A new composite sandwich panel connection structure without metal connectors and its design method

A composite material and connecting structure technology, applied in chemical instruments and methods, layered products, glass/slag layered products, etc., can solve the problem of inability to meet the requirements of use, reduced weight reduction effect of composite materials, and low extrusion strength in the connection area. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

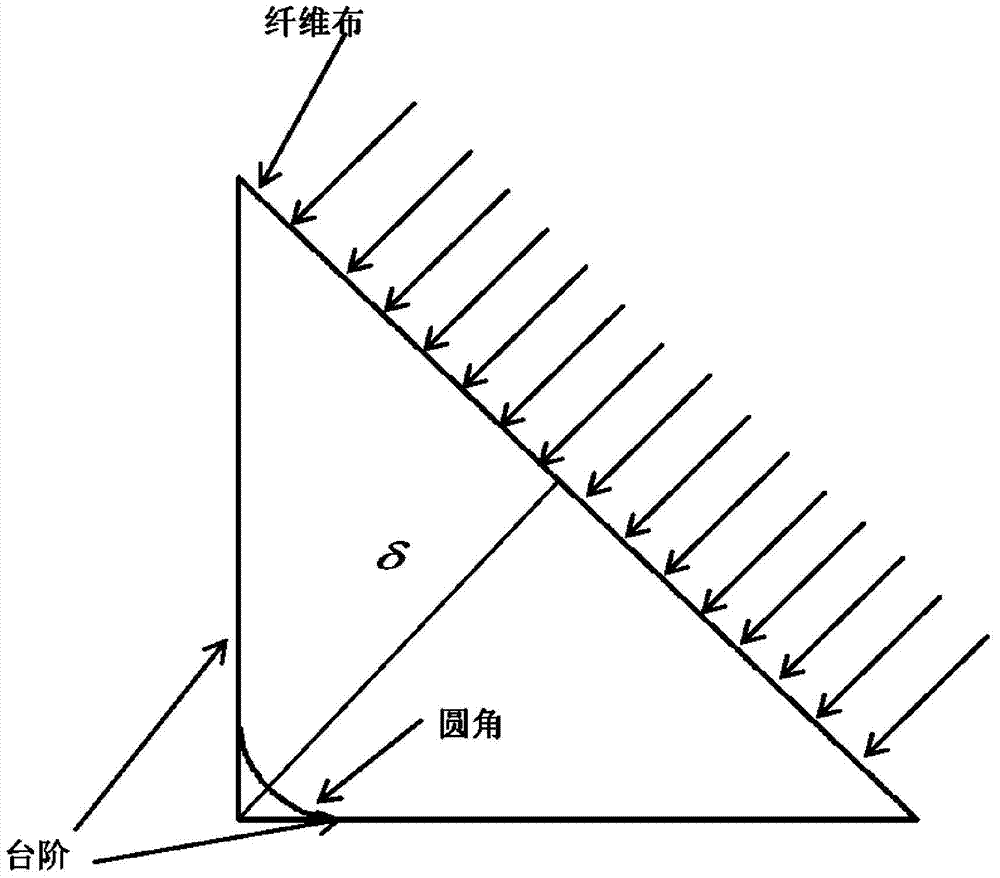

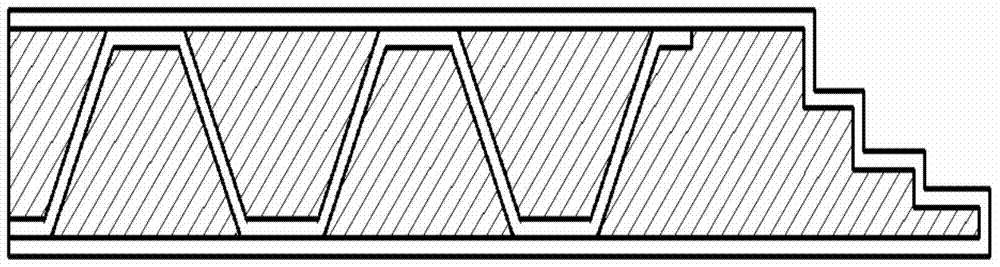

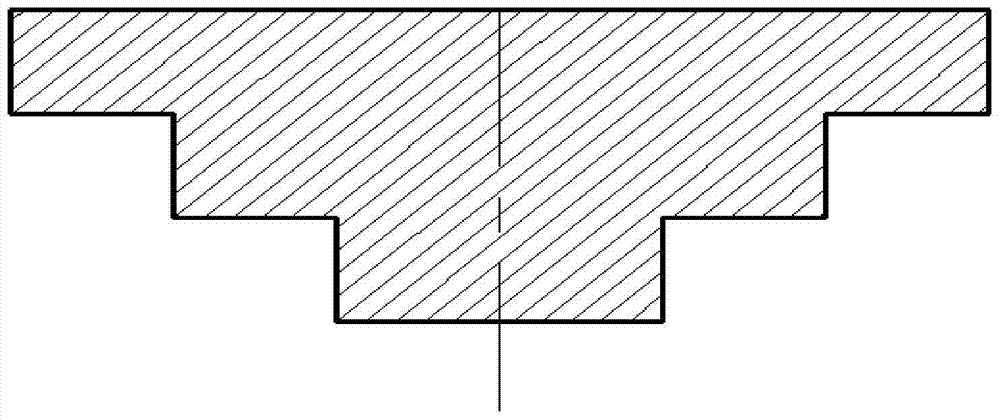

[0067] Such as Figure 1 to Figure 9 , a new type of composite sandwich panel connection structure without metal connectors, including glass fiber cloth 1A, PVC foam core 1B, composite sandwich panel 1, composite material connector 2 and composite material rib 3, glass fiber cloth 1A prepares composite sandwich panels 1, composite connectors 2 and composite reinforcement ribs 3 by cross-laminating PVC foam core 1B at 0 and 90 degrees, and prepares composite sandwich panel connection structures by secondary bonding.

[0068] A new composite sandwich panel connection structure without metal connectors, including glass fiber cloth 1A, PVC foam core 1B, composite sandwich panels 1, composite connectors 2 and composite ribs 3, composite sandwich panels 1 Covering and setting on the outer surface of the plate structure composed of glass fiber cloth 1A and PVC foam core 1B to form a sandwich panel unit structure, and the sandwich panel unit structure is connected by composite materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com