Q420R high-strength steel with thickness being 35-50mm for low-temperature pressure vessel and production method thereof

A Q420R, production method technology, applied in the field of medium and thick steel plate production, can solve the problems of wasting steel resources, increasing transportation costs, reducing the capacity of vehicle-mounted mobile containers, etc., achieving the effect of qualified internal flaw detection and minimized residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

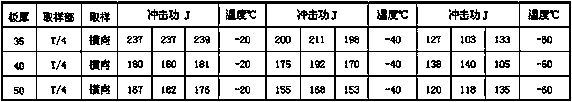

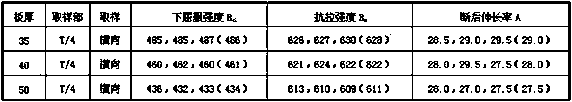

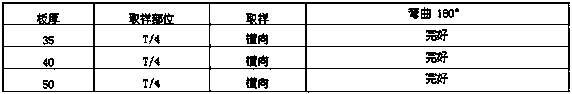

Examples

Embodiment Construction

[0020] The technical features of the present invention will be further described below in conjunction with the embodiments.

[0021] The embodiment of the present invention is to produce a kind of 35-50mm thick high-strength steel Q420R for low temperature mobile pressure vessel,

[0022] Contains the following chemical composition in mass percent (unit, wt%): C:0.13, Si:0.24, Mn:1.46, P:0.012, S:0.004, Als:0.032, V:0.056, Ti:0.003, Cr:0.220, Ni: 0.353, Nb: 0.026, CEV: 0.45, others are Fe and residual elements, through KR molten iron pretreatment, converter smelting, argon blowing treatment, LF refining, VD refining, die casting, slow cooling of steel ingots, cleaning of steel ingots, heating, A 30-50mm Q420R steel plate was obtained by controlled rolling, stack cooling, heat treatment, and slow cooling process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com