Stacker pallet blockage prevention direction adjusting device

A direction adjustment and stacking machine technology, applied in the field of stacking machines, can solve the problems of abnormal height of workpieces in the stacking direction, affecting the operation effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

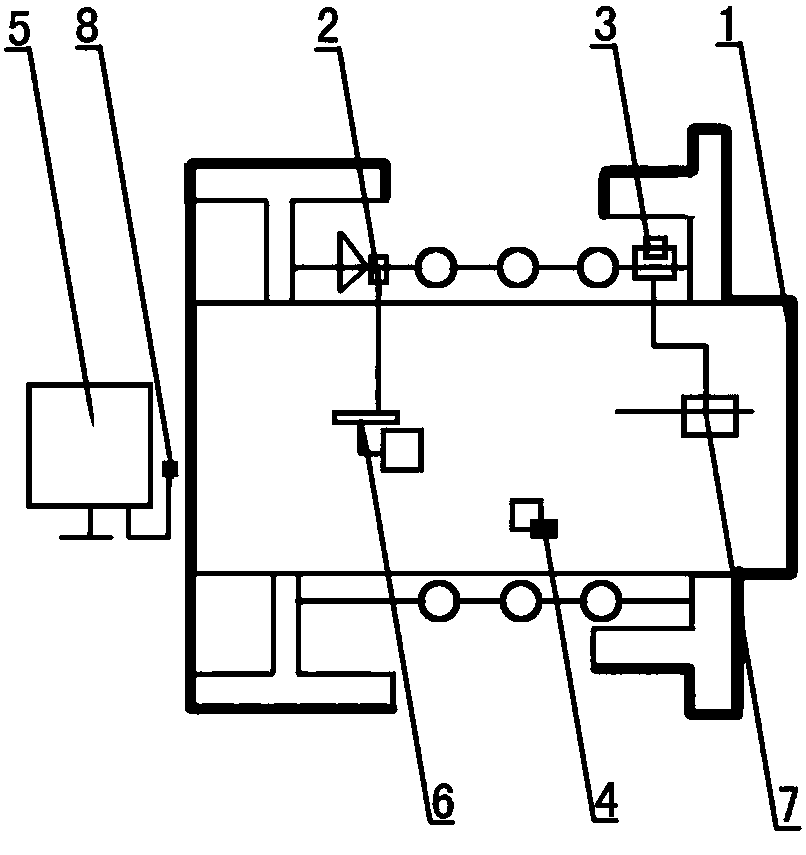

[0012] Embodiment: as shown in the accompanying drawing. The stacking machine pallet jam prevention direction adjustment device includes a body (1), on which an upper workpiece steering module (2), an infrared sensor module (3), a remote communication module (4), a management module (5), during operation, the workpiece steering module (2) is arranged at the place where the workpiece is placed, the infrared sensing module (3) senses the height of the workpiece, and the remote communication module (4) transmits the sensed information to the management module (5 )deal with.

[0013] The stacking machine pallet jam prevention direction adjustment device is provided with a direction reference module (6) on the workpiece steering module (2), and according to the direction of the workpiece, it is referred to whether the parts of the fuselage are consistent.

[0014] The stacking machine pallet jam prevention direction adjustment device is provided with a height limiting module (7) o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com