Angle-adjustable socket

A technology of sockets and angles, which is applied to the parts of connecting devices, flexible/rotatable wire connectors, electrical components, etc., can solve the problems of inability to adjust the size, hidden dangers, fixed socket volume, etc., so that it is not easy to dump and has good stability , to avoid the effect of excessive bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

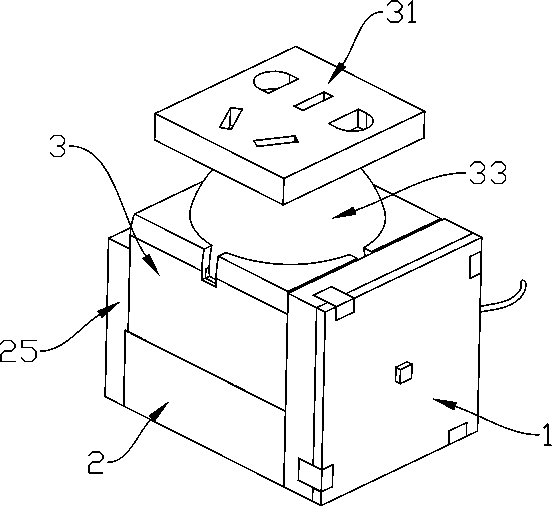

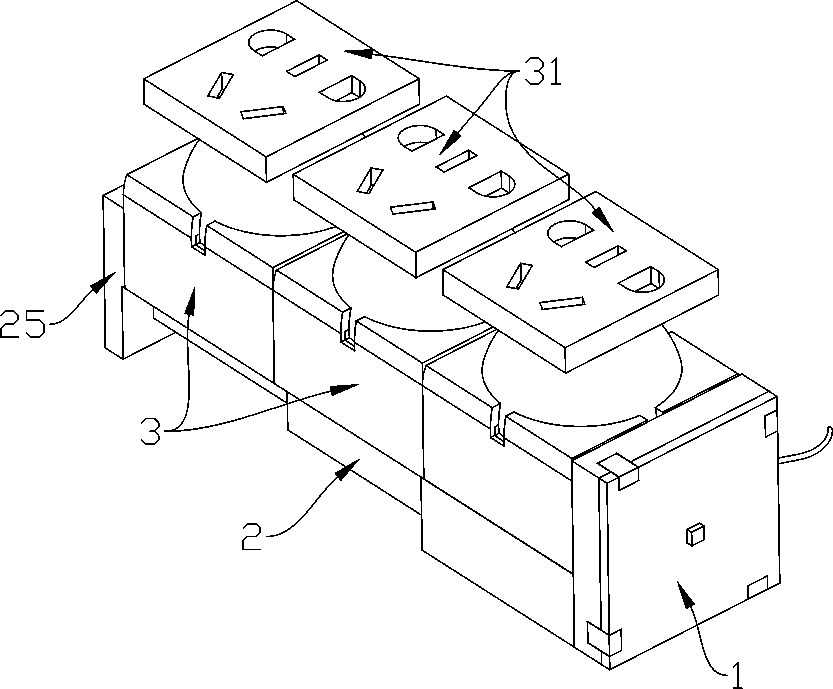

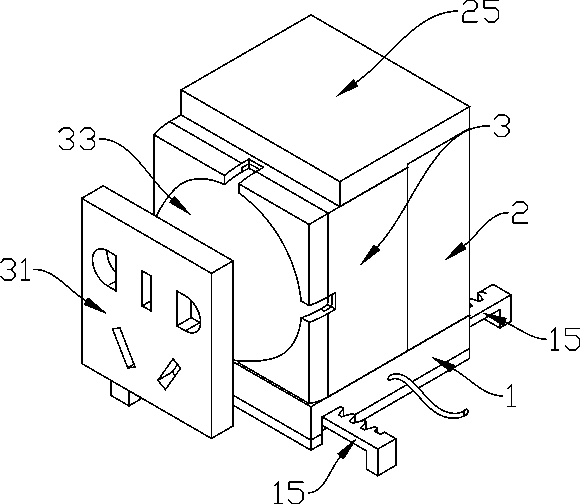

[0028] refer to Figure 1 to Figure 13 , an angle-adjustable socket, including a base module 1, a telescopic module 2, a socket module 3, and a conductive assembly, wherein the specific structure is as follows.

[0029] The base module 1, the base module 1 includes a first cover plate 11 and a second cover plate 12 fitted together, a base cavity is provided between the first cover plate 11 and the second cover plate 12, the base The center of the seat cavity is provided with a rotatable gear 14, and the periphery of the base cavity is provided with several racks 15 meshing with the gears 14. The racks 15 can protrude from the side of the base module 1, and the racks 15 The protruding end is used for support; the center of the gear 14 is provided with a rotating shaft installation hole 141, and a synchronously rotating rotating shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com