MEMS microphone and manufacturing method thereof

A technology of microelectronic machinery and manufacturing method, applied in the direction of electrostatic transducer microphone, sensor, semiconductor electrostatic transducer, etc., can solve the problem of microphone limitation, and achieve the effect of stable acoustic characteristics, easy formation, and deformation prevention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] A specific embodiment of the MEMS microphone of the present invention to achieve the above object will be described.

[0043] A first embodiment of the MEMS microphone of the present invention will be described.

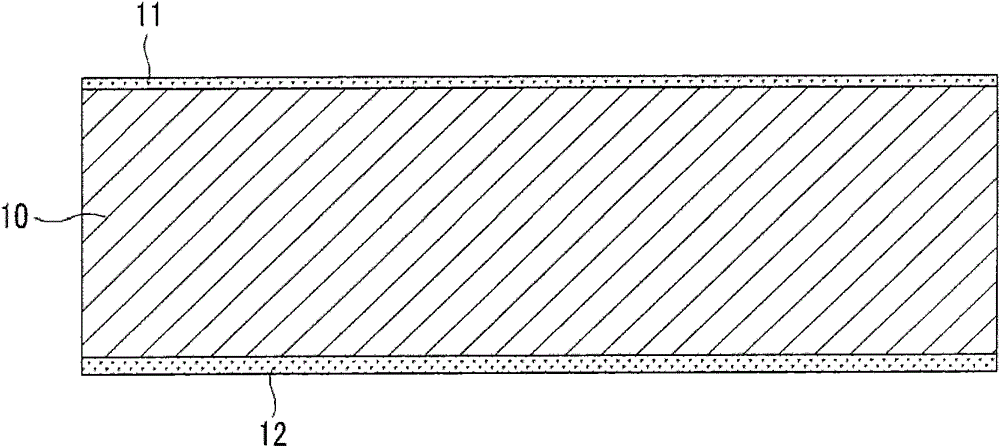

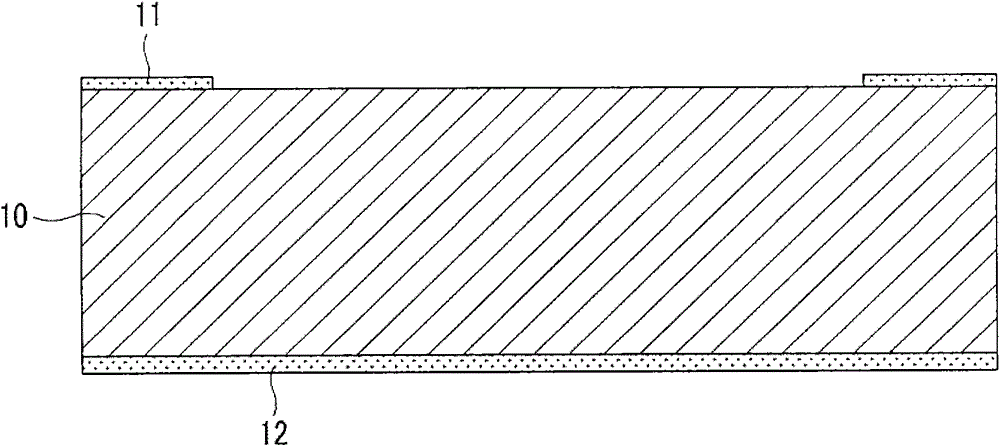

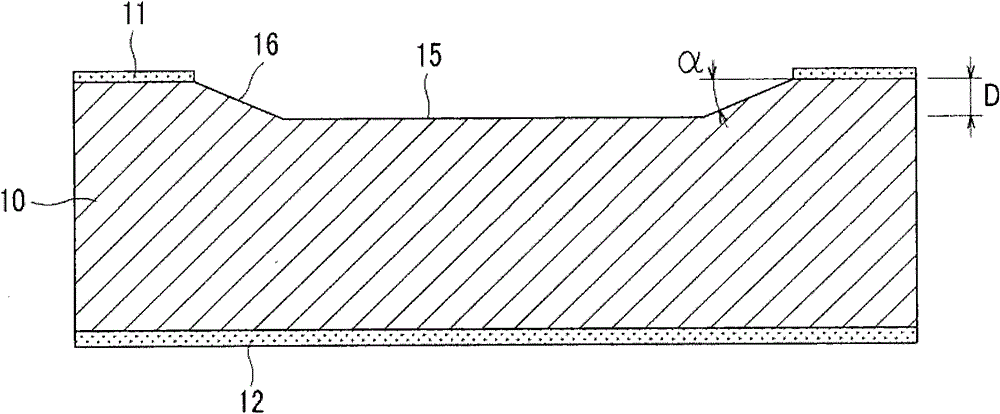

[0044] Figure 1a to Figure 1c It is a cross-sectional view showing a step of forming a void forming portion on a silicon substrate in the first embodiment of the MEMS microphone of the present invention.

[0045] refer to Figure 1a and Figure 1b , the MEMS microphone includes a silicon substrate 10 . On both sides of the silicon substrate 10, silicon nitride (Si 3 N 4 ) or silicon oxide (SiO 2) and other insulating protective layers 11, 12 (refer to Figure 1a ). At this time, the silicon nitride is vapor-deposited with protective layers 11 and 12 on the surface of the silicon substrate 10 by Low Pressure Chemical Vapor Deposition (LPCVD: Low Pressure Chemical Vapor Deposition).

[0046] The insulating protective layer 11 on the upper side of the si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com