Control circuit and control method of high-side depressurization converting circuit

A technology for converting circuits and controlling circuits, which is applied in the field of circuits, can solve problems such as differential load regulation, and achieve good load regulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

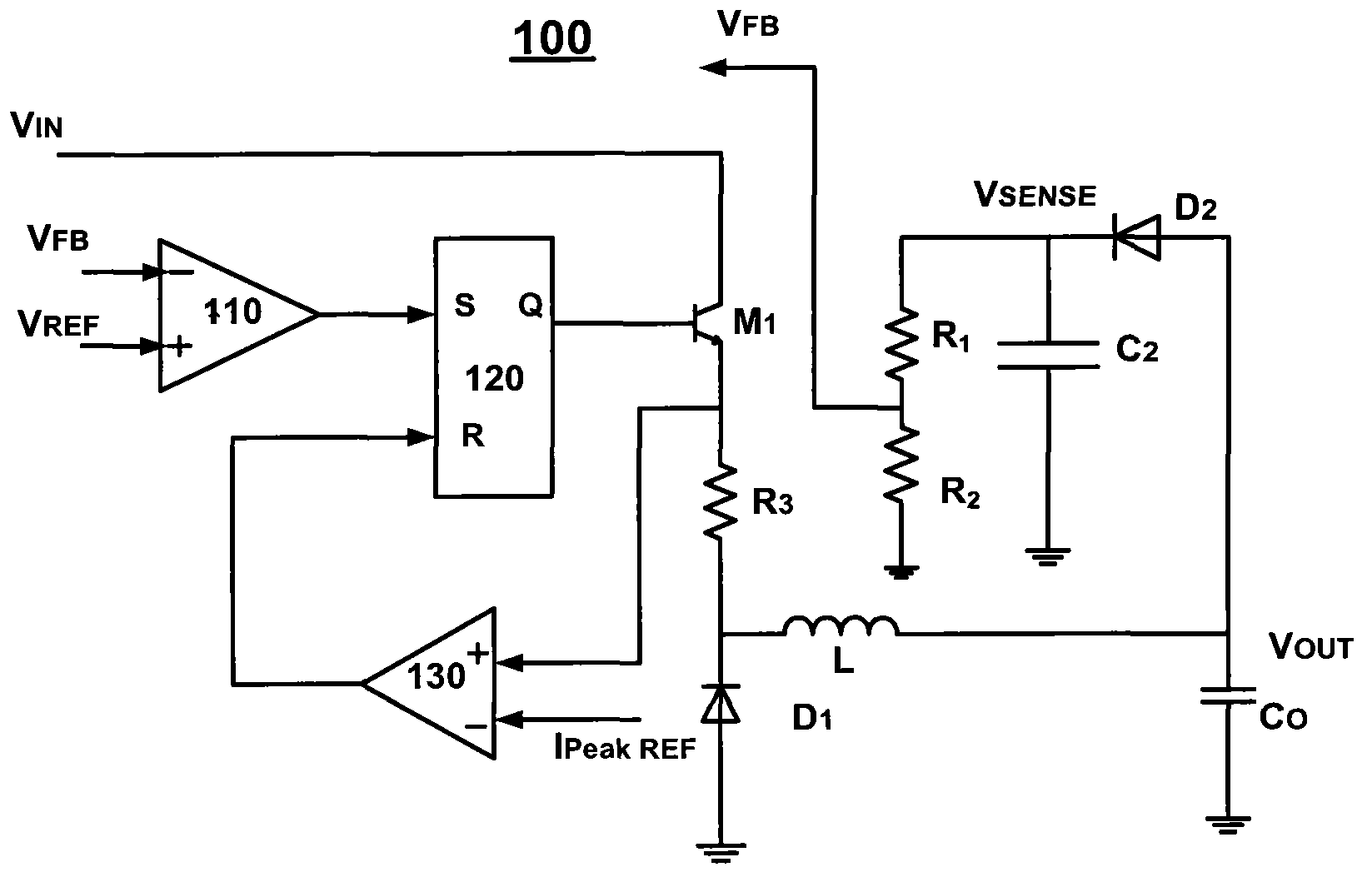

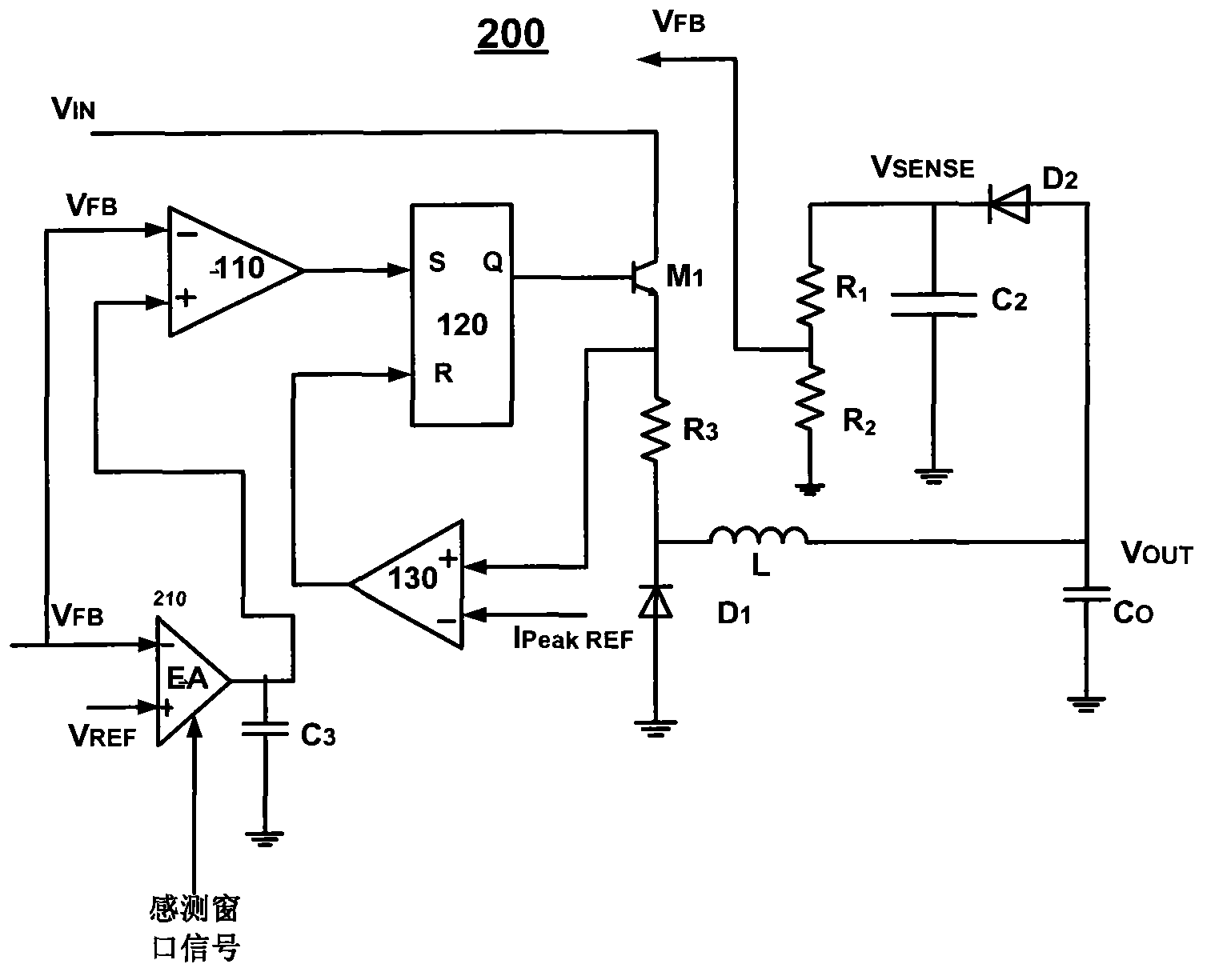

[0028] figure 2 A COT system 200 according to one embodiment of the invention is shown.

[0029] and figure 1 Compared to the COT system 100 shown in the figure 2 The COT system 200 shown adds a loop. More specifically, the COT system 200 includes an error amplifier 210 with a compensation capacitor C connected in parallel at its output 3 .

[0030] exist figure 2 In the illustrated embodiment, the error amplifier 210 is a transconductance amplifier. Of course, those skilled in the art should understand that other types of error amplifiers are also applicable in the present invention.

[0031] In system 200, the feedback signal V FB is input to the inverting input terminal of the error amplifier 210 and the inverting input terminal of the first comparator 110 . The non-inverting input terminal of the error amplifier 210 receives the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com