Assembling device and method of splined sleeve gear coupling of aircraft engine

A technology of aero-engines and gear couplings, which is applied in the direction of hand-held tools and manufacturing tools, can solve the problems of high manufacturing cost of components, low assembly efficiency, and long processing cycle, so as to shorten the assembly cycle, avoid damage, improve safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

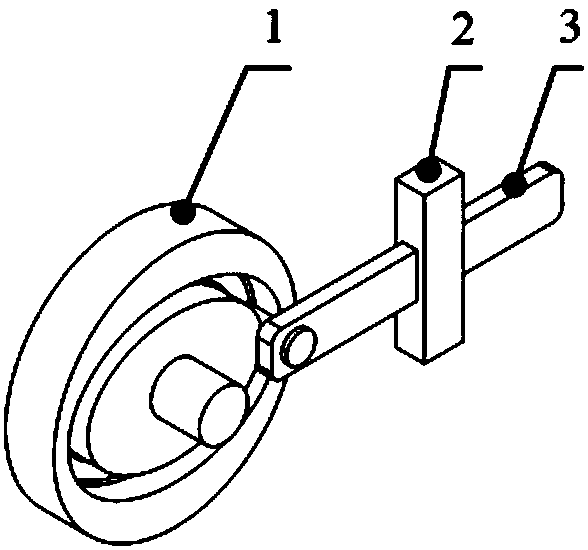

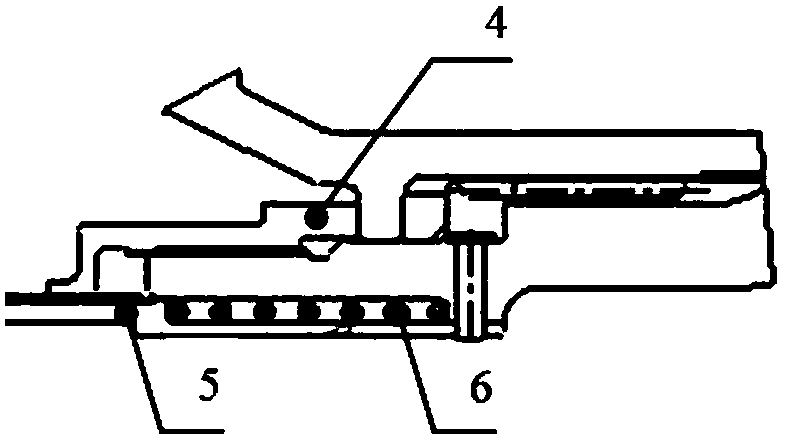

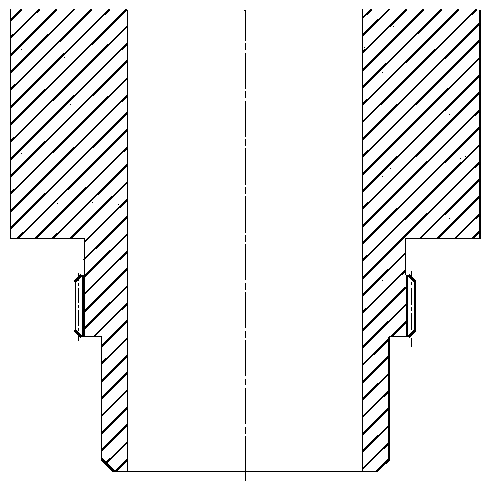

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings of the description, please refer to Figure 1~5 .

[0030] The driving component [1] is located inside the device, and its main function is to realize the telescopic movement of the bolt component [3] according to a predetermined rule, and the core part is designed in the shape of a groove.

[0031] The housing component [2] is located outside the device, and its main function is to realize the assembly and disassembly of the shaft end nut [4], and at the same time ensure that the spring [6] is in a compressed state when the device is installed on the engine, and the shaft end nut [4] and The engagement splines of the inner liner [5] are separated, and the dead bolt assembly [3] can be freely expanded and contracted. The housing assembly has a guide hole for controlling the direction of the deadbolt assembly [3]. The housing assembly [2] has external splines t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com