A kind of y-containing high-abundance rare earth permanent magnet and its preparation method

A rare earth permanent magnet, high abundance technology, used in magnetic objects, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of reduced coercivity and remanence, deterioration of magnet microstructure, etc., to compensate for coercivity Loss of force, effect of enhanced anisotropy field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

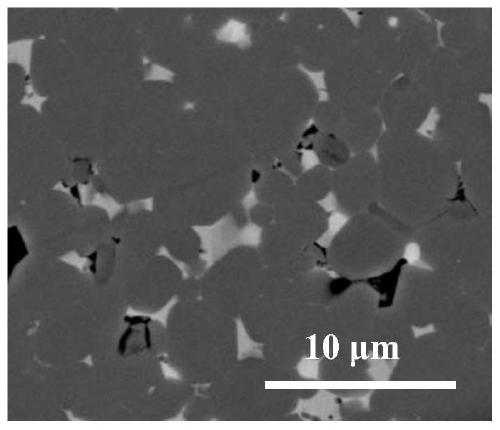

[0038] In this embodiment, the high-abundance rare earth permanent magnet is expressed in mass percent, and its nominal composition is: [Nd 0.5 Ce 0.5 ] 30.5 Al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0039] The preparation method of the high-abundance rare earth permanent magnet is as follows:

[0040] 1) Accelerated solidification: After grinding the master alloy with a good ratio, put it into the rapid solidification furnace for melting. The main parameters in the melting step are: the melting temperature is controlled at 1350 °C, the speed of the copper roll is kept at 1.2m / s during melting, and through The average thickness of the master alloy quick-setting sheet obtained by the quick-setting process is 0.3-0.5mm;

[0041] 2) Hydrogen breaking: place the obtained quick-setting sheet in a hydrogen breaking furnace, and absorb hydrogen under a hydrogen pressure of 0.2-0.25MPa; then, dehydrogenate fully at 550°C for a long time, and break the quick-setting sheet into 100-150μm Arou...

Embodiment 2

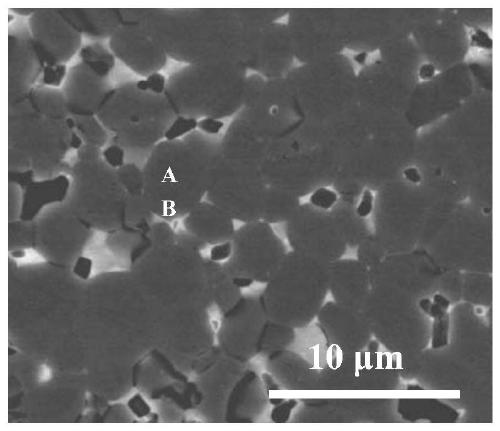

[0048] In this embodiment, the high-abundance rare earth permanent magnet is expressed in mass percent, and its nominal composition is: [Nd 0.5 (Ce 0.45 Y 0.05 )] 30.5 al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0049] The preparation method of the high-abundance rare earth permanent magnet is as follows:

[0050] 1) Accelerated solidification: After grinding the master alloy with a good ratio, put it into the rapid solidification furnace for melting. The main parameters in the melting step are: the melting temperature is controlled at 1350 °C, the speed of the copper roll is kept at 1.2m / s during melting, and through The average thickness of the master alloy quick-setting sheet obtained by the quick-setting process is 0.3-0.5mm;

[0051] 2) Hydrogen breaking: place the obtained quick-setting sheet in a hydrogen breaking furnace, and absorb hydrogen under a hydrogen pressure of 0.2-0.25MPa; then, dehydrogenate fully at 550°C for a long time, and break the quick-setting sheet into 10...

Embodiment 3

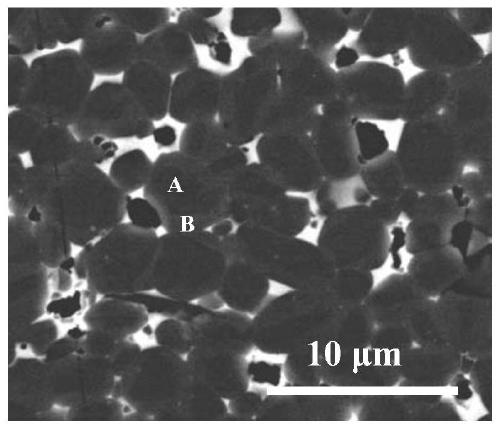

[0058] In this embodiment, the high-abundance rare earth permanent magnet is expressed in mass percent, and its nominal composition is: [Nd 0.5 (Ce 0.4 Y 0.10 )] 30.5 al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0059] The preparation method of the high-abundance rare earth permanent magnet is as follows:

[0060] 1) Accelerated solidification: After grinding the master alloy with a good ratio, put it into the rapid solidification furnace for melting. The main parameters in the melting step are: the melting temperature is controlled at 1350 °C, the speed of the copper roll is kept at 1.2m / s during melting, and through The average thickness of the master alloy quick-setting sheet obtained by the quick-setting process is 0.3-0.5mm;

[0061] 2) Hydrogen breaking: place the obtained quick-setting sheet in a hydrogen breaking furnace, and absorb hydrogen under a hydrogen pressure of 0.2-0.25MPa; then, dehydrogenate fully at 550°C for a long time, and break the quick-setting sheet into 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com