Turning over device

A box-turning device and material box technology, which is applied in the field of casting production, can solve the problems of easy accidents, low work efficiency, and high cost of working hours, and achieve the effects of avoiding production accidents, reducing labor, and facilitating cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

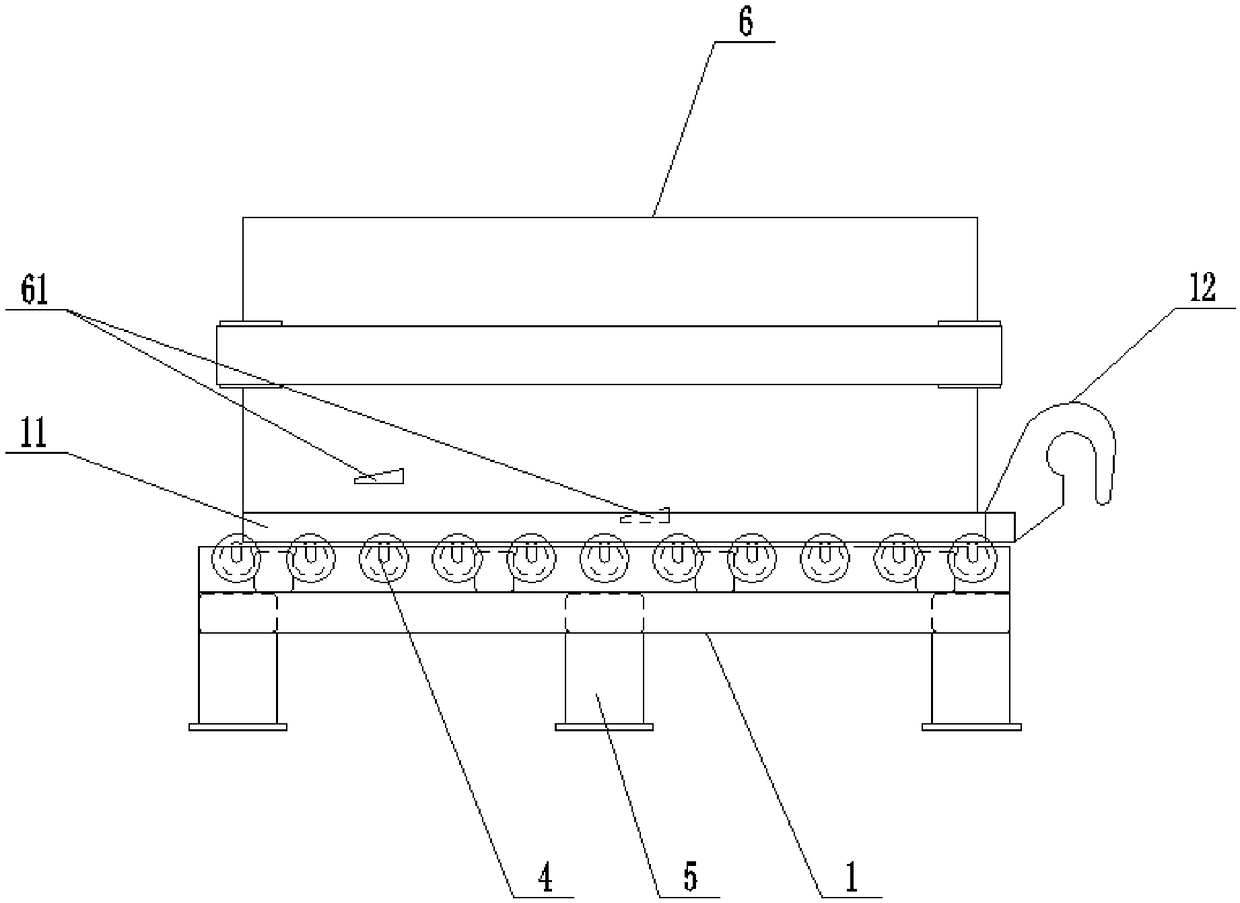

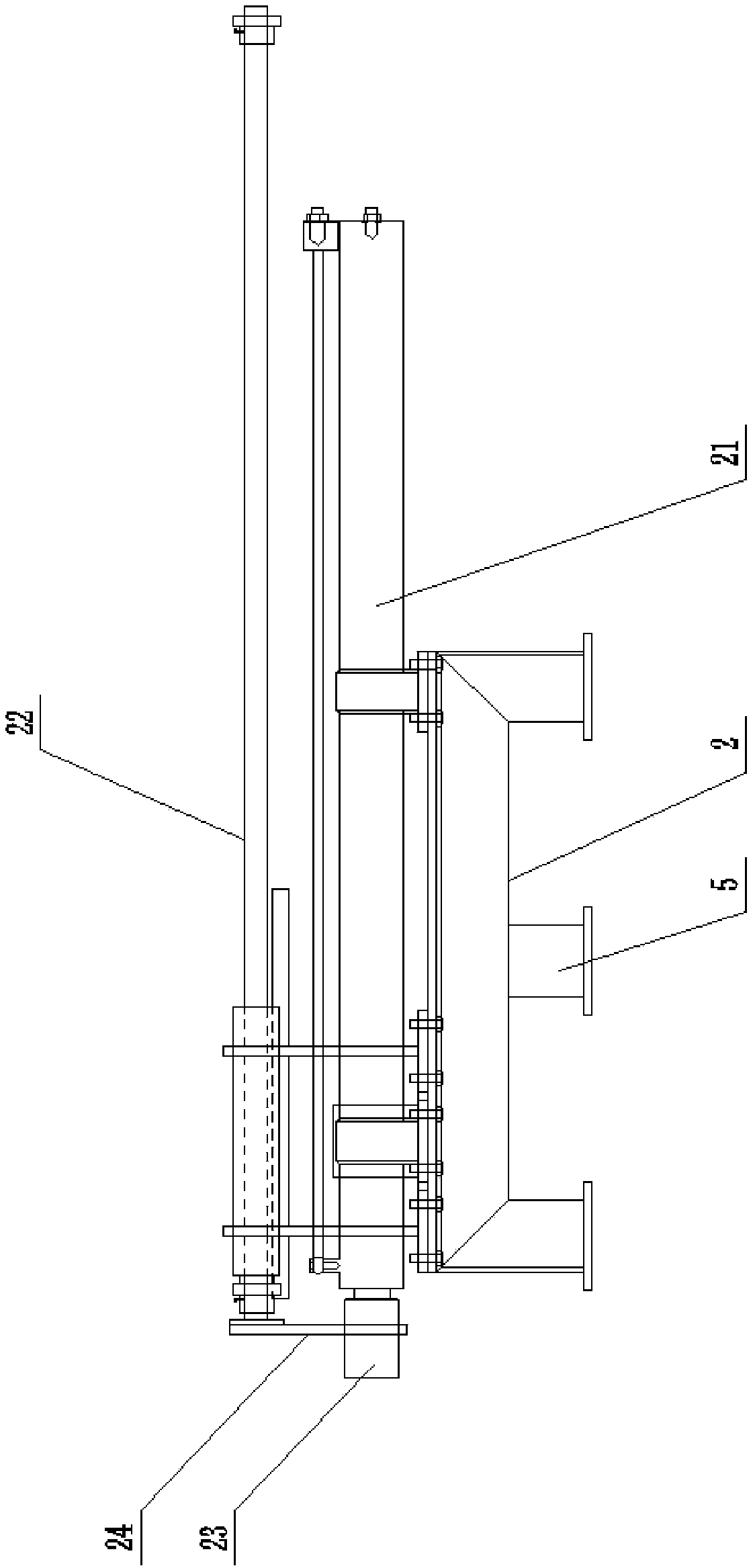

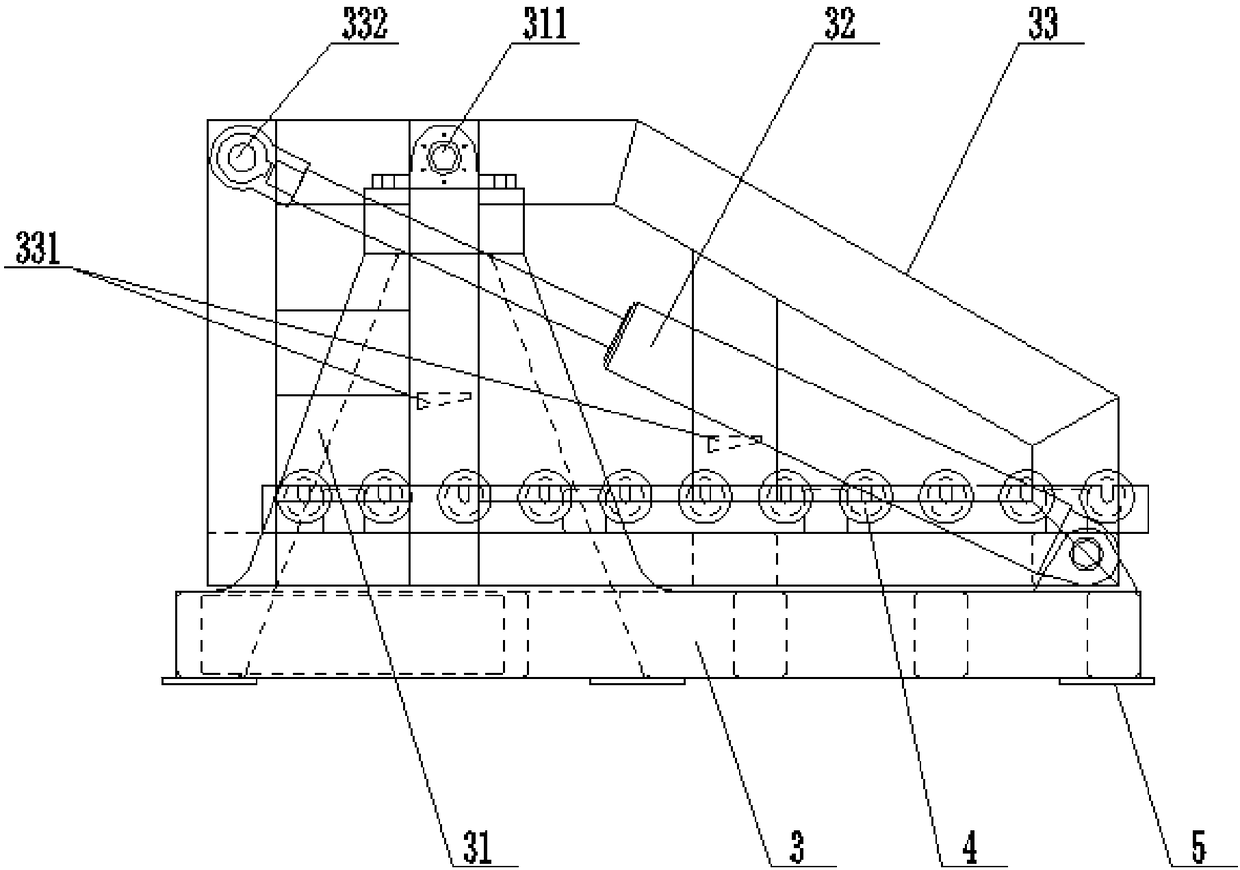

[0034] Specific embodiments of the present invention As shown in 1-7, a box turning device includes a turning mechanism 3 for turning over the material box 6 arranged on the machine base 5 in sequence; a supporting mechanism 1 for placing the material box 6 And a pushing mechanism 2 for pushing the magazine 6 from the supporting mechanism 1 to the turning mechanism 3 .

[0035] Among them, the supporting mechanism 1 is provided with a material box tray 11 that can move horizontally to the turning mechanism 3, and the material box 6 is placed on the material box tray 11 by a forklift; The first hydraulic rod 21 of 11, the material box tray 11 drives the material box 6 under the action of the first hydraulic rod 21, and then transports it to the turning mechanism 3; and the turning mechanism 3 includes a fixed bracket 31, which is fixed on the fixed bracket 31 is used to place the counterclockwise turning body 33 of the material box 6 and the second hydraulic rod 32 for pulling ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com