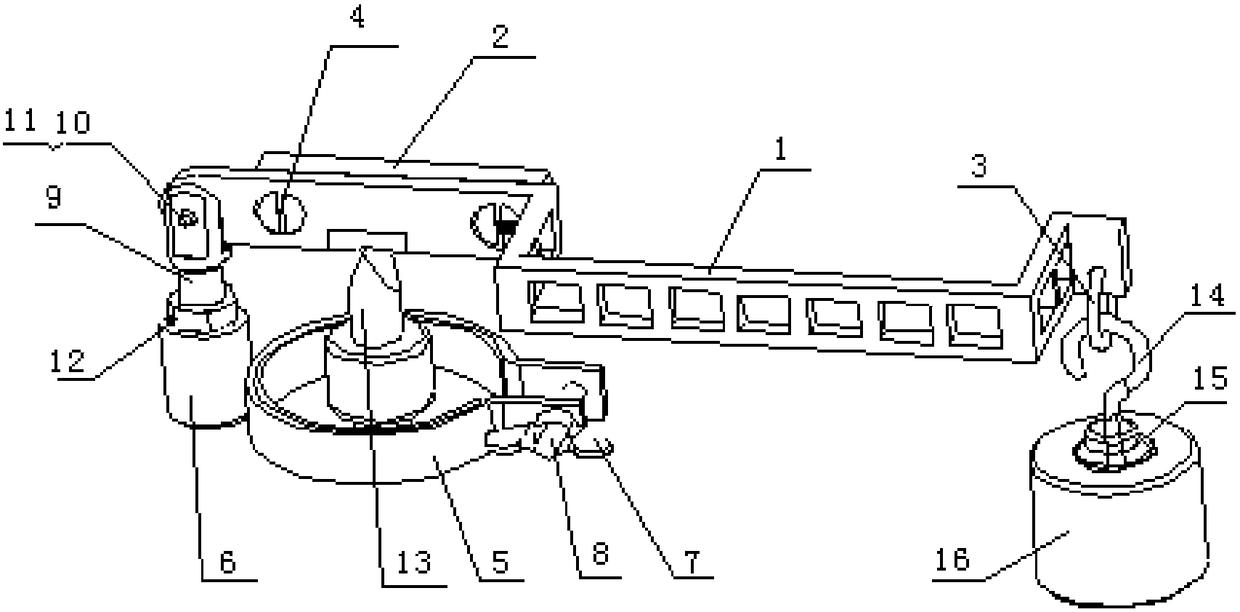

[0012] A loading mechanism for an aircraft anti-load tester, comprising a rod body 1, a counterweight 2, a ring 3, a screw 4, a collar 5, a round nut 6, a strut 9, a bearing 10, a shaft pin 11, a nut 12, a top Rod 13, hook 14 and weight body 16, the counterweight 2 is fixed on the rear of the rod body 1 by screws 4, the strut 9 is installed on the tail of the rod body 1 through the bearing 10 and the shaft pin 11, and the round nut 6 passes through the nut 12 is connected with the strut 9, the collar 5 is welded with the round nut 6, the open end of the collar 5 is provided with a wing nut 7 and a screw 8, and the upper tip of the ejector rod 13 rests on the bottom of the rear groove of the rod body 1 Placed on the anti-load pressure regulator of the aircraft, the ring 3 is set at the front end of the rod body 1, the weight body 16 is a cavity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com