Direct-heat-type heater

A direct heating heater technology, applied in the mechanical field, can solve the problems of uneven water temperature, low ceramic heat dissipation capacity, and low heat transfer efficiency, and achieve uniform water temperature, fast heating speed, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

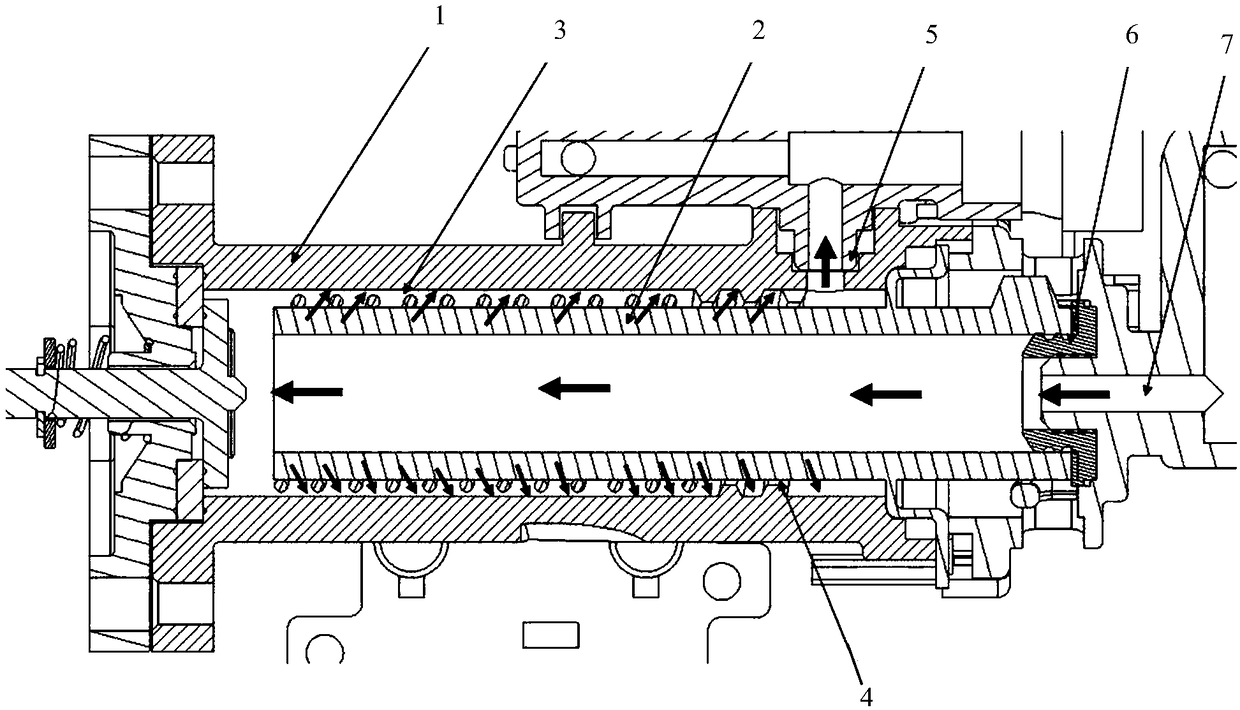

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] refer to figure 1 , this embodiment proposes a direct heating heater, including:

[0026] The direct heating heater housing 1, the heating device 2 arranged inside the direct heating heater housing 1 and the direct heating heater components;

[0027] At least one section of the heating device 2 is equipped with a metal elastic device 3 , and the inner wall of the direct heating heater shell 1 corresponding to the heating device 2 without the metal elastic device 3 is partially or completely provided with a spiral groove structure 4 .

[0028] In the prior art, the water flow quickly passes through the cavity formed by the ceramic heating tube and the shell of the heater, and the heat energy is directly transferred from the ceramic heating tube to the flowing water. Due to the relatively low heat dissipation capacity of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com