Inflating method of packing box self-sealing valve for packing box

A packaging box and valve technology, applied in the direction of pressurization/gasification packaging, etc., can solve the problem of slow air leakage at the inflation port of the packaging box, and achieve the effects of short manufacturing cycle, simple solution, and air tightness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

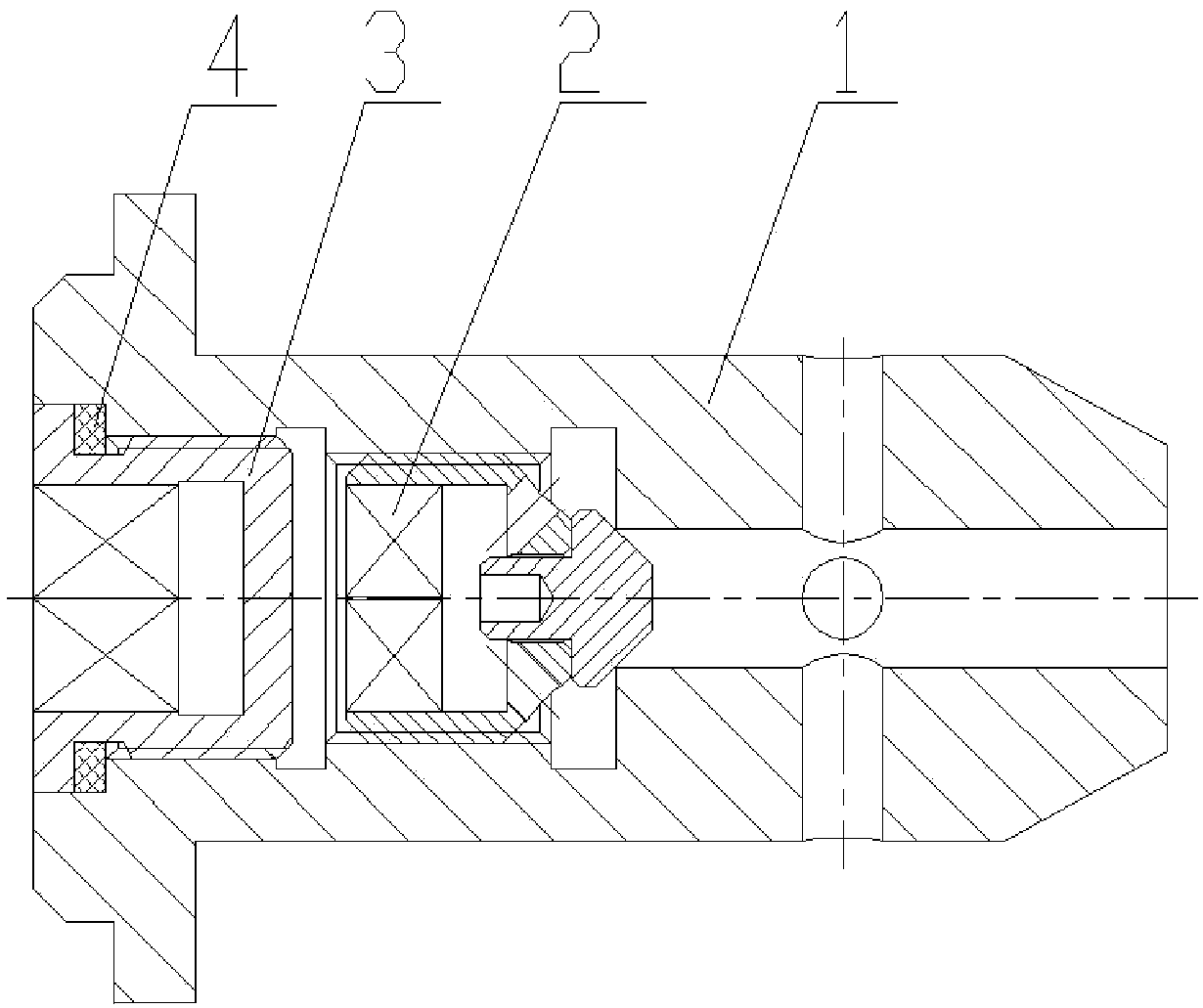

[0038] Such as figure 1 As shown, the packaging box self-sealing valve of the present invention is used to inflate a packaging box, wherein the packaging box self-sealing valve is composed of a valve seat 1, a valve 2, a screw plug 3, and a sealing ring 4. The self-sealing valve of the packing box is welded on the wall of the packing box; the packing box can be inflated by unscrewing the valve 2, and the packing box can be kept self-sealing by tightening the valve 2.

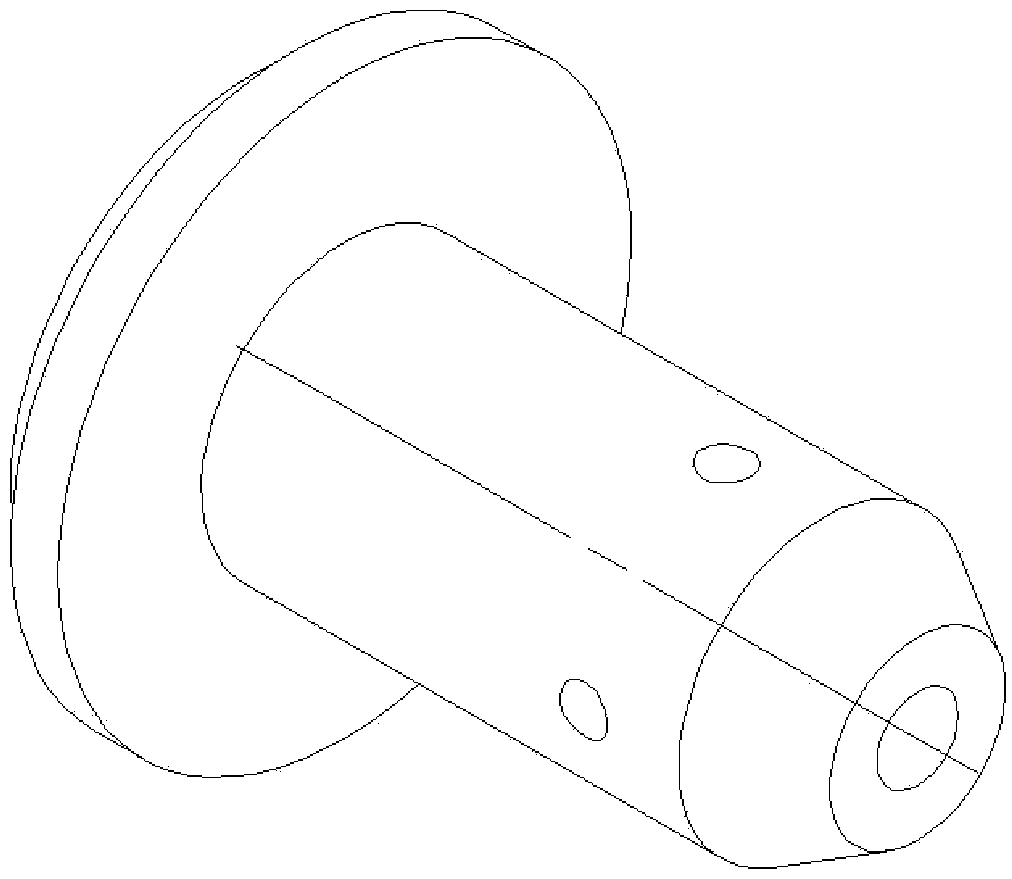

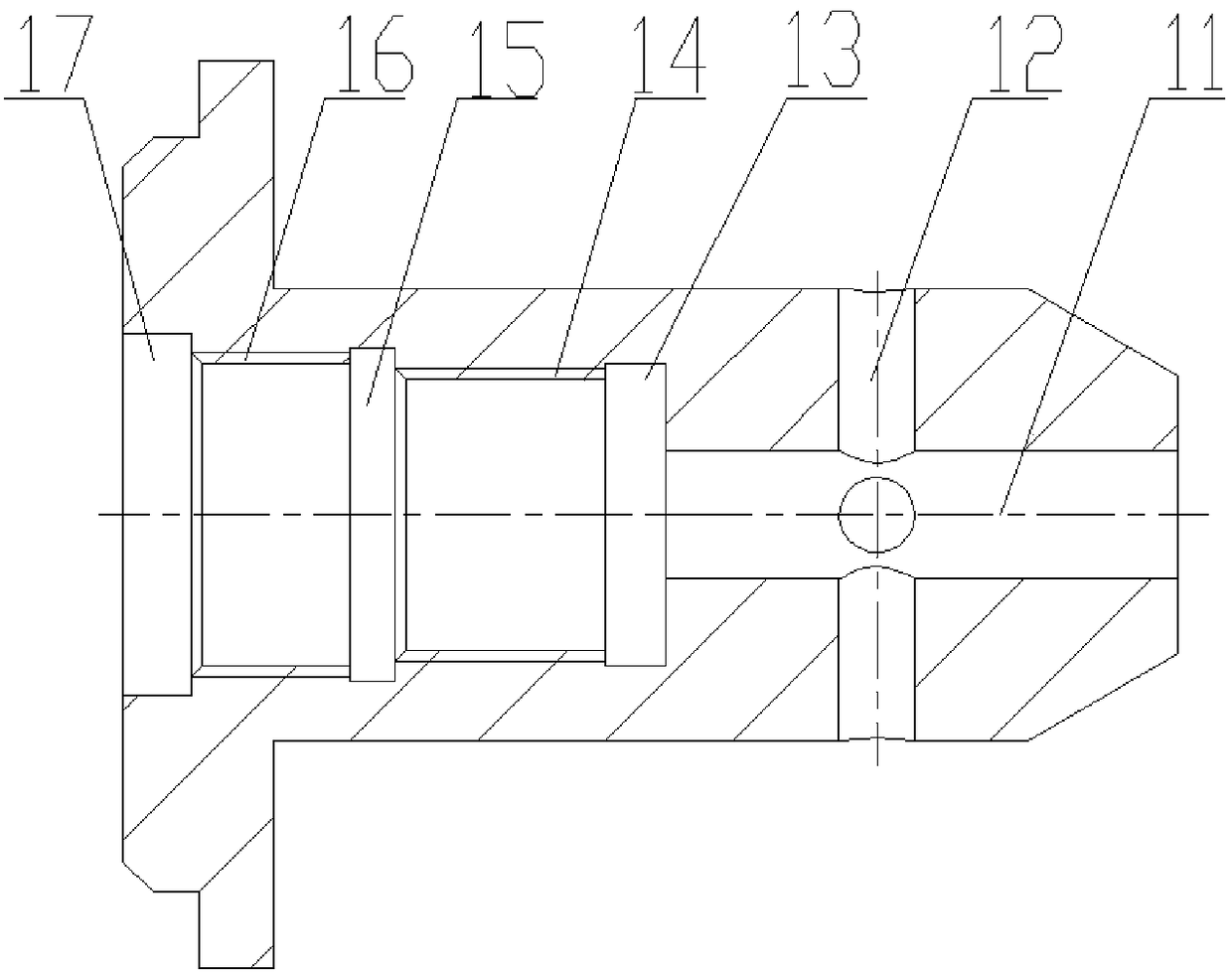

[0039] Such as figure 2 , image 3 Shown, the valve seat 1 is generally a T-shaped cylindrical structure, the left side is two cylinders with different diameters, the middle is a cylinder, and the right end is a circular platform (i.e. a truncated con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com