Tank car joint

A technology of tank trucks and female heads, which is applied in the direction of pipes/pipe joints/fittings, threaded connections, passing components, etc. It can solve the problems of loose handles, easy blockage of lock grooves, inconvenient unlocking, etc., to avoid loose handles and seal performance Good, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The technical solution will be described in detail below through a best embodiment, but the protection scope of the present invention is not limited to the embodiment.

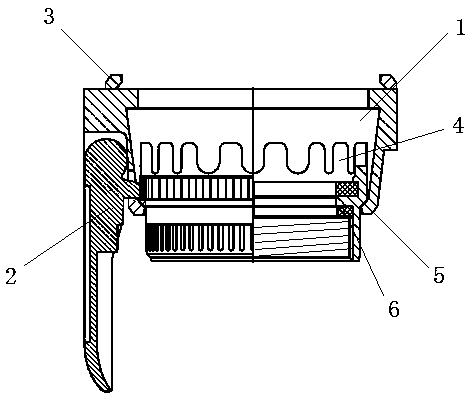

[0016] Such as figure 1 As shown, a tank car joint includes a joint body, the joint body includes a female head 1 and a handle 2, the handle 2 is movably connected to the female head 1 through bolts, and the top of the female head 1 is symmetrically arranged along the axis Claw 3, the upper end of the inner wall of the female head 1 is provided with a wave-shaped groove 4, the lower end of the inner wall of the female head 1 is provided with a thread, the lower part of the groove 4 is provided with a sealing gasket A5, and the upper end of the thread is provided with Sealing gasket B6, the sealing gasket A5 is arranged above the sealing gasket B6, there is a certain distance between the sealing gasket A5 and the sealing gasket B6, the handle 2 is an anti-vibration handle, and the handle 2 The rotatable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com