A defrosting device and defrosting method for cold storage pipes

A technology of cold storage and hoses, which is applied in the field of defrosting devices for cold storage pipes, which can solve the problems of cumbersome process and inconvenient use, and achieve the effect of no cooling loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

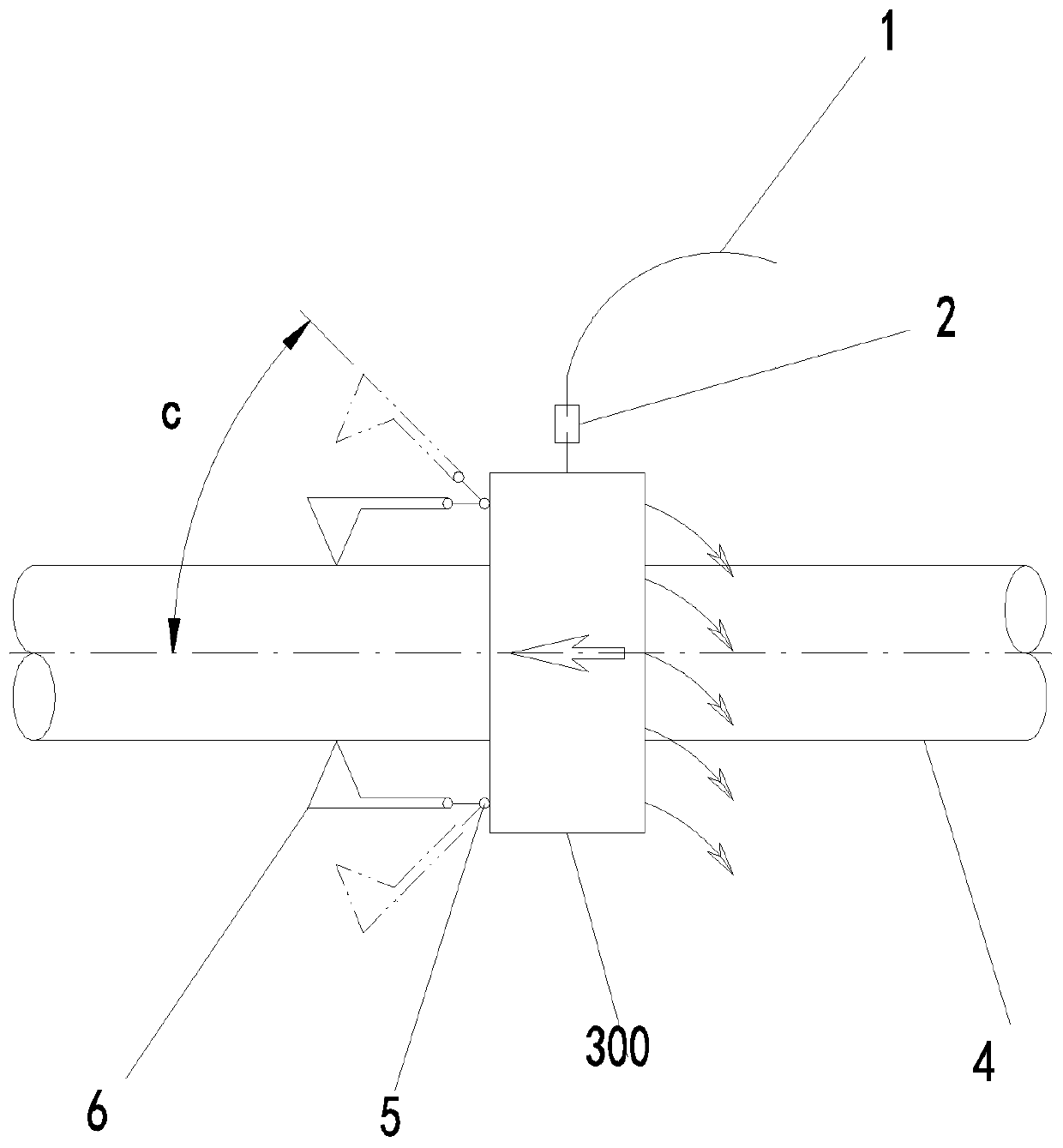

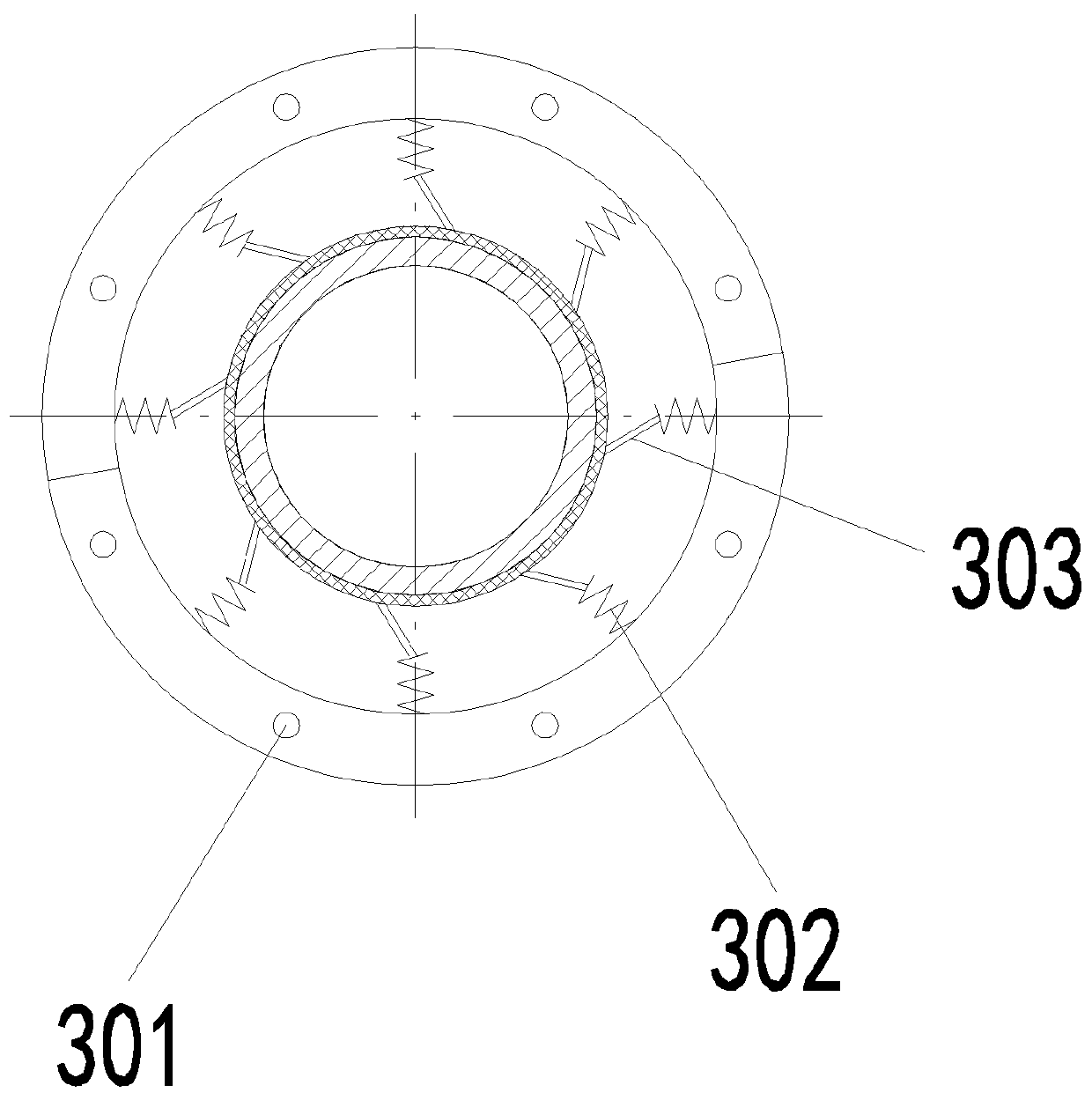

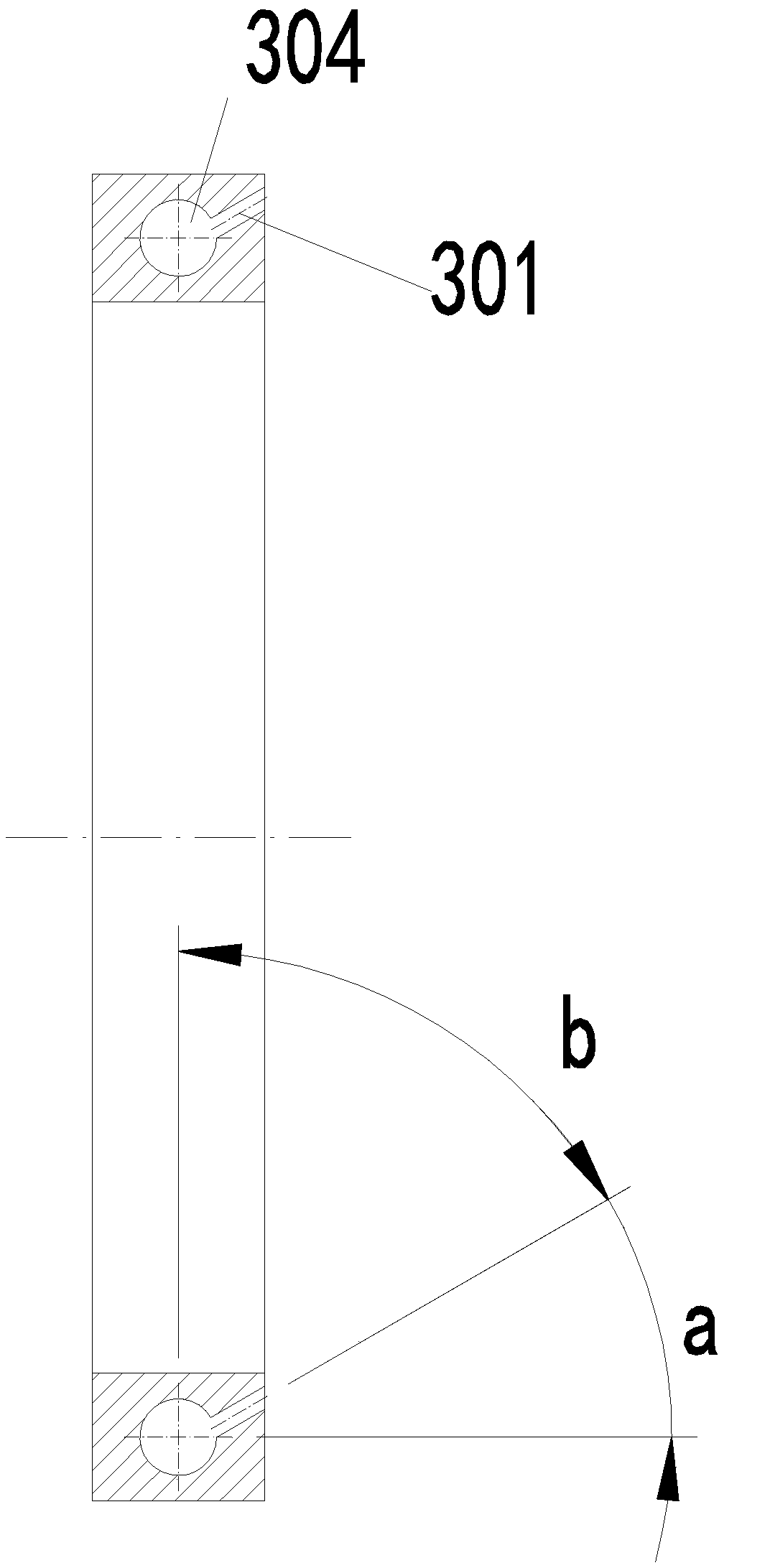

[0028] Reference attached Figure 1 to Figure 3 As shown, the present invention provides a cold storage pipe defrosting device and defrosting method, specifically: including flexible hose 1, universal movable joint 2, smooth pipe 4, connecting mechanism 5, cone head (using acute angle Cone head 6, the sharp cone head can hit the ice layer more powerfully) and the rotating scraper holder 300. The rotating scraper holder 300 mainly includes a rotating scraper ring. The rotating scraper holder 300 has air jet holes 301 and elastic parts (the elastic parts are originally designed with springs). 302, but not limited to this), scraper 303. The scraper 303 is fixed on the spring 302, and the spring 302 is fixed on the body of the 300. Each scraper is connected to a spring. The spring and the scraper are evenly distributed along the concentric circle of the rotating scraper holder. The number is more than four. The center of the concentric circle is to each scraper. The distances betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com