8-position strapdown inertial navigation system level calibration method based on speed observation

A system-level calibration, strapdown inertial navigation technology, applied in the field of 8-position strapdown inertial navigation system-level calibration based on velocity observation, can solve problems such as reducing calibration position scheduling, cumbersome temperature compensation process, and reducing calibration accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

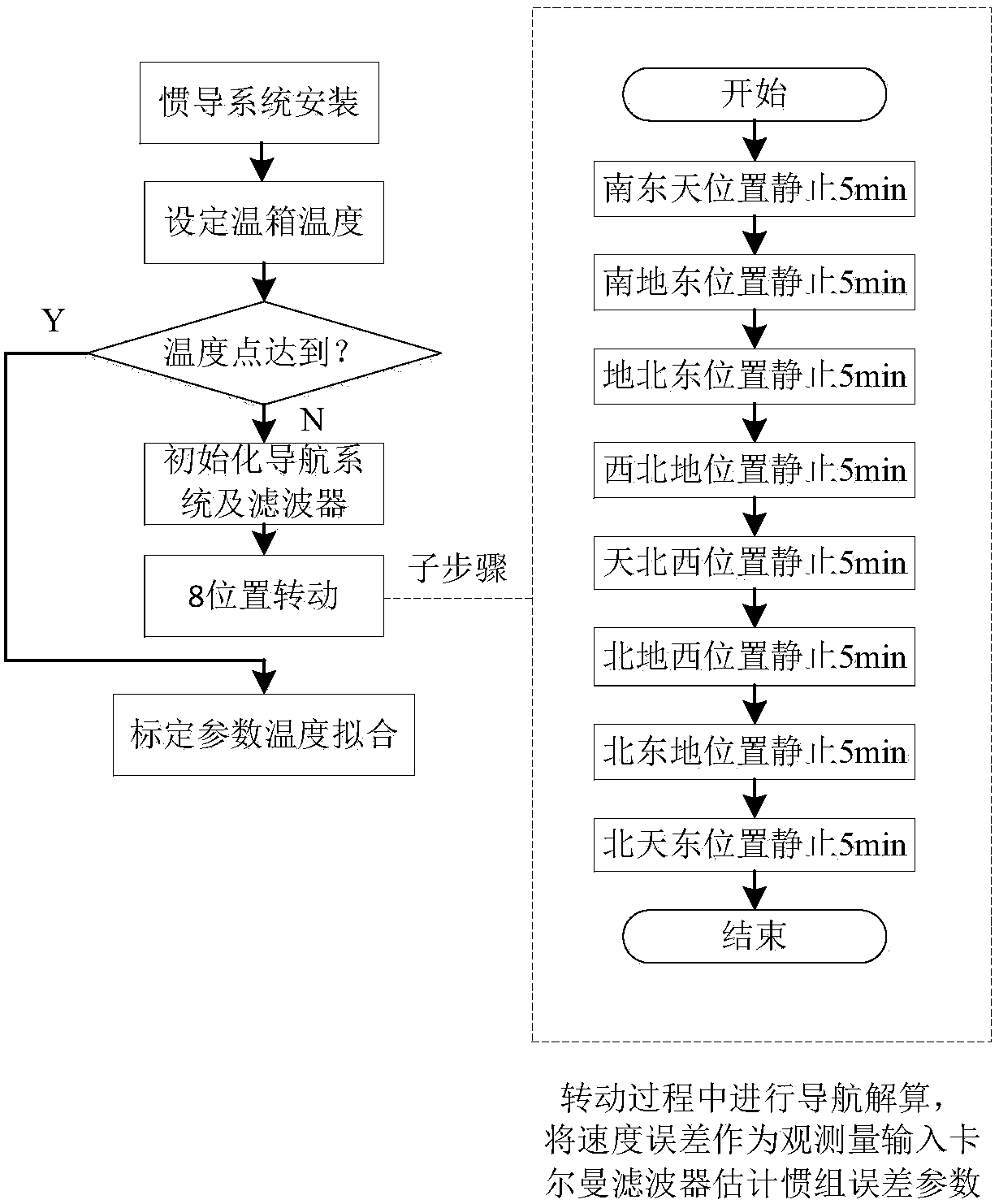

[0082] In order to describe the technical solution disclosed in the present invention in detail, further elaboration will be made below in conjunction with the accompanying drawings and specific embodiments.

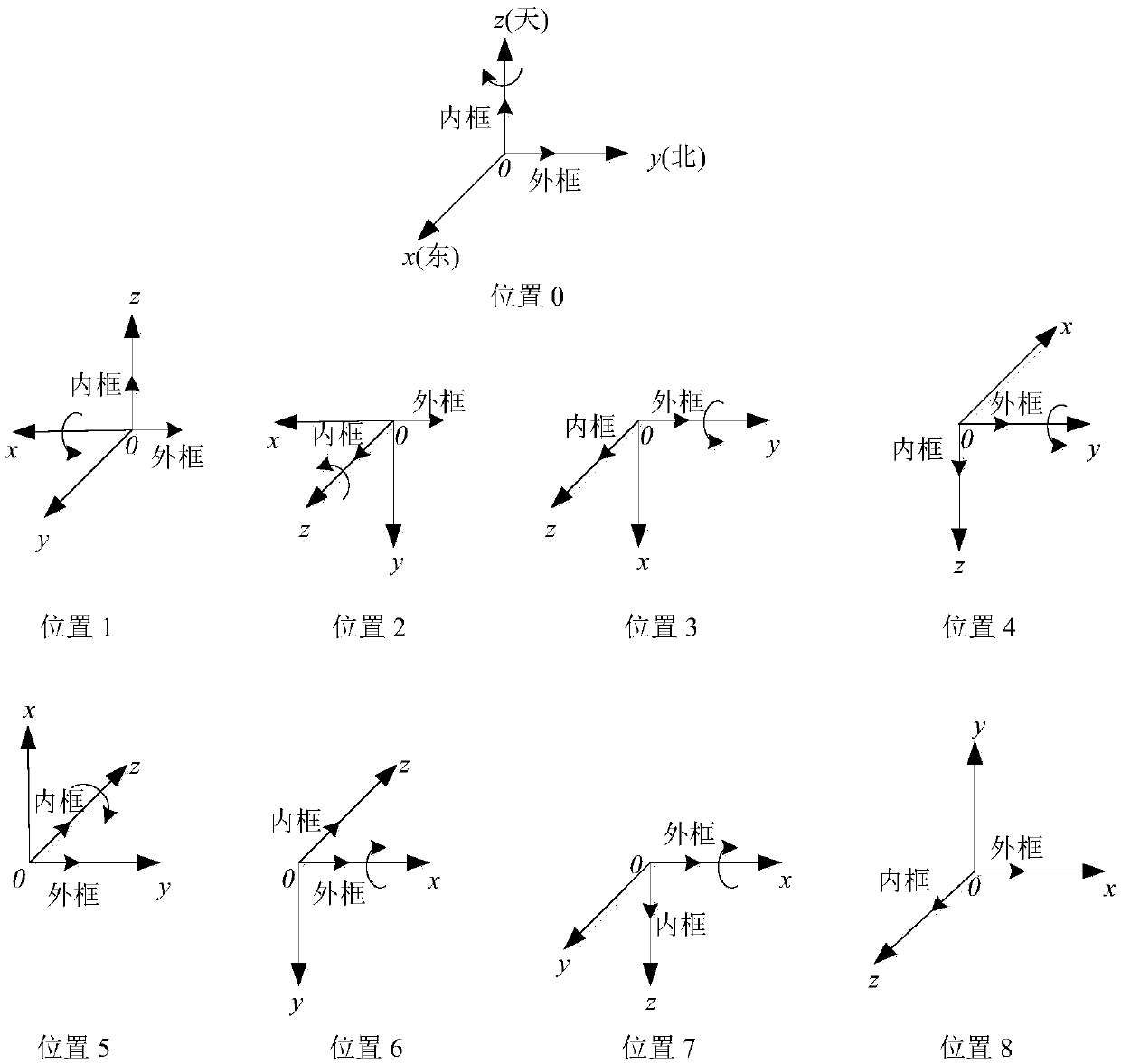

[0083] Such as figure 1 As shown, the 8-position strapdown inertial navigation system-level calibration method of a speed observation of the present invention, the specific steps are as follows:

[0084] (1) Install the strapdown inertial navigation system on a double-axis turntable with a temperature box, and determine the longitude, latitude and height of the test site;

[0085] (2) Set the temperature of the turntable thermostat to 1°C, and power on the SINS;

[0086] (3) After the system temperature is constant, initialize the strapdown inertial navigation system and the Kalman filter;

[0087] (4) Control the turntable so that the strapdown inertial navigation system rotates to the 8 positions of Nandongtian, Nandidong, Dibeidong, Xixidi, Tianbeixi, Beidixi, Beido...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com