LED driver and LED lighting device

An LED driver and node technology, applied in the field of light source driver design, can solve problems such as low driving efficiency, poor load regulation, and LED light source load damage, and achieve the effect of excellent load regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] As mentioned in the background art section, the LED driver that can be used to drive the LED light source in the prior art cannot take into account both the driving efficiency and the load regulation rate, and cannot meet the market demand.

[0030] The inventor of the present application analyzed an LED driver using a series resonance scheme in the prior art.

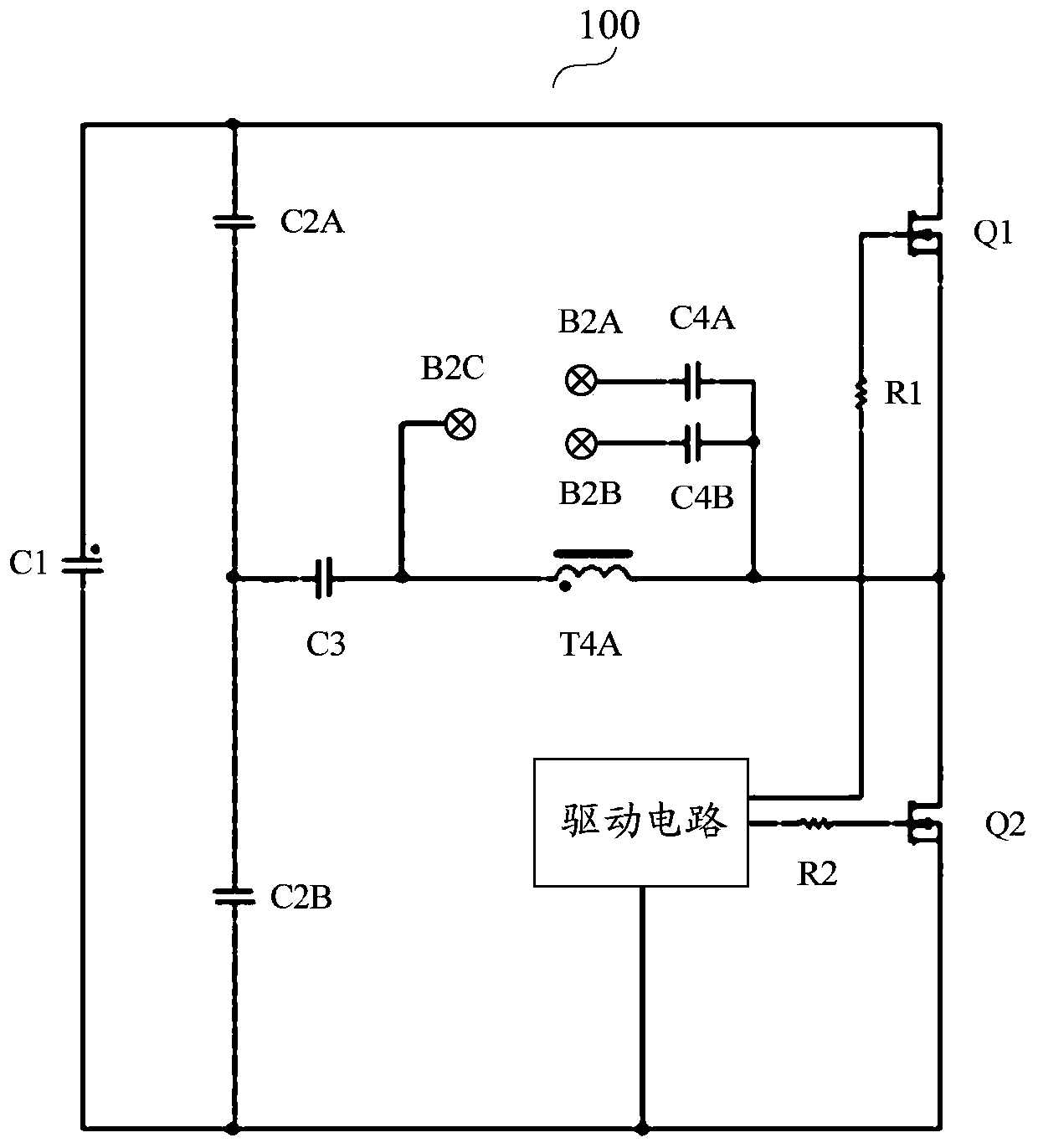

[0031] figure 1 It is a schematic structural block diagram of an LED driver in the prior art. Such as figure 1As shown, the LED driver 100 in the prior art may include a half-bridge circuit composed of a capacitor C2A, a capacitor C2B, a switch tube Q1 and a switch tube Q2, an electrolytic capacitor C1, current limiting resistors R1 and R2, a driving circuit, and a series resonance The capacitor C3 and the inductor T4A of the circuit, the LED load (not shown in the figure) and the current-limiting capacitors C4A and C4B connected in parallel to both ends of the inductor T4A. figure 1 The shown LED load includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com