Transformer iron core grounding lead structure

A grounding lead, transformer technology, applied in the direction of transformer/inductor coil/winding/connection, transformer/inductor parts, electrical components, etc., can solve problems such as damage to the porcelain sleeve, high manufacturing cost, damage to the solid insulation of the transformer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

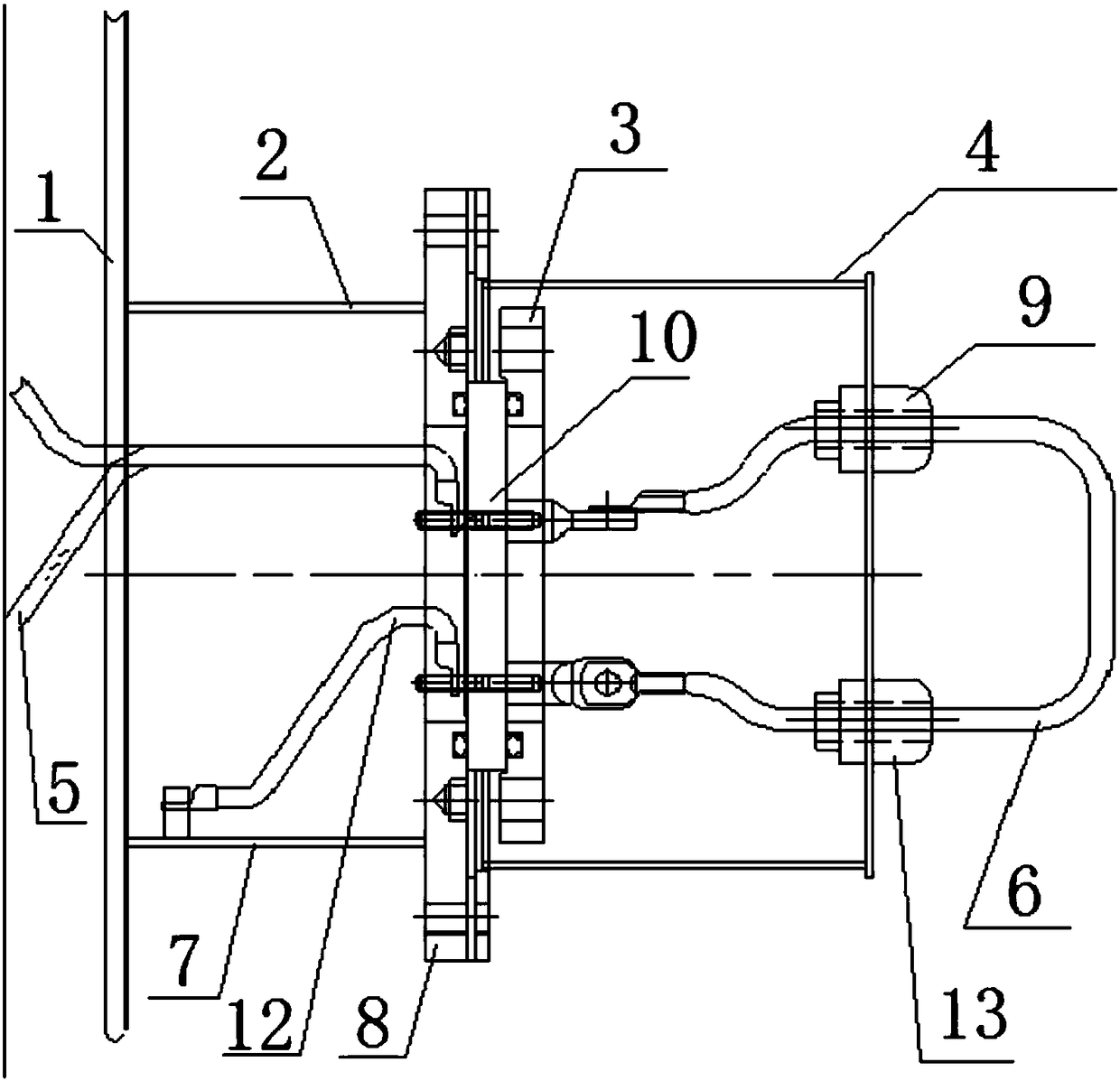

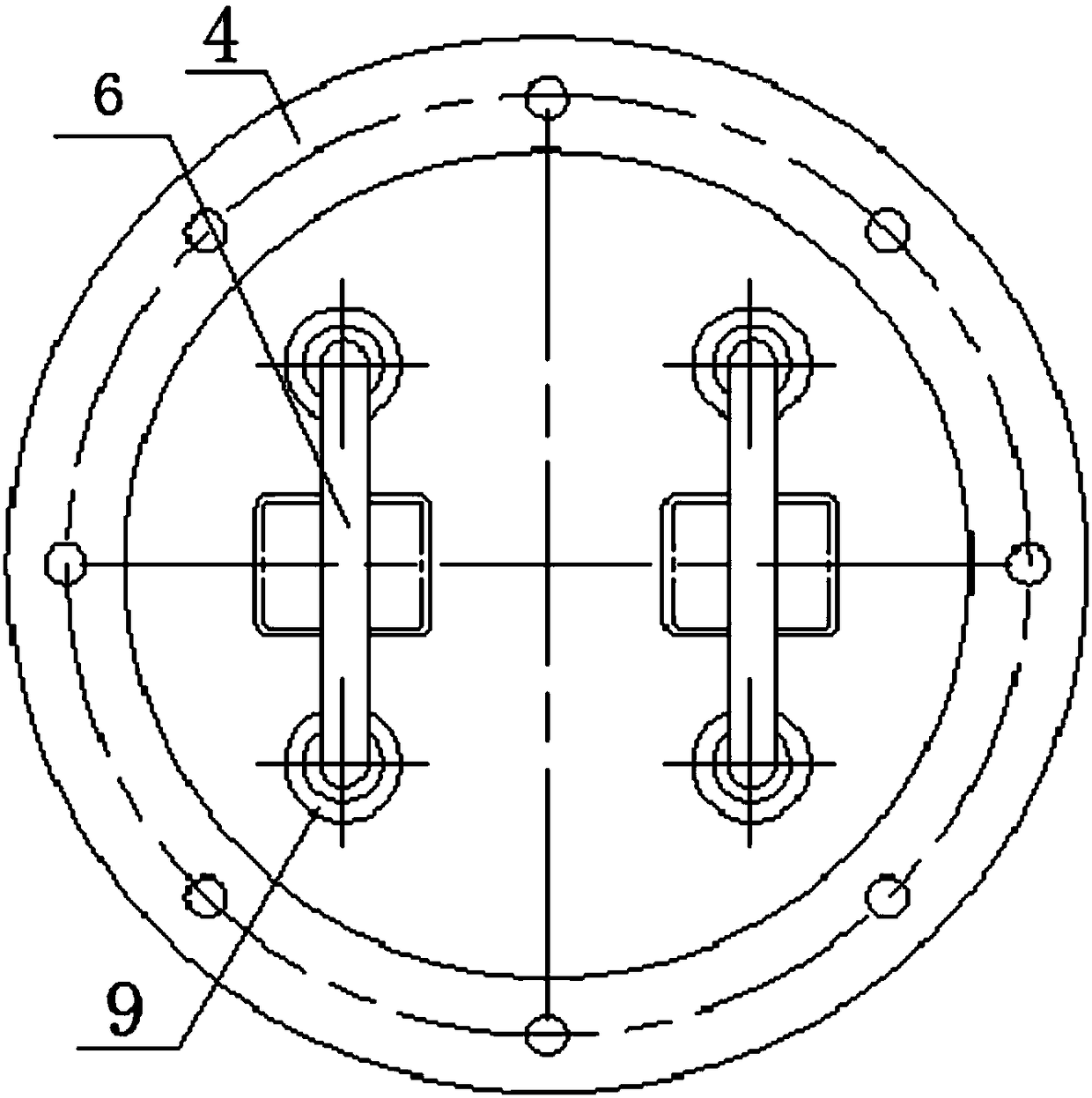

[0016] Such as Figure 1 to Figure 2 As shown, the present invention provides a transformer core grounding lead structure, including: a base 2 arranged on the transformer body 1, an insulating terminal board 10 arranged on the base 2, and an insulating terminal board 10 arranged on the base 2 and covered by the insulating terminal board 10 External shroud4. The mounting flange 3 is used to press the insulating terminal board 10. The insulating terminal board 10 is between the end cover 8 and the mounting flange 3. The insulating terminal board 10 is made by epoxy resin injection, and the terminals are directly cast on the insulating terminal board. On the plate 10, it can ensure that the seal does not leak oil.

[0017] The base 2 includes a side wall 7 connected to the transformer body 1, and an end cover 8 arranged on the side wall 7. The area of the insulating terminal plate 10 is smaller than the area of the end cover 8; several terminals are provided on the insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com