Y-contained high-abundance rare earth permanent magnet and preparation method thereof

A rare earth permanent magnet, high abundance technology, applied in magnetic objects, inductance/transformer/magnet manufacturing, magnetic materials, etc. Anisotropic field, effect of compensating for loss of coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

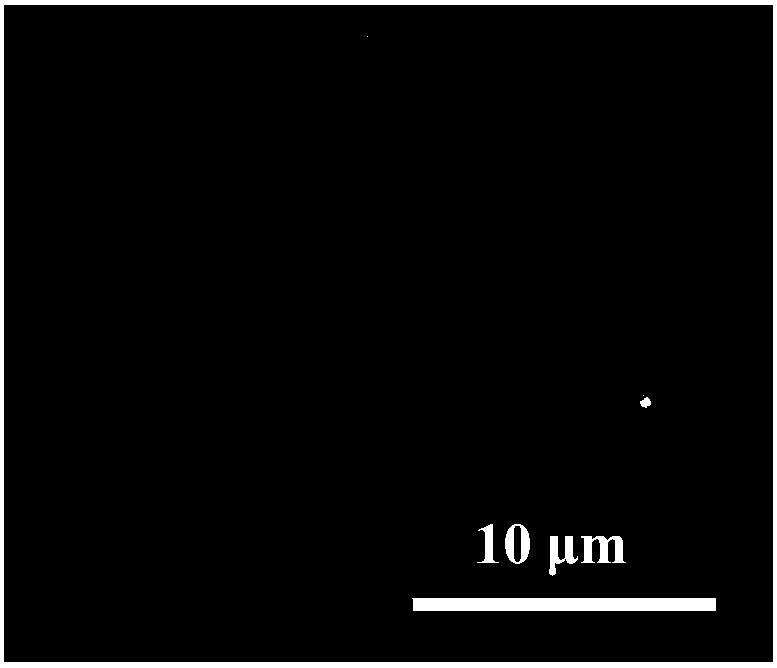

Image

Examples

Embodiment 1

[0038] In this embodiment, the high-abundance rare-earth permanent magnet is calculated in mass percent, and its nominal composition is: [Nd 0.5 Ce 0.5 ] 30.5 Al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0039] The preparation method of the high abundance rare earth permanent magnet is as follows:

[0040] 1) Quick-setting: After grinding, the well-proportioned master alloy is put into the quick-setting furnace for smelting. The main parameters in the smelting step are: the smelting temperature is controlled at 1350 ℃, and the speed of the copper roll is kept at 1.2m / s during smelting. The average thickness of the master alloy quick-setting sheet obtained by the quick-setting process is 0.3-0.5 mm;

[0041] 2) Hydrogen breaking: the obtained quick-setting sheet is placed in a hydrogen breaking furnace, and hydrogen is absorbed under a hydrogen pressure of 0.2-0.25 MPa; then, fully dehydrogenated at 550 ° C for a long time, and the quick-setting sheet is broken into 100-150 μm Alloy coa...

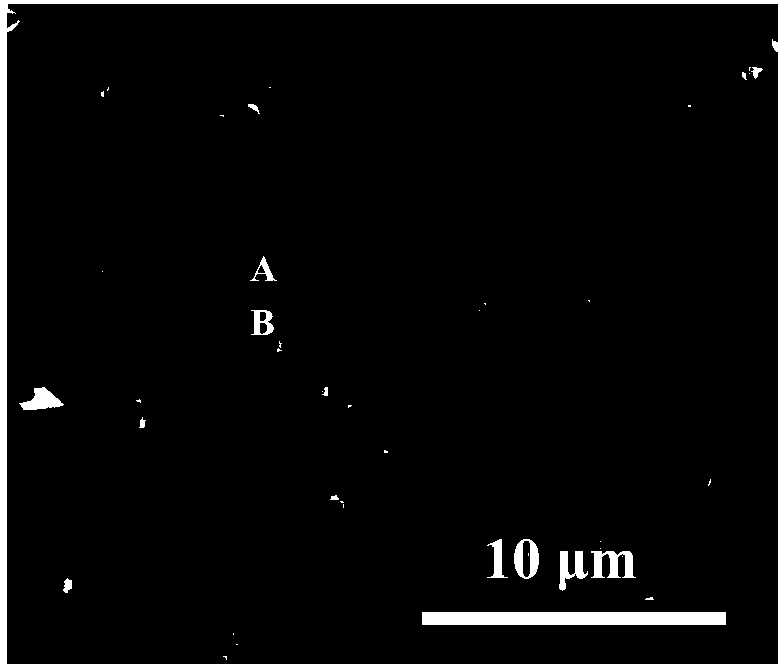

Embodiment 2

[0048] In this embodiment, the high-abundance rare-earth permanent magnet is calculated in mass percent, and its nominal composition is: [Nd 0.5 (Ce 0.45 Y 0.05 )] 30.5 Al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0049] The preparation method of the high abundance rare earth permanent magnet is as follows:

[0050] 1) Quick-setting: After grinding, the well-proportioned master alloy is put into the quick-setting furnace for smelting. The main parameters in the smelting step are: the smelting temperature is controlled at 1350 ℃, and the speed of the copper roll is kept at 1.2m / s during smelting. The average thickness of the master alloy quick-setting sheet obtained by the quick-setting process is 0.3-0.5 mm;

[0051] 2) Hydrogen breaking: the obtained quick-setting sheet is placed in a hydrogen breaking furnace, and hydrogen is absorbed under a hydrogen pressure of 0.2-0.25 MPa; then, fully dehydrogenated at 550 ° C for a long time, and the quick-setting sheet is broken into 100-150 ...

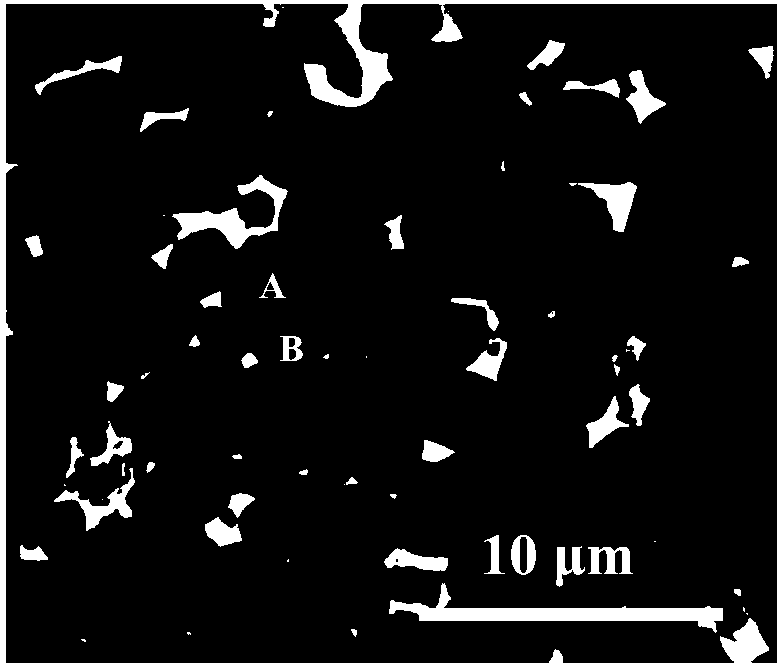

Embodiment 3

[0058] In this embodiment, the high-abundance rare-earth permanent magnet is calculated in mass percent, and its nominal composition is: [Nd 0.5 (Ce 0.4 Y 0.10 )] 30.5 Al 0.1 Cu 0.1 Fe 68.3 B 1 .

[0059] The preparation method of the high abundance rare earth permanent magnet is as follows:

[0060] 1) Quick-setting: After grinding, the well-proportioned master alloy is put into the quick-setting furnace for smelting. The main parameters in the smelting step are: the smelting temperature is controlled at 1350 ℃, and the speed of the copper roll is kept at 1.2m / s during smelting. The average thickness of the master alloy quick-setting sheet obtained by the quick-setting process is 0.3-0.5 mm;

[0061] 2) Hydrogen breaking: the obtained quick-setting sheet is placed in a hydrogen breaking furnace, and hydrogen is absorbed under a hydrogen pressure of 0.2-0.25 MPa; then, fully dehydrogenated at 550 ° C for a long time, and the quick-setting sheet is broken into 100-150 μ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com