Tube clamping rack and shaping method thereof

A clamping frame and tube clamping technology, applied in the direction of antenna support/installation device, etc., can solve the problems of poor production accuracy, achieve the effect of improving accuracy, ensuring accuracy, and reducing the number of bending times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

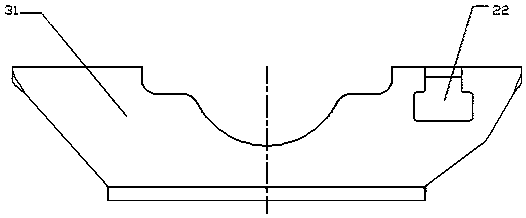

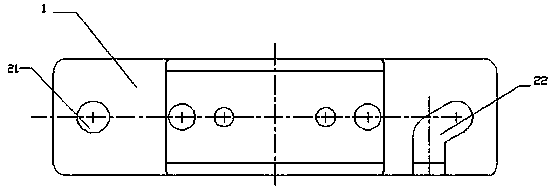

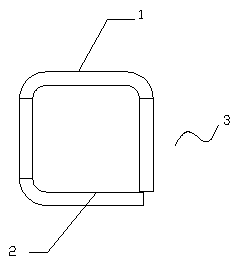

[0024] Such as Figure 1 to Figure 7 A clamping rack shown includes a clamping rack body 4; a bottom area 1, a top area 2 and a side area 3 are provided on the clamping rack body.

[0025] Two pairs of threaded connection holes 11 are symmetrically arranged on the bottom area 1 .

[0026] The side area 3 includes a front side area 31 and a rear side area 32; the front side area 31 and the rear side area 32 are in a mirror image relationship with respect to the center plane of the top area 2; the top area 2 is a rectangular hole structure; The front side area 31 and the rear side area 32 respectively extend to the side area 3 along the sides of the rectangular hole structure in the top area 2 to form a curved hole structure; the rectangular hole structure and the curved hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com