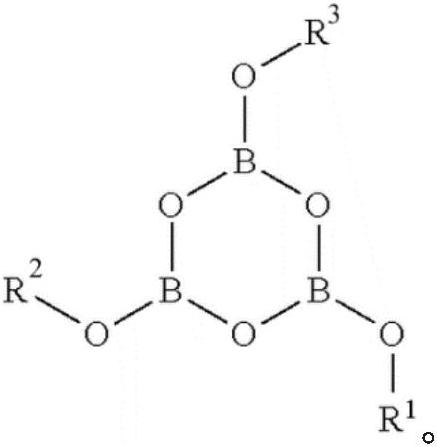

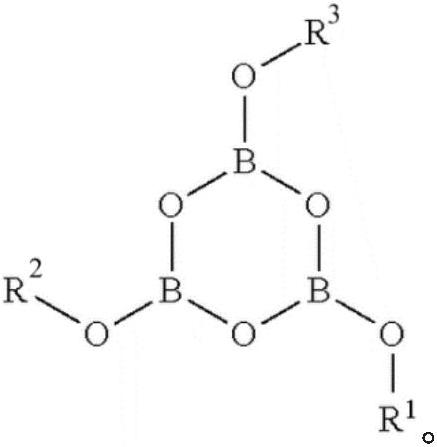

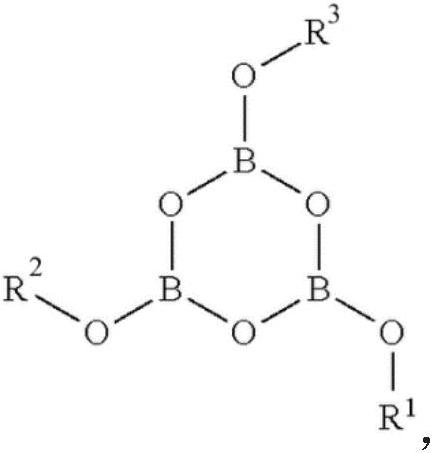

Boroxane-Based Seal Compatibilizers

A technology of sealing compatibility and sealing parts, which is applied in the direction of additives, compounds containing elements of group 3/13 of the periodic table, organic chemistry, etc., and can solve problems such as hydrolysis sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0050] This example illustrates long chain alkoxyboroxanes that have demonstrated the ability to improve the performance of dispersants on FKM elastomers in static seal testing. See ASTM D1418. The dodecanol (about C12) form of boroxane was synthesized as follows:

[0051] A 500 mL round bottom flask equipped with a dean stark apparatus and under nitrogen was charged with 200 mL of toluene. To this was added 1 mole of boric acid. At 70°C, 1 mole of dodecanol was added in one portion and the reaction mixture was then heated to reflux. The reaction mixture was kept at reflux for at least 4 hours and 2 moles of water were collected. The Dean Stark trap was replaced with a short path distillation head and the toluene was removed by distillation. Once the solvent was removed, the reaction mixture was continued to dry by drawing a vacuum of 28 mmHg for 2 hours while increasing the temperature to 140°C. Once held for 2 hours, the product (Product 1) was removed from the heat and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com