Adsorption buffer

A buffer device and moving shaft technology, which is applied in the direction of transportation and packaging, conveyor objects, conveyors, etc., can solve the problems of positioning accuracy degradation, dust falling, and trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

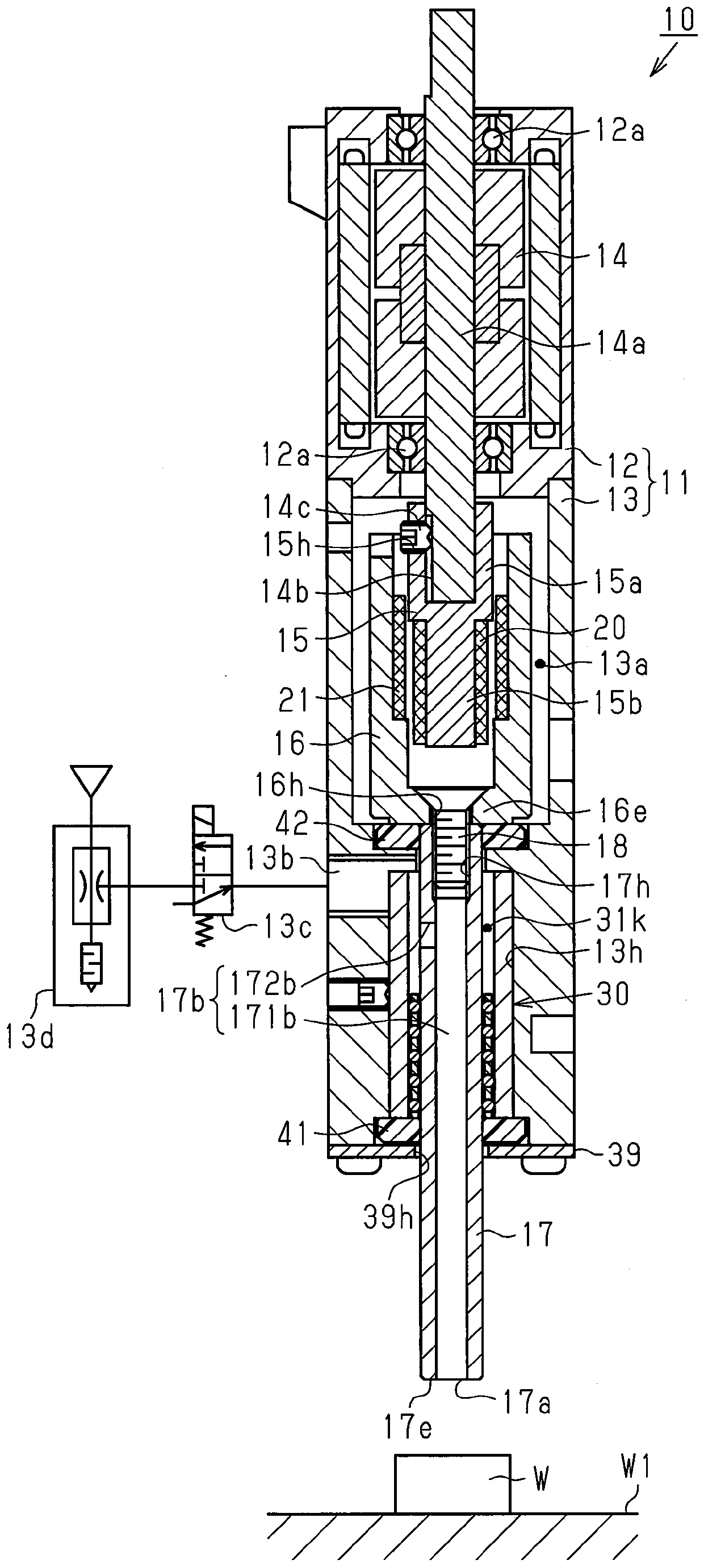

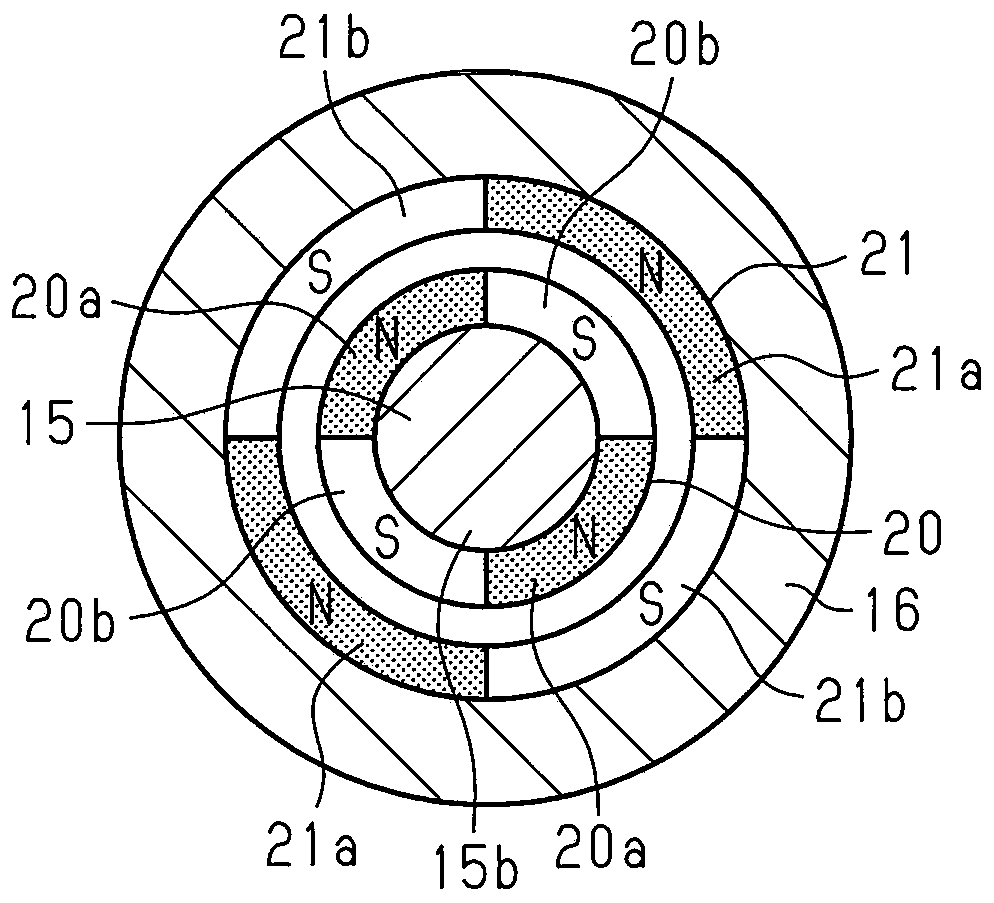

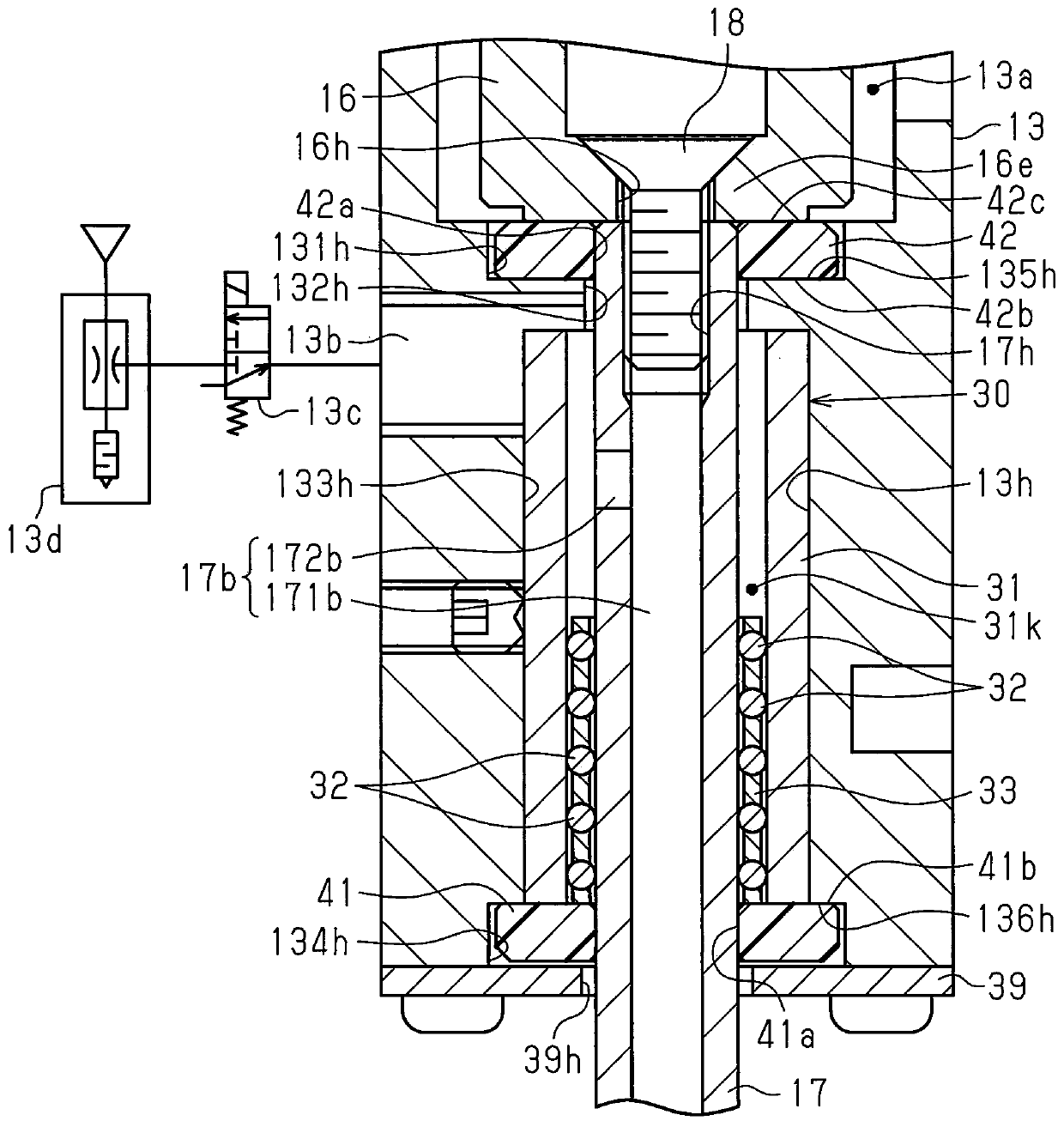

[0032] Follow the figure 1˜ FIG. 7 illustrate an embodiment of the present invention in which an adsorption buffer device is embodied. The suction cushioning device of this embodiment suctions objects to be conveyed, such as electronic components. In addition, the suction cushioning device is used attached to the tip of an XYZ actuator not shown.

[0033] like figure 1 As shown, the housing 11 of the suction cushioning device 10 has a motor housing 12 and a cylindrical main body housing 13 connected to the motor housing 12 . A rotor 14 of the electric motor is housed in the motor housing 12 , and the rotor 14 has a rotating shaft 14 a. The main body case 13 is coupled to the motor case 12 such that the axial direction of the main body case 13 coincides with the axial direction of the rotary shaft 14a.

[0034] The rotating shaft 14a is rotatably supported by the motor case 12 via the bearing 12a. Both ends of the rotating shaft 14 a pass through the motor case 12 and pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com