Slipper brake of maglev train

A technology for maglev trains and brakes, which is applied in the direction of brakes interacting between brake elements and rails, railway braking systems, and railway car body components. The effect of reducing mechanical wear and reducing vertical vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are listed hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

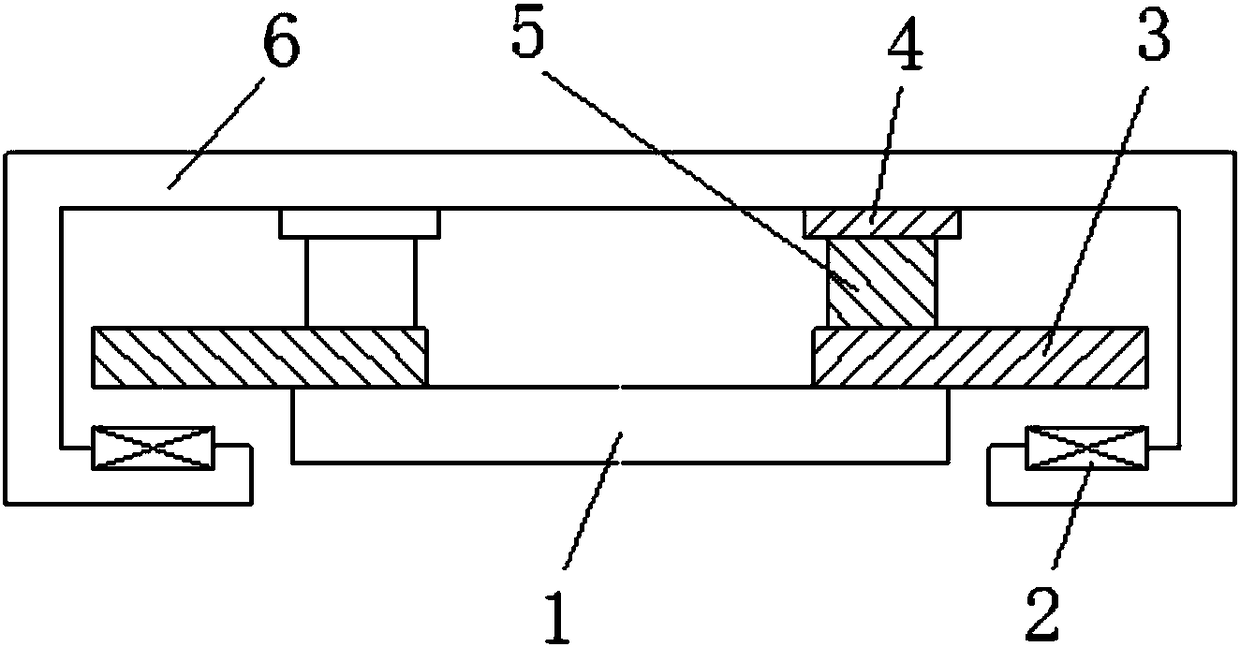

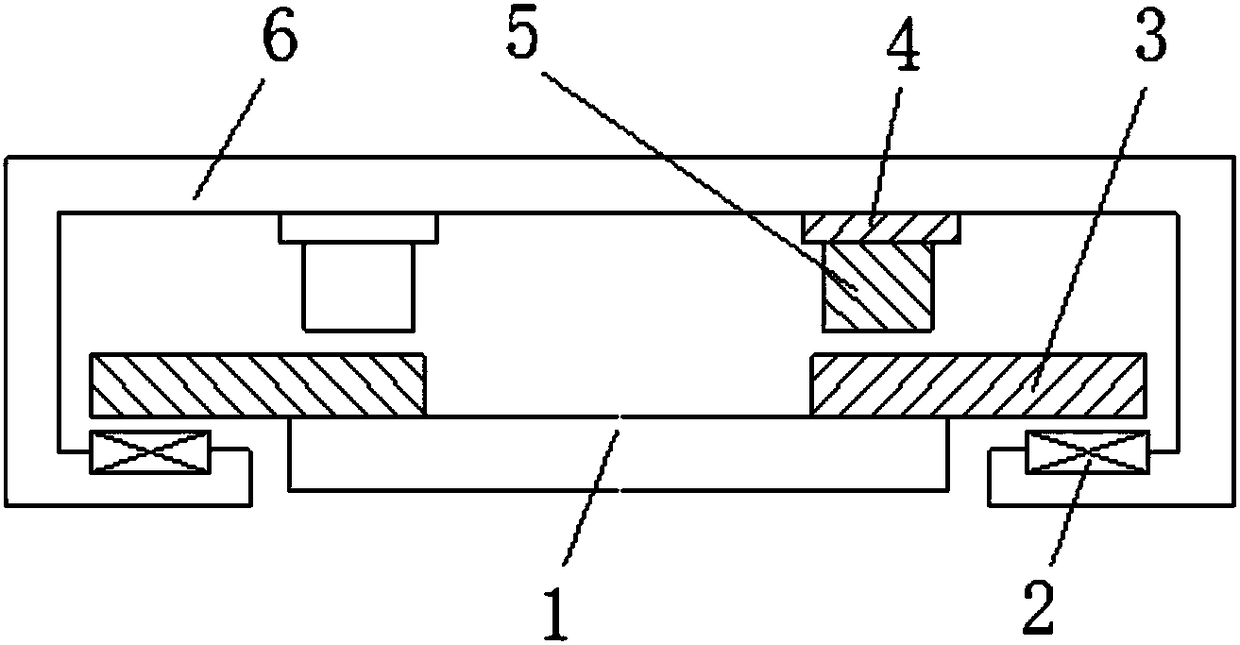

[0013] Examples such as figure 1 As shown, a sliding brake of a maglev train includes a line sleeper 1 and a suspension frame 6, both sides of the line sleeper 1 are provided with cantilevered magnetically conductive steel rails 3, the cross section of the suspension frame 6 is closed on three sides at the top and two sides, and the bottom is closed. A semi-closed structure with an opening in the middle and cantilevers on both sides, an electromagnet 2 is arranged on the upper surface of the cantilever on both sides of the bottom and is located below the far end of the magnetic steel rail 3, and the inner surface on both sides of the top of the suspension frame 6 is located on the magnetic steel rail 3. A rubber pad 4 is arranged above the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com