Novel weight engaging-type coupler

A gear-type, coupler technology, applied in the field of couplers, can solve the problems of no electricity, the displacement of the reed contact point, the single signal sensing function, etc., and achieve the effect of safe and reliable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

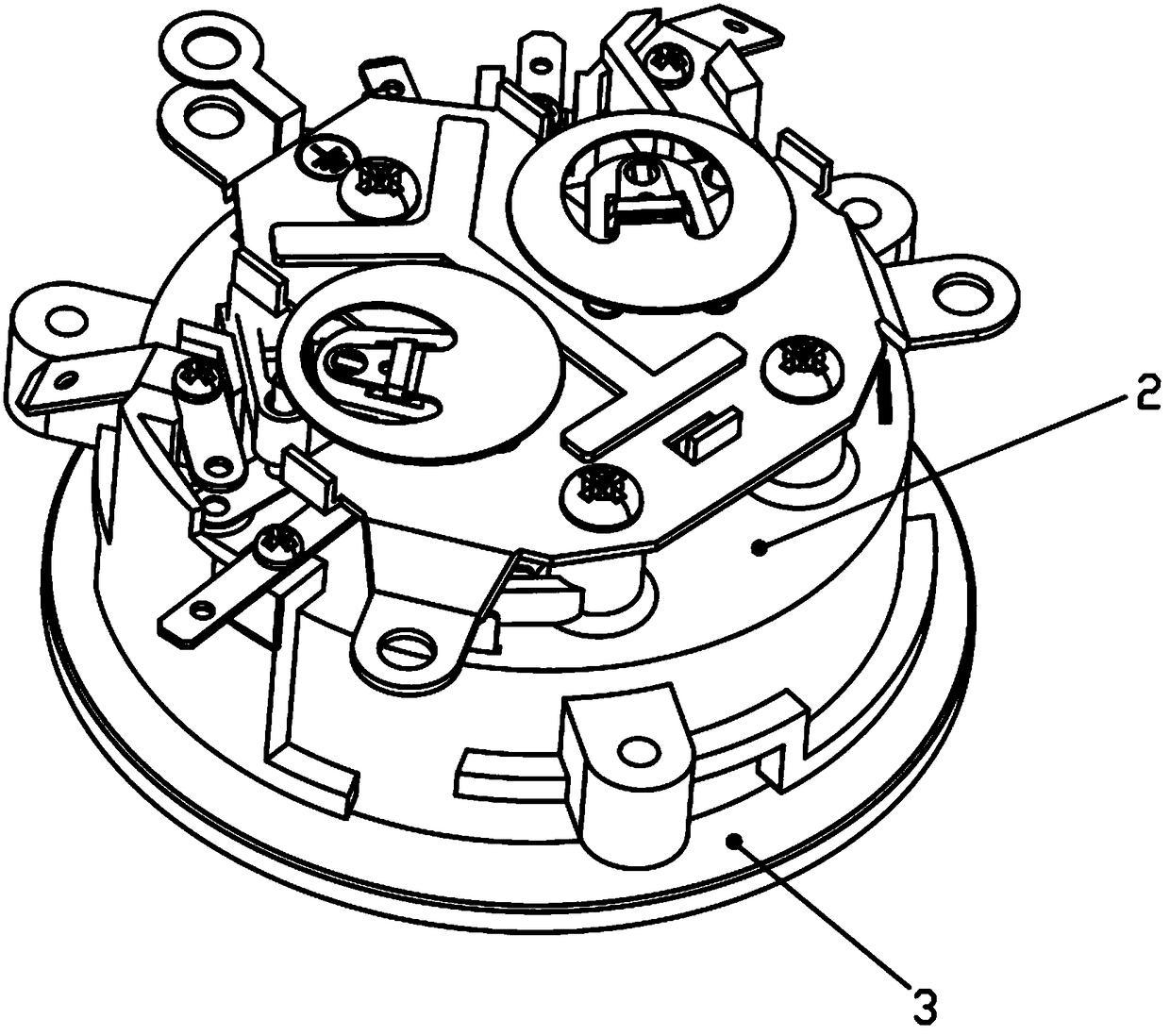

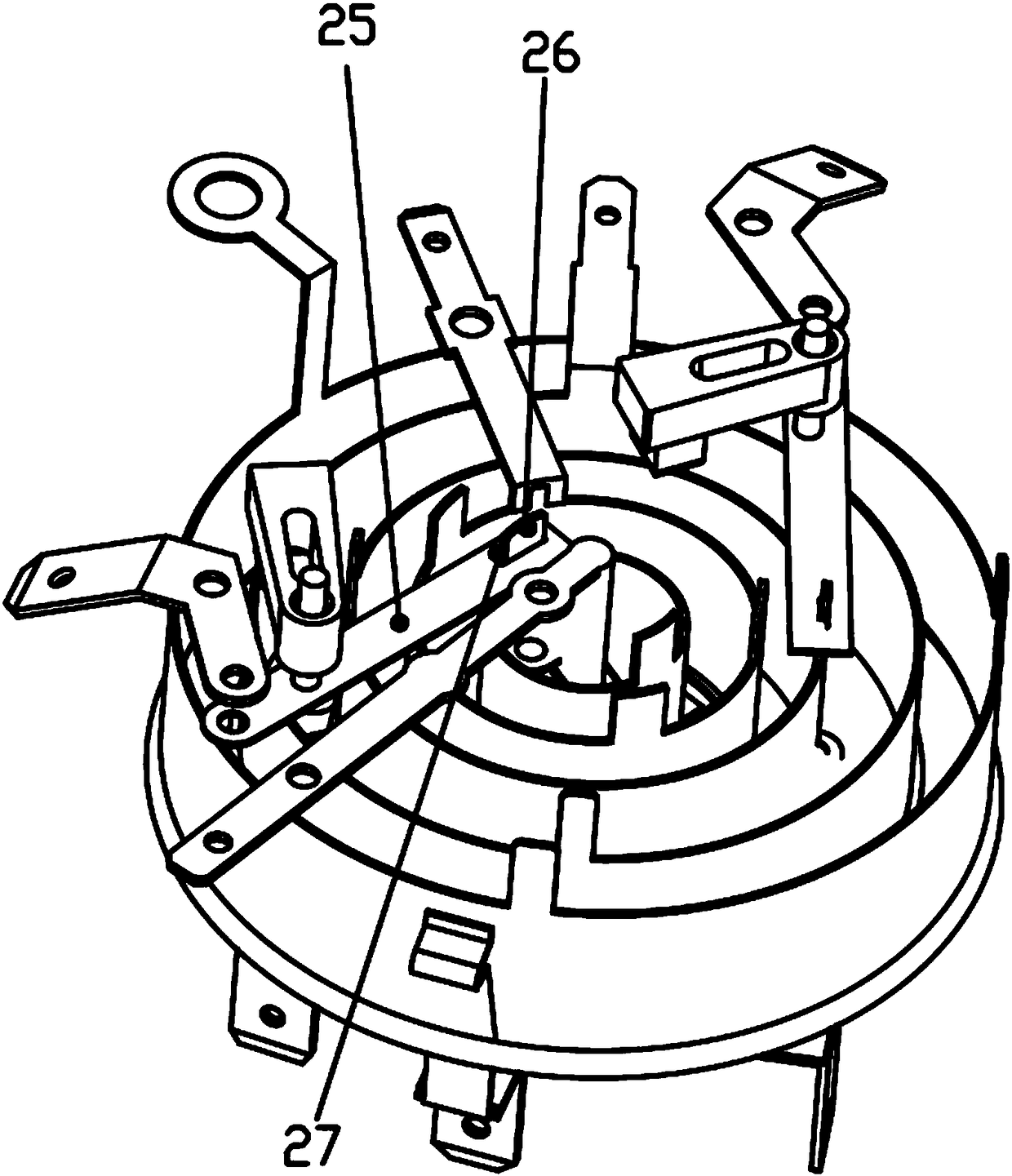

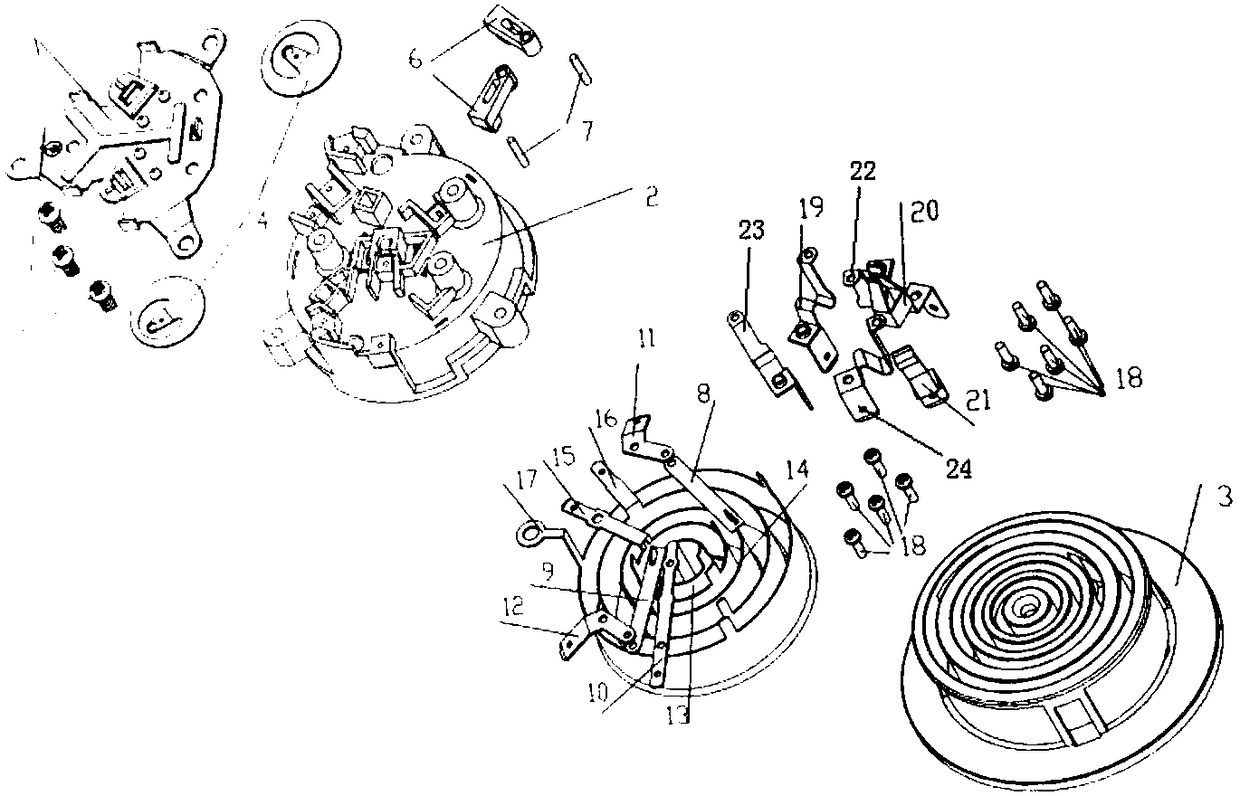

[0019] Such as Figure 1-Figure 3 As shown, the weight toothed coupler includes a connector 3 and an appliance input socket 2. The appliance input socket 2 is provided with a fixed iron plate 1, a thermal bimetal 4 and a fixing seat 6. The thermal bimetal Sheet 4, fixed iron plate 1 and appliance input socket 2 are fixedly assembled in sequence, and said appliance input socket 2 is also provided with a fixed seat 6, and said fixed seat 6 is provided with a movable hole and a porcelain rod push rod 7, and the porcelain Rod ejector rod 7 is movably matched with movable hole, and described thermal bimetal sheet 4 is mature prior art product, does not do too much elaboration here.

[0020] The appliance input socket 2 is provided with a first signal column 10, a second signal ring 15, a third signal ring 16, an N pole conductive ring 14, an L pole conductive ring 13 and a grounding ring 17. The first signal There are terminals 25 on the column 10, the second signal ring 15 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com