Speed classification system for crane balance weight oil cylinder synchronous movement and crane

A technology of synchronous motion and speed grading, applied in fluid pressure actuation system components, mechanical equipment, transportation and packaging, etc., can solve problems such as jitter, poor synchronization accuracy, start-stop shock, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

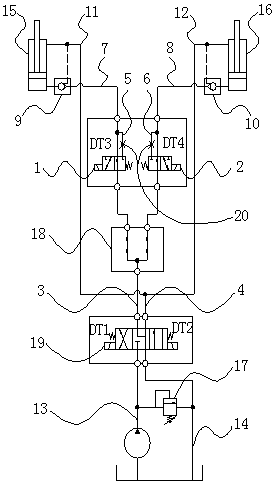

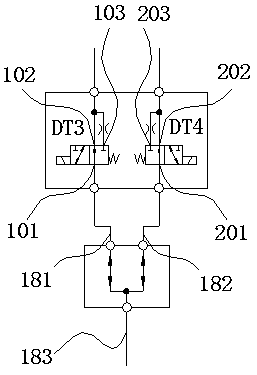

[0040] In the optional scheme of this embodiment, such as figure 1 , figure 2 As shown, this embodiment provides a speed classification system for adjusting the synchronous movement of oil cylinders, including a first reversing valve 1, a second reversing valve 2, a damper 20, a flow divider and a collection valve 18, and pressure oil The first oil port 3 and the second oil port 4 of the system circuit are established in the oil circuit and the return oil circuit. According to the expansion and contraction requirements of the actual oil cylinder, the first oil port 3 is connected to the pressure oil circuit, and the second oil port 4 is connected to the return oil circuit, then the oil cylinder can realize the extension action, switch the connection relationship, and connect the third oil port It is connected with the return oil circuit, and the second oil port is connected with the pressure oil circuit to realize the retraction action of the oil cylinder.

[0041] Further,...

Embodiment 2

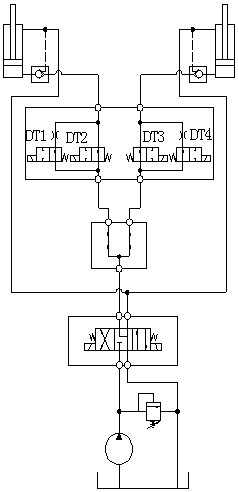

[0049] In the optional scheme of this embodiment, such as image 3 , Figure 4 As shown, this embodiment provides a speed classification system for adjusting the synchronous movement of oil cylinders. Its principle is similar to that of Solution 1, except that four two-position two-way electromagnetic reversing valves and damping are used to replace the two in Solution 1. Two-position three-way electromagnetic reversing valve 1, 2 and damping 20. During high-speed synchronous movement, keep the solenoid valve DT2\DT3 de-energized at the same time, and the solenoid valve DT1\DT4 is energized at the same time; When synchronizing, if the speed of the first oil cylinder is faster than that of the second oil cylinder, DT1 is powered off and DT2 is powered on, the first oil cylinder is in a low-speed waiting state, and at the same time, DT3 is powered off and DT4 is powered on, and the second oil cylinder is in a high-speed catch-up stage , when the two oil cylinders reach the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com