A drying machine for printing

A drying machine and skateboard technology, which is applied in the field of drying machines, can solve problems affecting the health of operators and poor uniformity of the photosensitive plate, and achieve the effects of avoiding harmful gases from escaping, ensuring health, and uniform operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following is further described in detail through specific implementation methods:

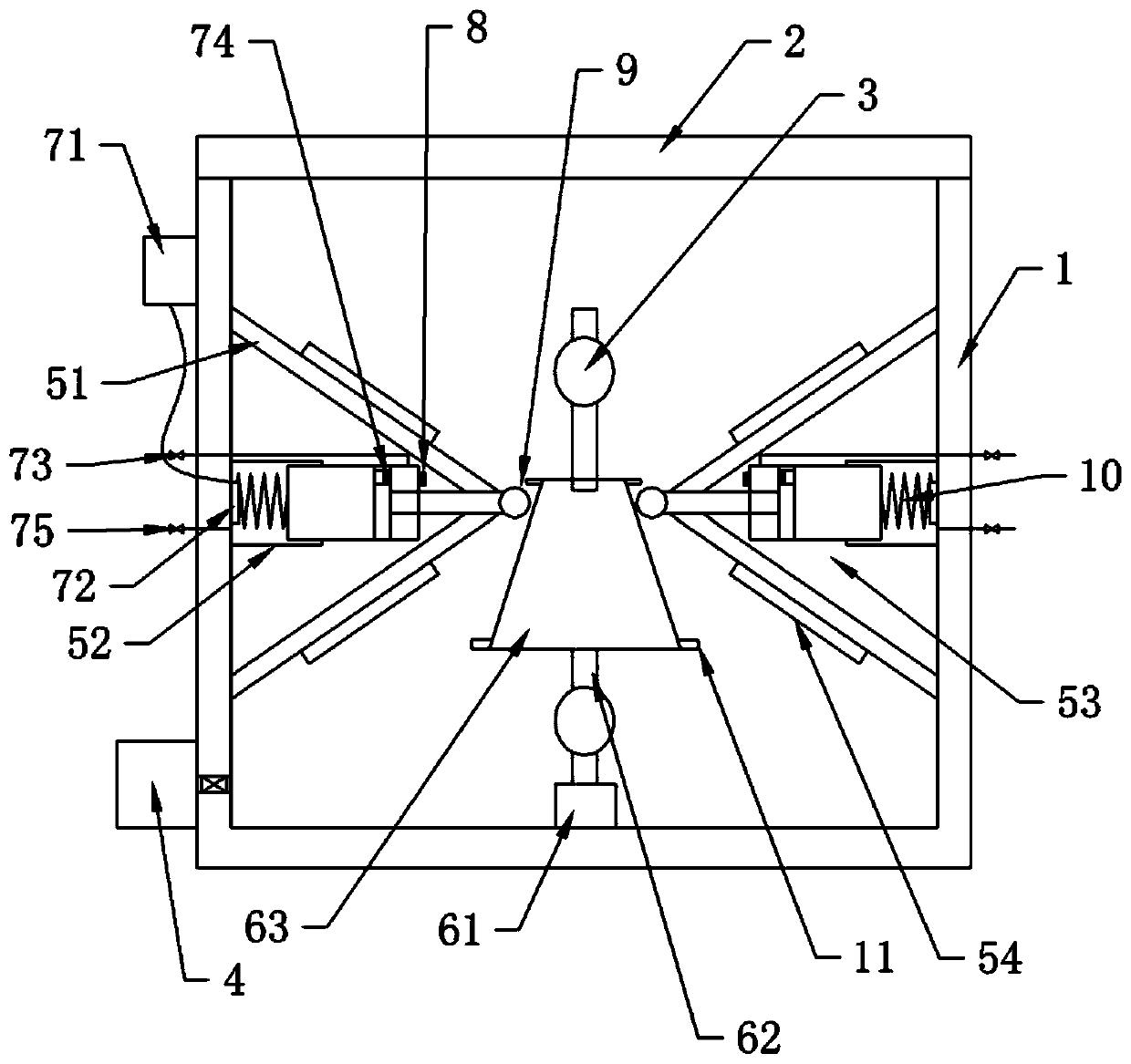

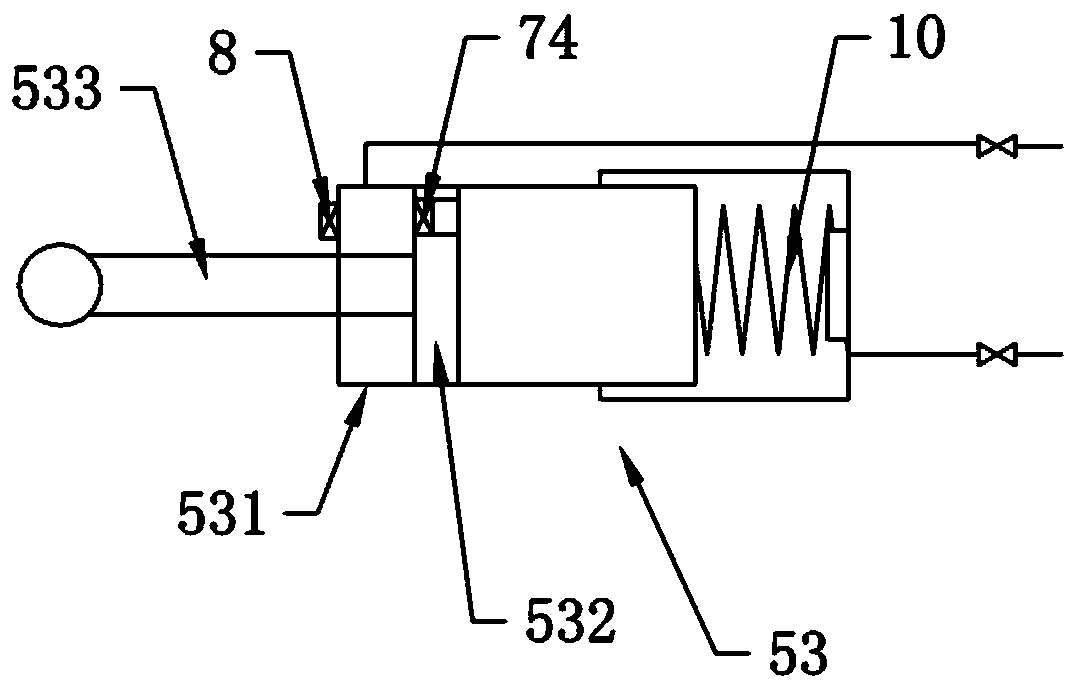

[0026] The reference signs in the drawings of the description include: chassis body 1, sealing cover 2, ultraviolet lamp 3, vacuum pump 4, slide plate 51, sliding seat 52, suction piece 53, suction cylinder 531, piston body 532, driven rod 533 , drying board unit 54, power source 61, telescopic rod 62, driver 63, controller 71, pressure sensor 72, first electric control valve 73, second electric control valve 74, third electric control valve 75, one-way inlet Air valve 8, scroll wheel 9, spring 10, limit block 11.

[0027] The embodiment is basically as attached figure 1 Shown:

[0028] A drying board machine for printing, comprising a case body 1, an ultraviolet lamp 3, a vacuum pump 4 and a sealing cover 2 for covering the case body 1, the suction port of the vacuum pump 4 communicates with the lower part of the case body 1 through a pipeline, and the upper part of the pipeline i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com