Electronic parts moving device and electronic parts conveying device

A technology of electronic parts and mobile devices, which is applied in the field of electronic parts mobile devices, and can solve problems such as the inability to advance and retreat the configuration of drive devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

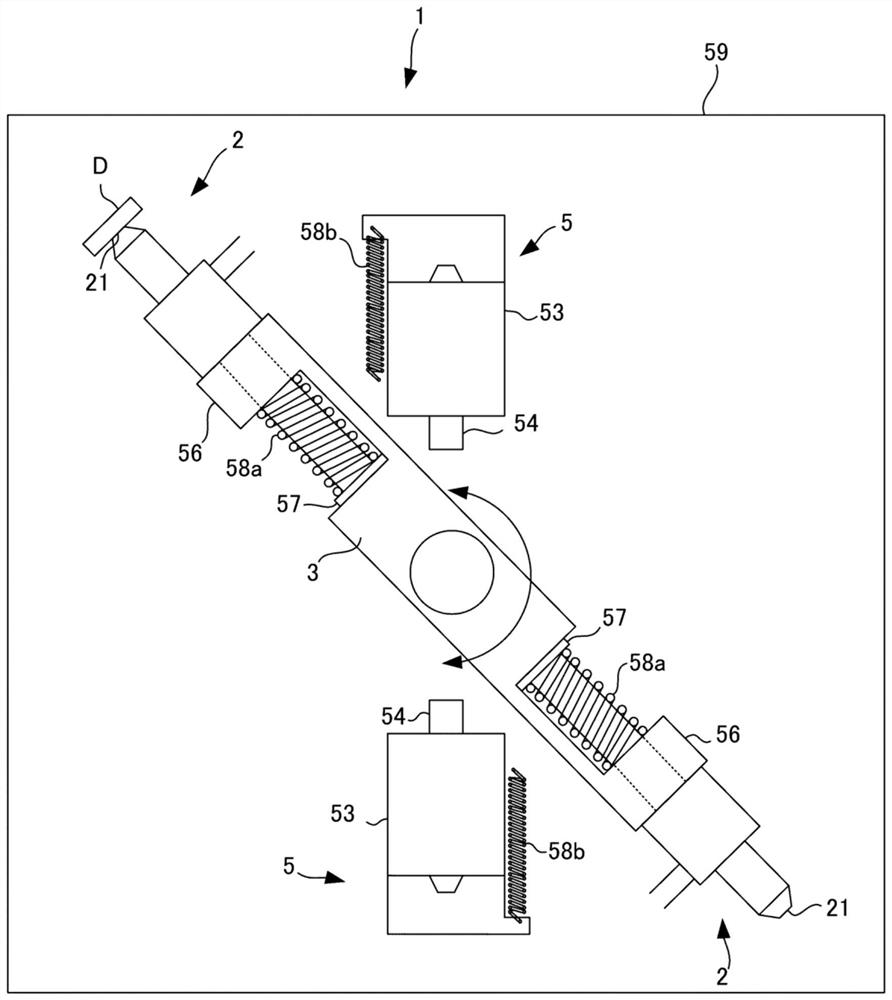

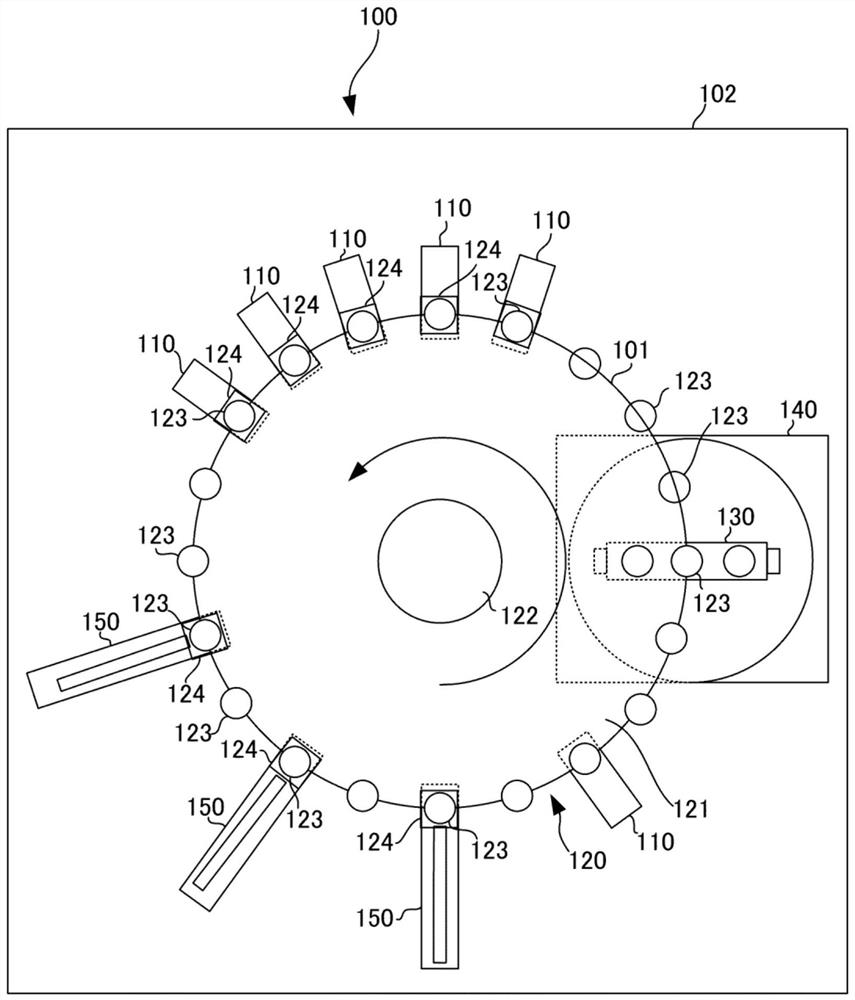

[0044] Hereinafter, embodiments and application examples of the electronic component moving device of the present invention will be described in detail with reference to the drawings.

[0045] figure 1 as well as figure 2 The illustrated electronic component moving device 1 is also called a rotary pickup (Rotary pickup) according to the original purpose of use. This electronic component moving device 1 rotates and moves the electronic component D so as to draw a circular trajectory or an arc trajectory. Moreover, the electronic component moving apparatus 1 stops temporarily so that the electronic component D may be processed in the middle of a movement track, or the start and end of a movement track. Such an electronic component moving device 1 may include a suction nozzle 2 , a rotor (rotor) 3 , and a motor 4 .

[0046] The suction nozzle 2 is an example of a holding unit that holds the electronic component D. As shown in FIG. The suction nozzle 2 has a cylindrical shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com