Load sensor of multi-ring structure

A load sensor and multi-ring structure technology, which is applied in the direction of instruments, measuring devices, and force measurement, can solve the problems of high spoke sensor height, unusable load sensor, and large structural size, and achieve light weight, convenient installation, and structural The effect of high stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

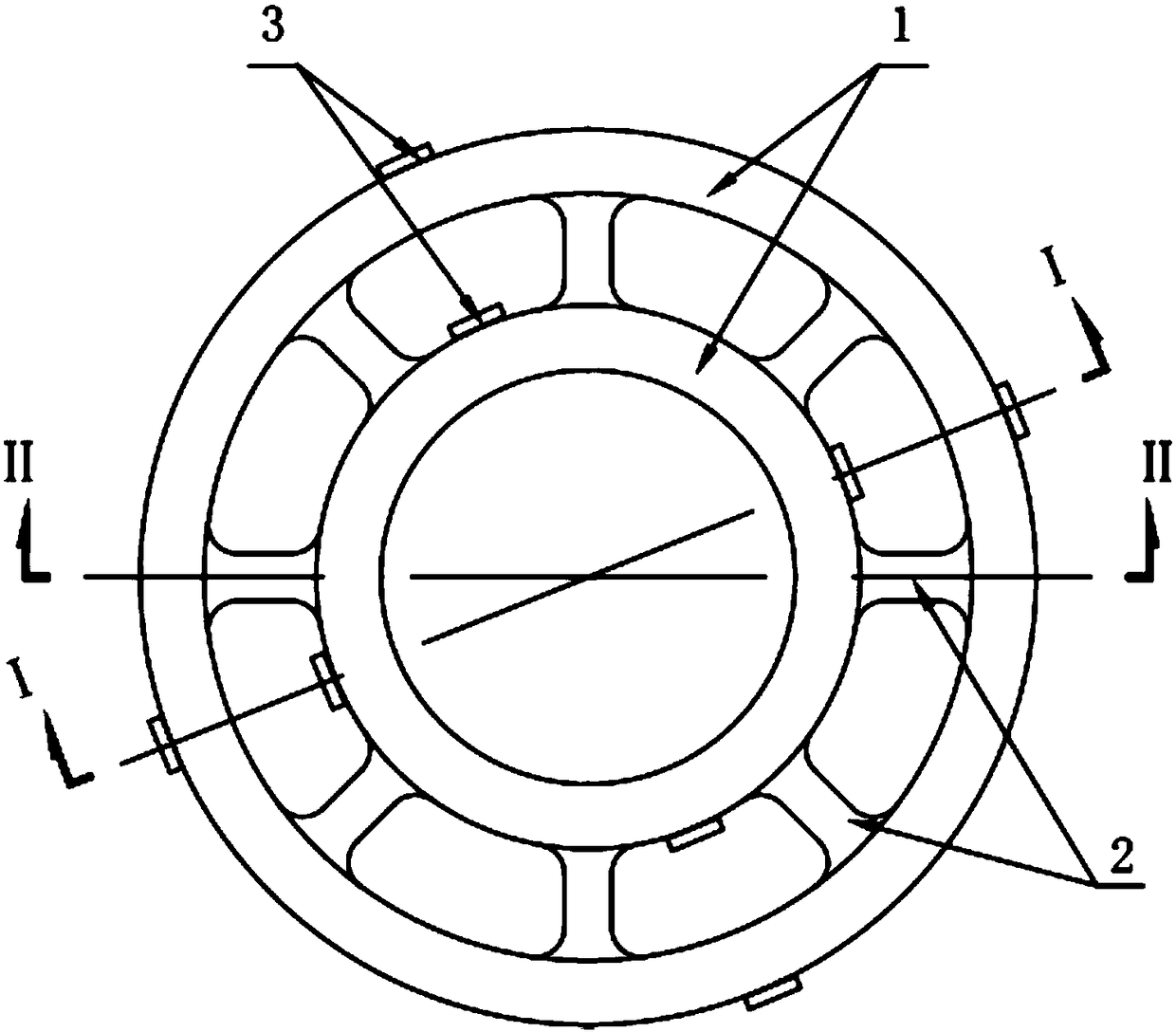

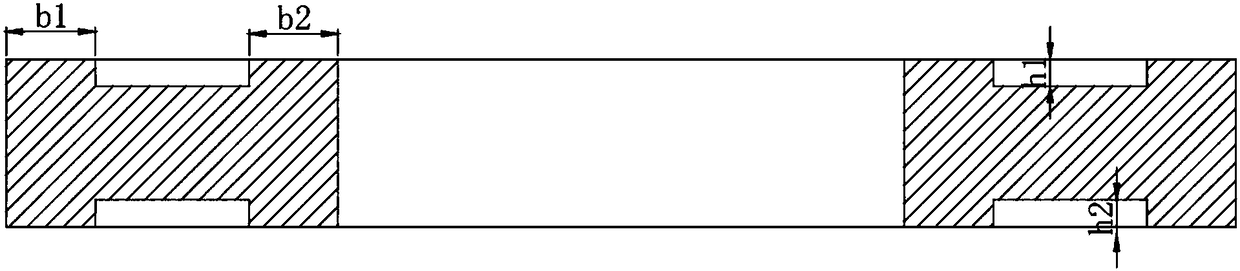

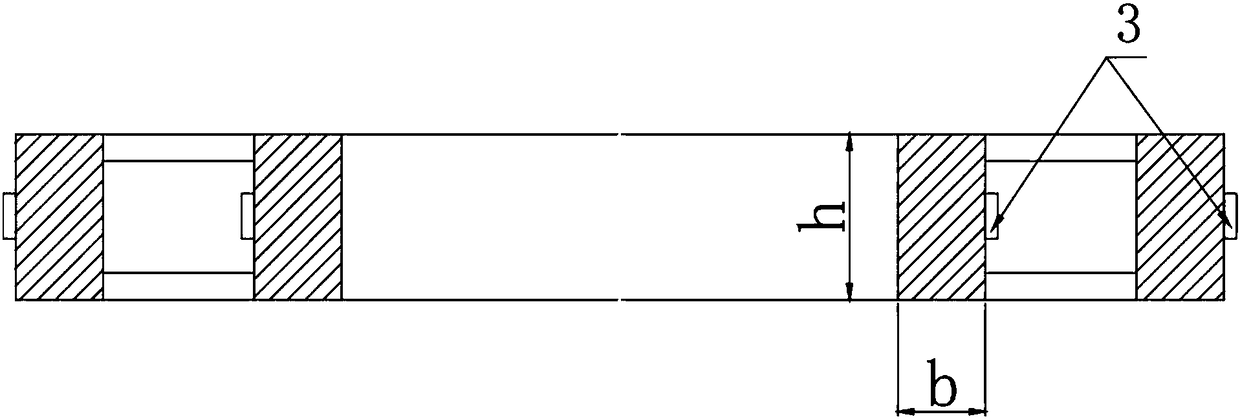

[0044] see figure 1 , figure 2 with image 3 , the multi-ring structure load sensor of Embodiment 1 of the present invention has two metal pressure-bearing rings 1 , eight spokes 2 and eight resistance strain gauges 3 .

[0045] Wherein, the metal pressure bearing ring 1 includes a first pressure bearing ring and a second pressure bearing ring.

[0046] The first pressure bearing ring is in the shape of a ring as a whole, and has a first inner peripheral surface, a first outer peripheral surface, a first upper annular surface and a first lower annular surface, and there is a gap between the first upper annular surface and the first lower annular surface. The predetermined distance h, that is, the height of the first pressure bearing ring, the first upper ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com