Precise casting coating stirrer

A technology of precision casting and agitator, which is used in mixer accessories, mixers with rotary stirring devices, chemical instruments and methods, etc., can solve the problems of increasing the probability of danger, different diameters of paint buckets, and reducing the stirring effect, etc. To achieve the effect of improving the quality of mixing products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

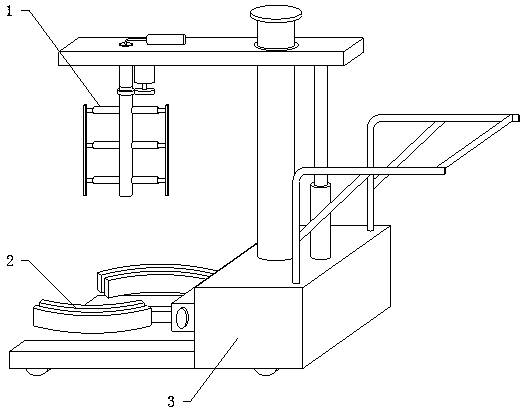

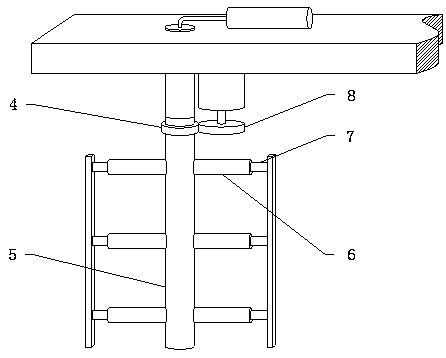

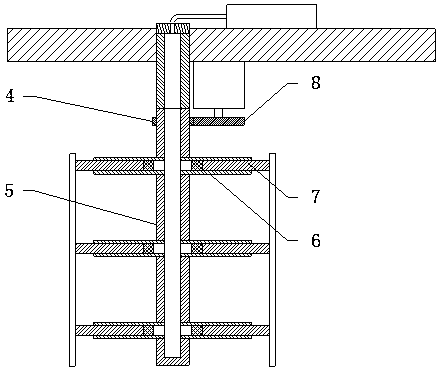

[0021] see Figure 1 to Figure 4 , the present invention provides a technical solution: a precision casting paint mixer, including a functional mechanism 1, a fastening mechanism 2 and a load-bearing seat 3, the lower end of the functional mechanism 1 is provided with a load-bearing seat 3, and the left end of the load-bearing seat 3 is equipped with a fastening mechanism 2. There is a functional mechanism 1 above the fastening mechanism 2. The functional mechanism 1 includes a ring gear 4, a hollow shaft 5, a hollow stirring rod 6, an extension rod 7 and a transmission gear 8. The fastening mechanism 2 includes an arc-shaped rubber pad 9, an arc Shape splint 10, spring 11, shell 12 and two-way screw mandrel 13.

[0022] In the functional mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com