Thrust bearing and holder used for thrust bearing

A technology for thrust bearings and cages, applied in the field of cages, can solve problems such as reverse installation of thrust needle roller bearing cages, and achieve the effect of reversing cages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

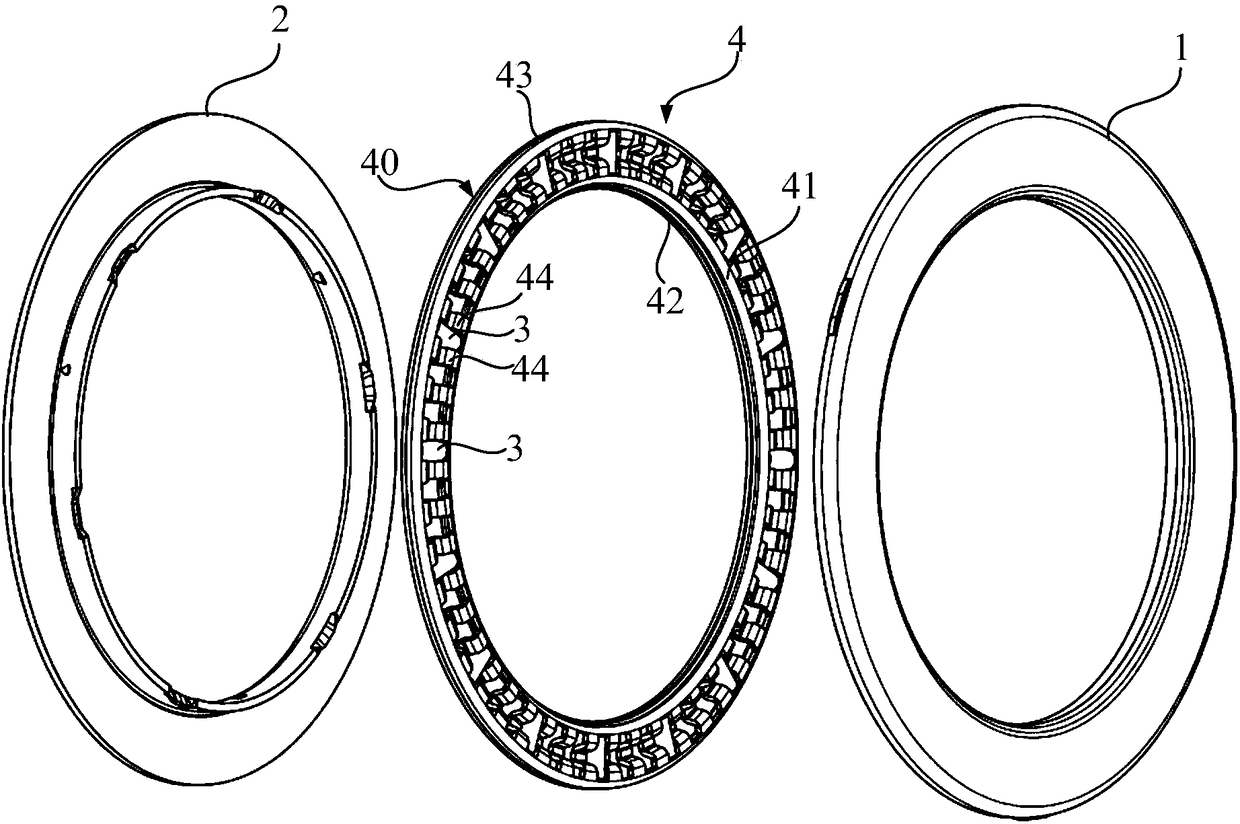

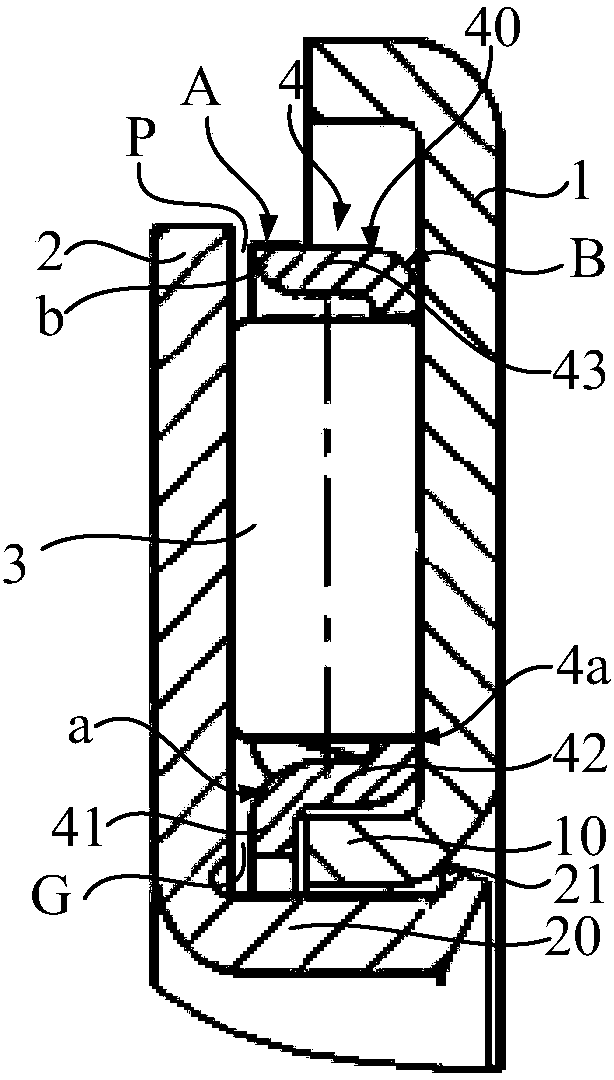

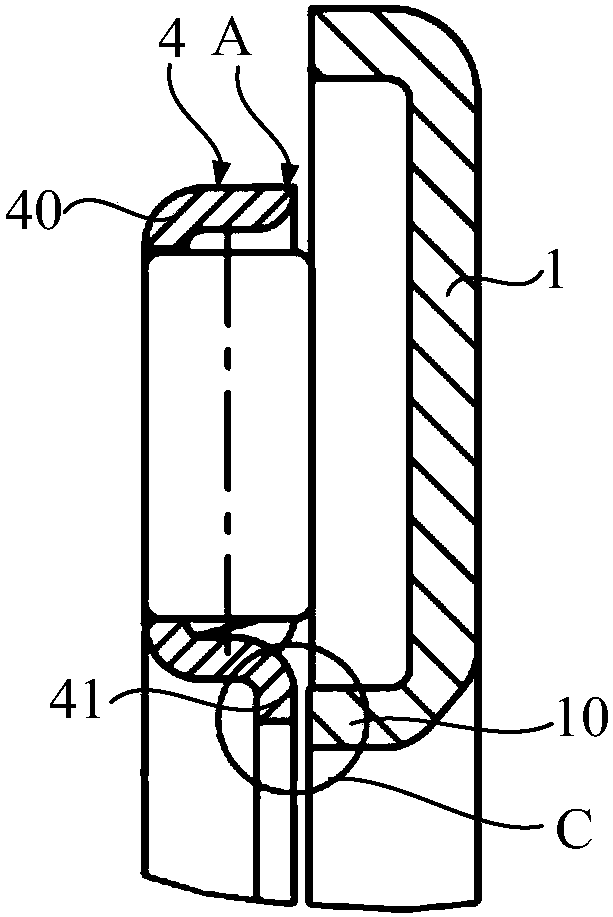

[0028] refer to figure 1 and figure 2 , the thrust bearing may include: a first washer 1 and a second washer 2 arranged axially and a number of rolling elements 3 arranged between the first washer 1 and the second washer 2, the first washer 1 has a direction toward the second washer 2 The axially protruding first protruding ring 10 and the rolling elements 3 are arranged along the circumferential direction of the thrust bearing, and the first washer 1 and the second washer 2 can realize relative rotation through the rolling elements 3 . The thrust bearing may also comprise a cage 4 in which the rolling elements 3 are defined.

[0029] The cage 4 includes: a body frame 40, which has an inner peripheral surface and an outer peripheral surface, and the two axial ends are respectively a first end A and a second end B; a radial inner protrusion 41 is connected to the first end A, and The body frame 40 is radially inwardly higher than the inner peripheral surface of the body fram...

no. 2 example

[0045] refer to Figure 5 , The cage 5 in this technical solution includes: a radially outer protrusion 51 connected to the first end A′, and the outer protrusion 51 can be higher than the outer peripheral surface of the body frame 50 radially outwards along the body frame 50 . Therefore, when the cage 5 is correctly assembled in the thrust bearing, the first washer 6 also has a third collar 60 surrounding the body frame 50, and the outer protrusion 51 is at least partially axially opposite to the third collar 60, so that the body frame 50 Can be accommodated between the first collar 10 and the third collar 60 .

[0046] During assembly, if the retainer 5 is reversed, the outer protrusion 51 will interfere with the third protruding ring 60 , so that the retainer 5 cannot be installed on the first washer 6 . Therefore, the retainer 5 of the present technical solution can avoid the problem of reverse installation of the retainer 5 .

[0047] Referring to the shape of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com