Patents

Literature

33results about How to "Structure diagram" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

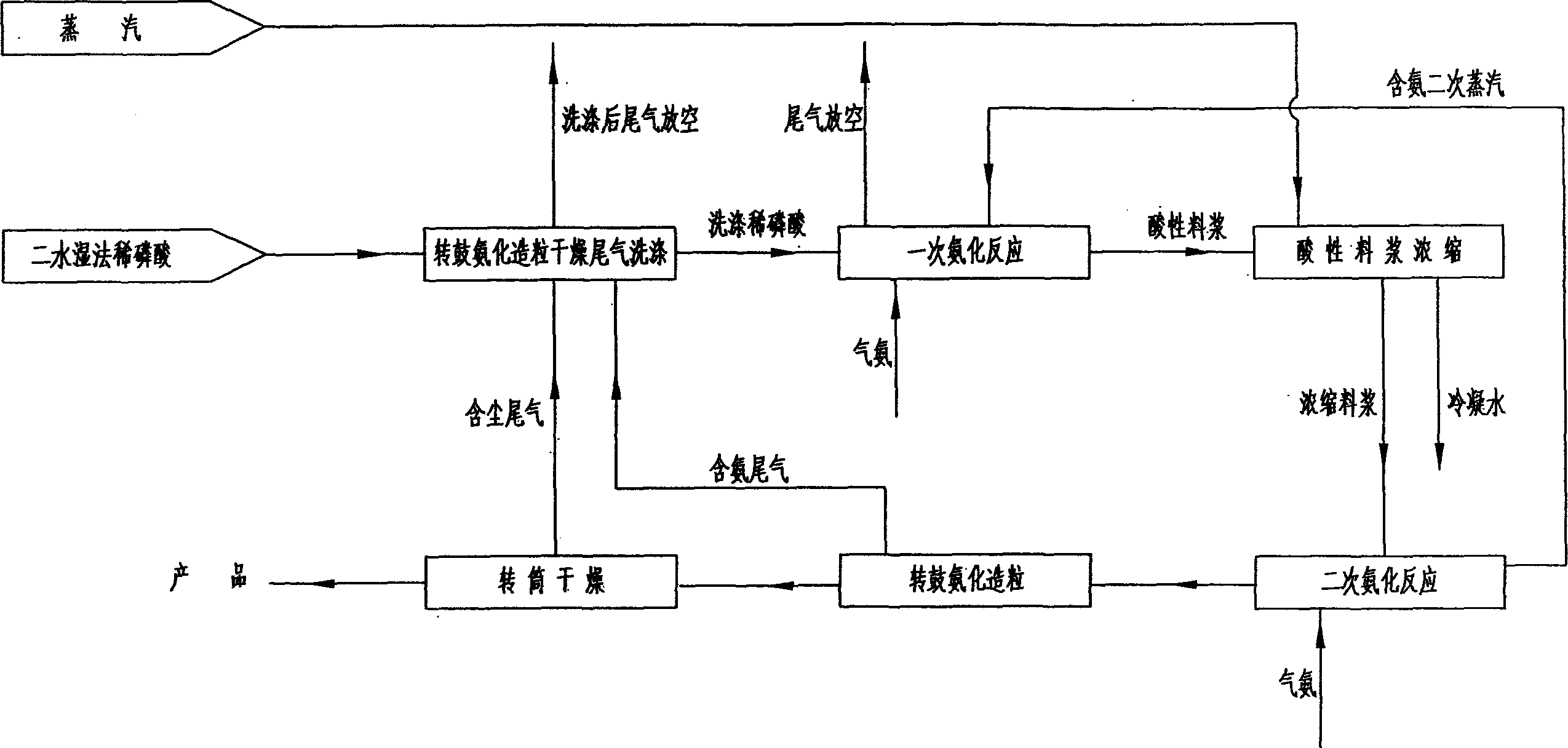

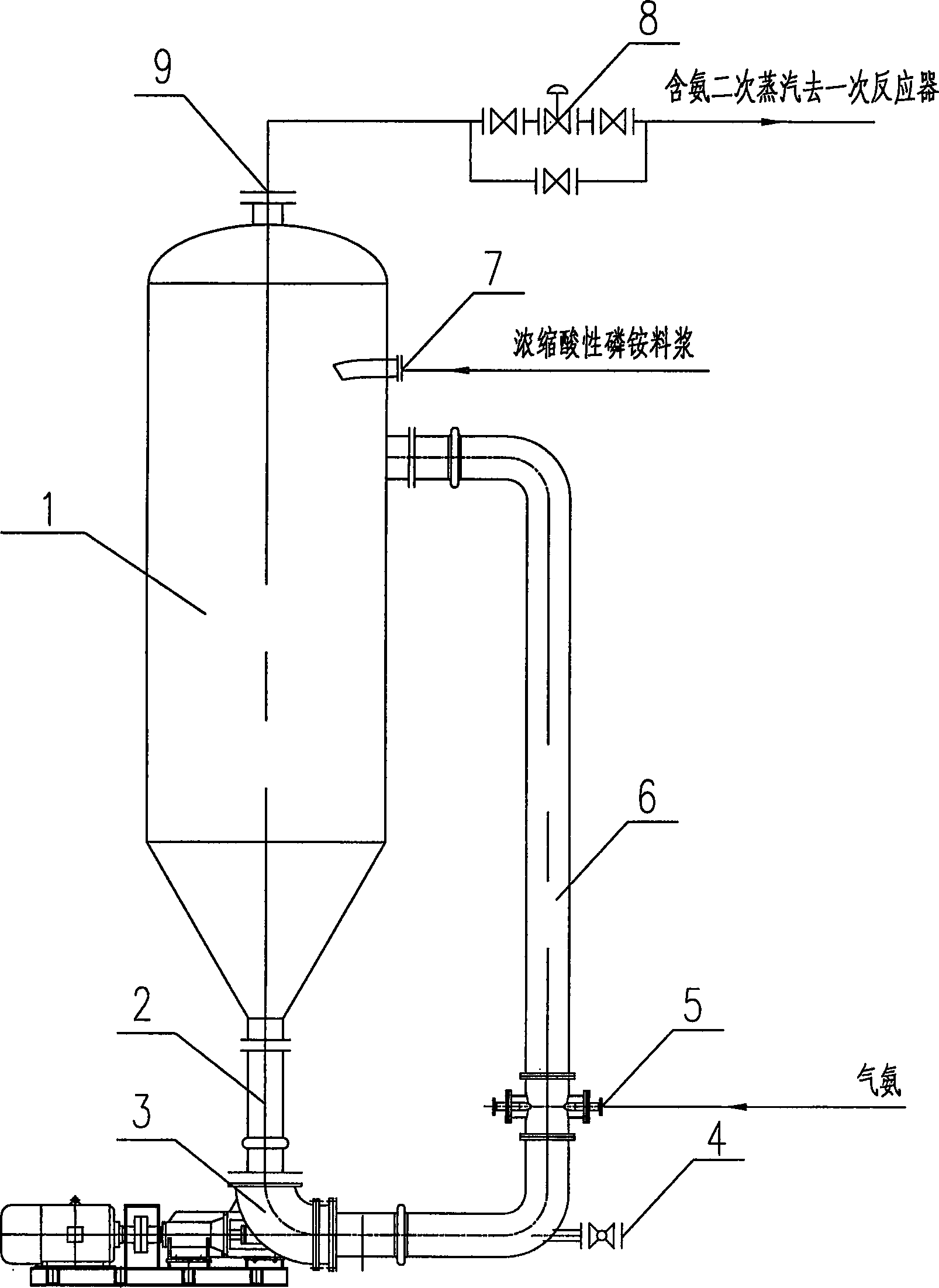

Method for producing diammonium phosphate by concentrating acid slime, and secondary ammoniation reactor

InactiveCN1872669AGood characterIncrease concentrationPhosphatesAlkali orthophosphate fertiliserDiammonium phosphatePhosphoric acid

This invention discloses a method for producing di-ammonium phosphate by concentration of acidic slurry. The method comprises: (1) performing a first ammonification on diluted phosphoric acid to obtain an acidic slurry of ammonium dihydrogen phosphate; (2) concentrating so that the water content is 13-20%; (3) performing a second ammonification so that the neutralization degree is increased to 1.30-1.50; (4) performing further ammonification so that the neutralization degree reaches 1.60-1.90; (5) granulating and controlling the water content at 2-4%. The mol. ratio of P to N in ammonium dihydrogen phosphate is 0.32-0.40.

Owner:四川川大中德环保技术有限公司

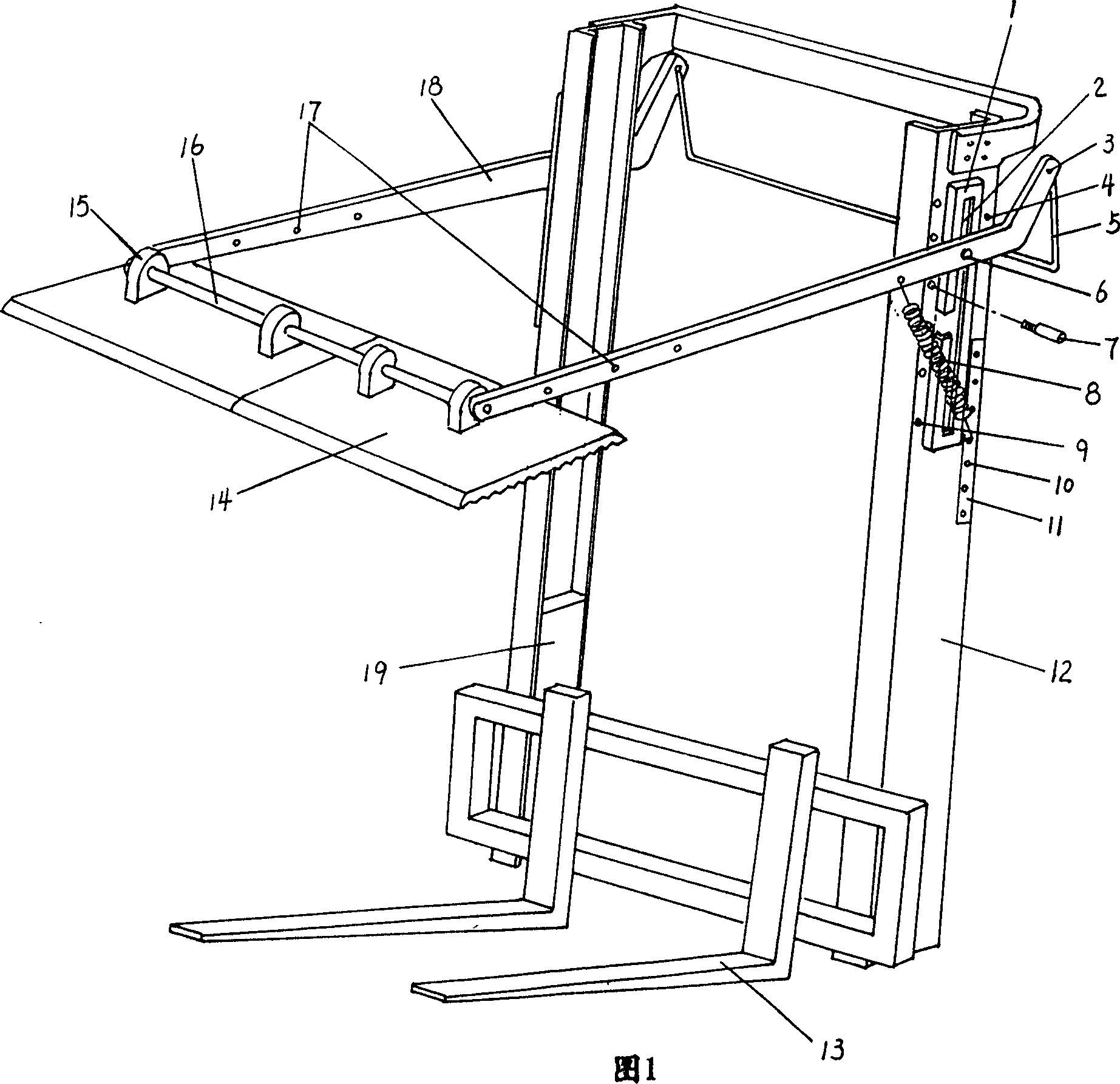

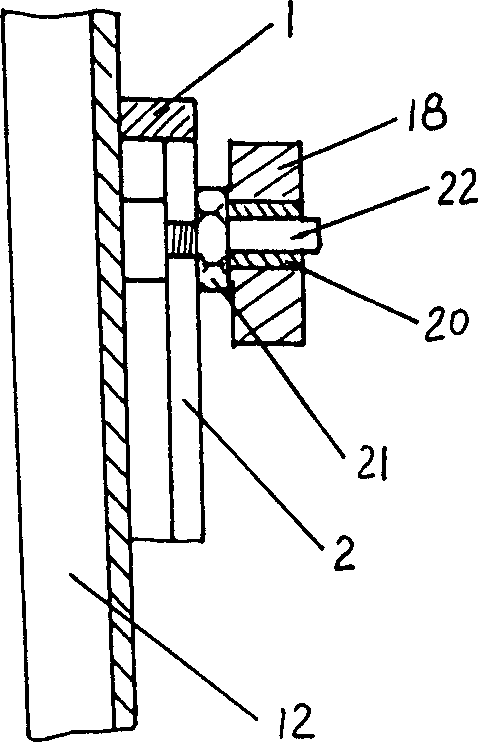

Equipment in use for fork truck anti drifting-down freight

A good dropping preventor for fork lifter is composed of a pair of press arm connecting plates fixed to both sides of gantry, a pair of press arms pivoted to said connecting plates, a pull handle pivoted to the ends of said press arms, a press plate connected to front ends of said press arms, a pair of tension springs connected between press arm and gantry, and a pair of stop pins.

Owner:彭雪峰

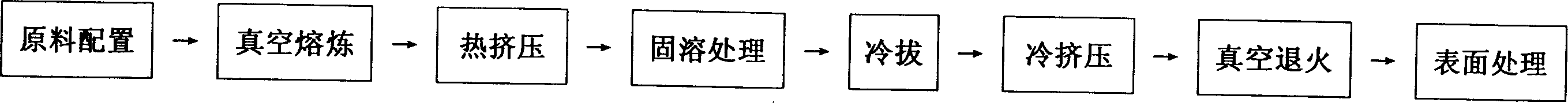

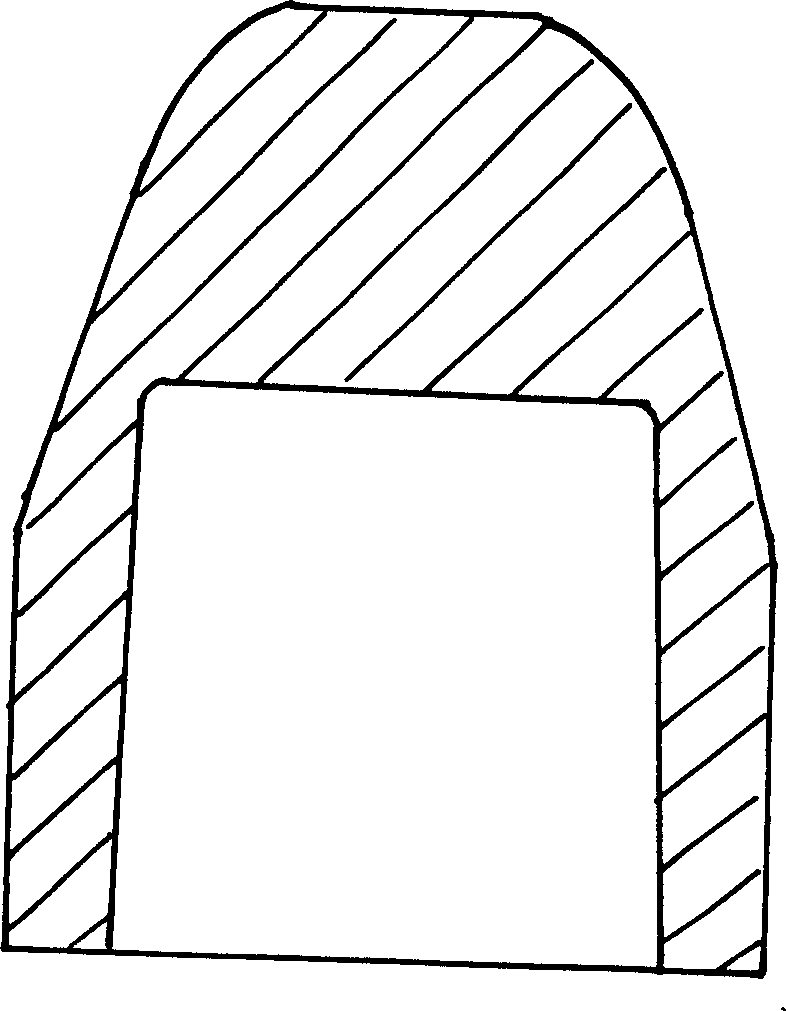

Manufacturing method of electrode cap used for welding automobile coated steel plate

InactiveCN1597223AAvoid alloying tendencyMeet the requirement of no sticking weldingElectrode featuresWelding/cutting auxillary devicesSolution treatmentSheet steel

A technology for preparing the high-performance electrode cap for welding the coated steel palte of car includes such steps as proportional mixing cathode copper, Cr powder Zr powder and Mg powder, smelting in vacuum furnace, pouring in circular mould, cleaning the surface of ingot, hot squeeznig to become rod, solutionizing, cold drawing, blanking, cold die pressing, vacuum annealing, trimming and polishing.

Owner:中外合资常熟明辉焊接器材有限公司

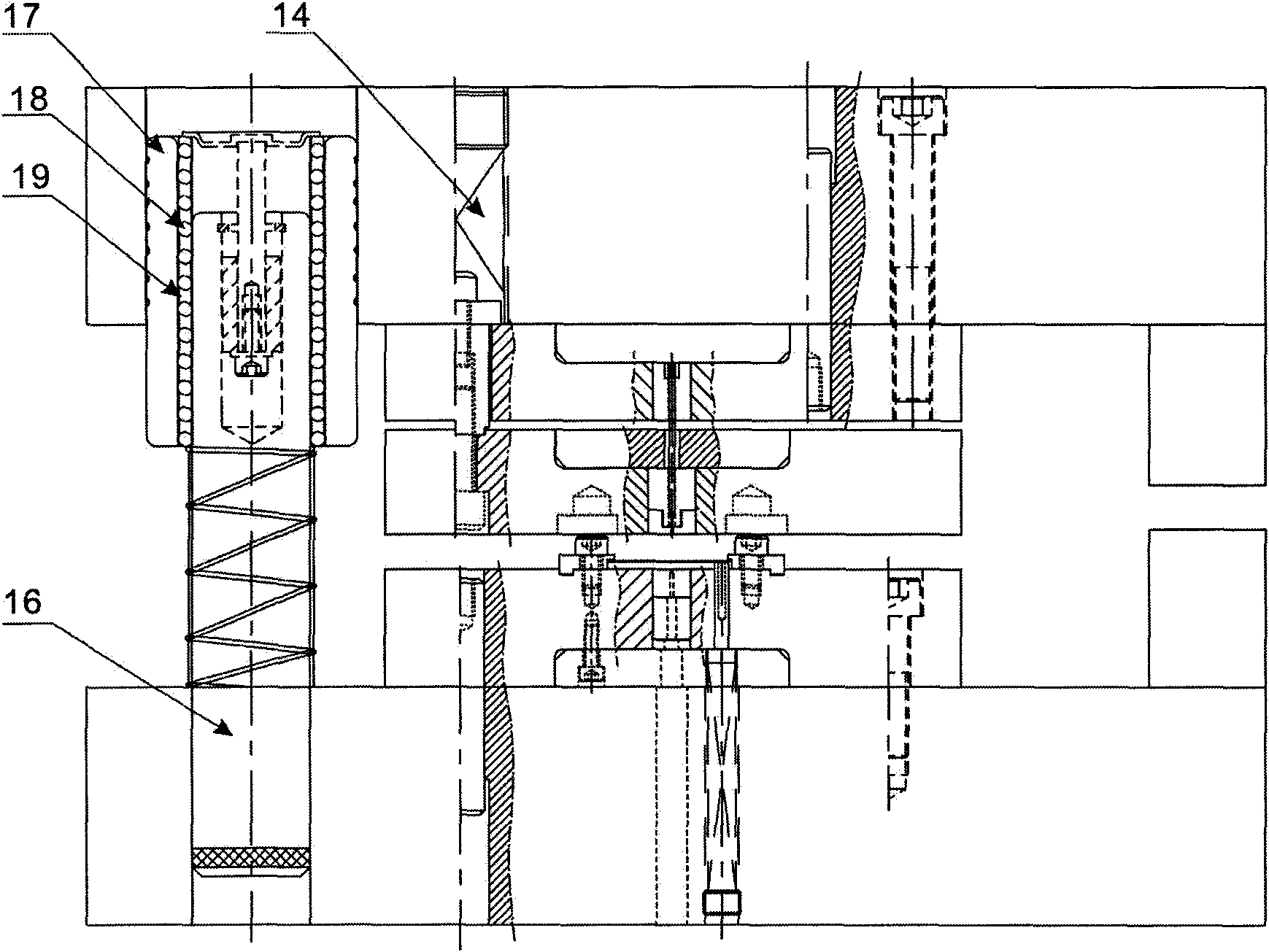

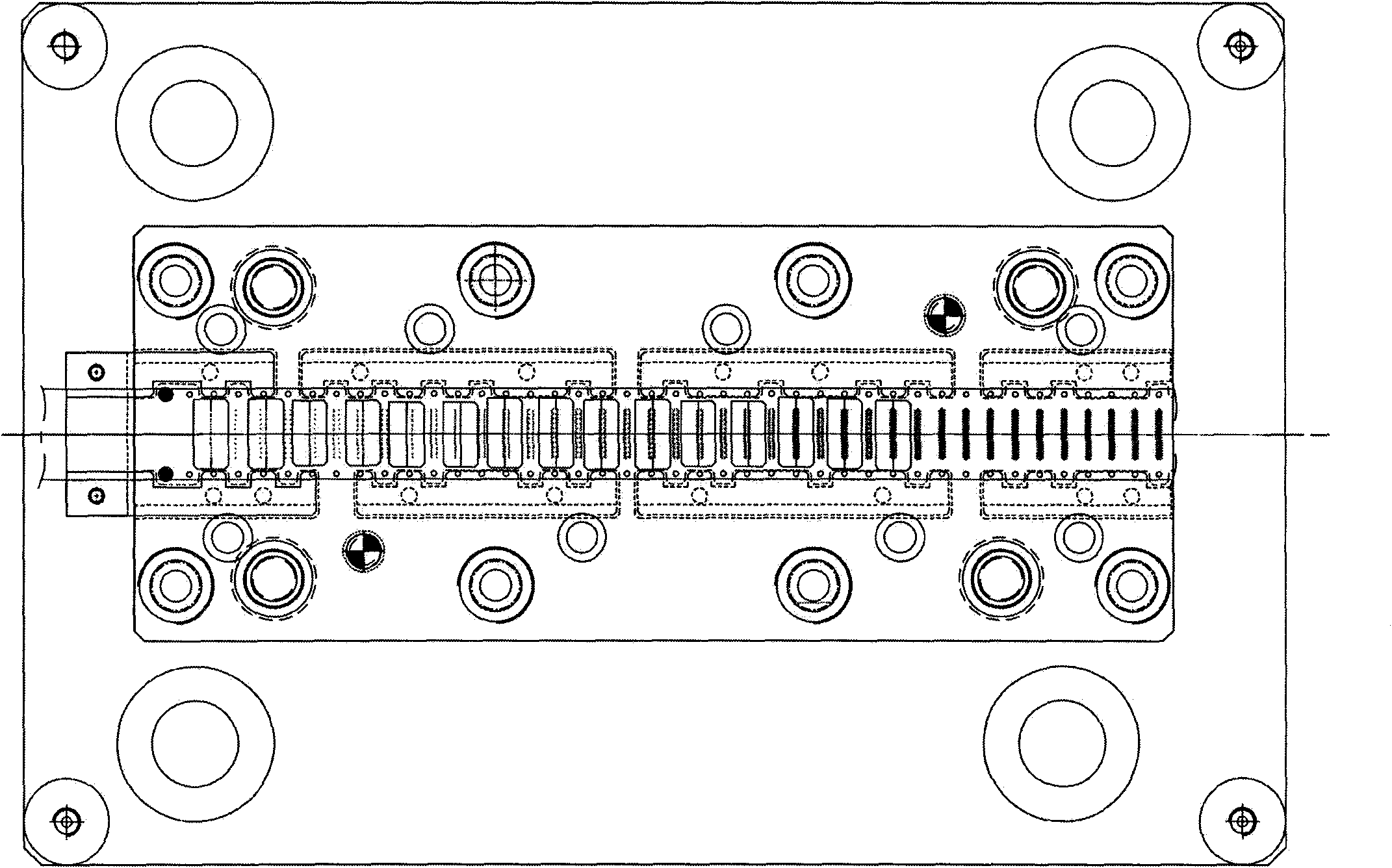

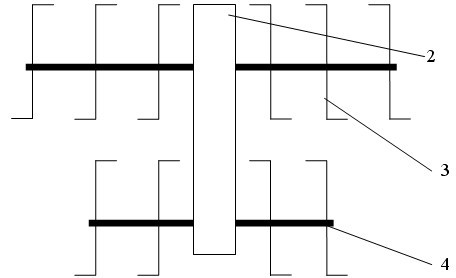

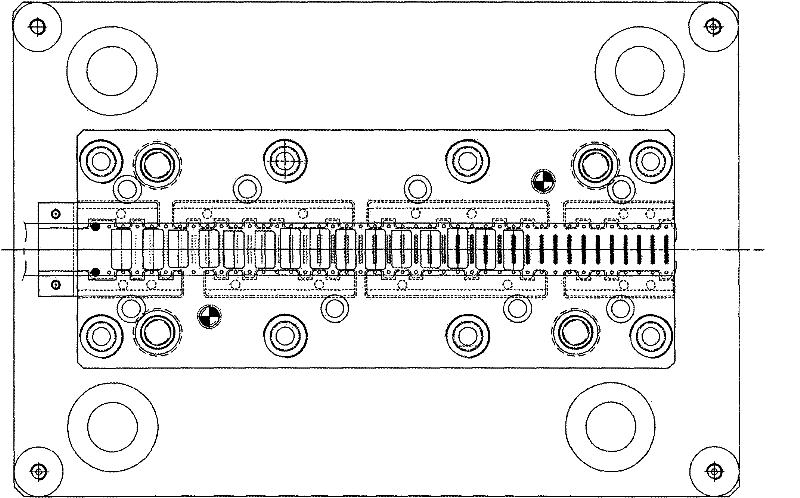

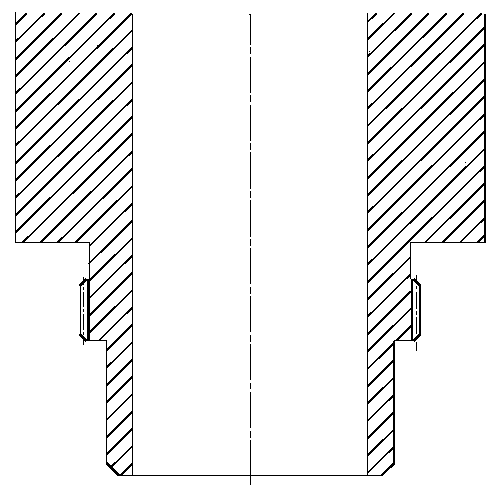

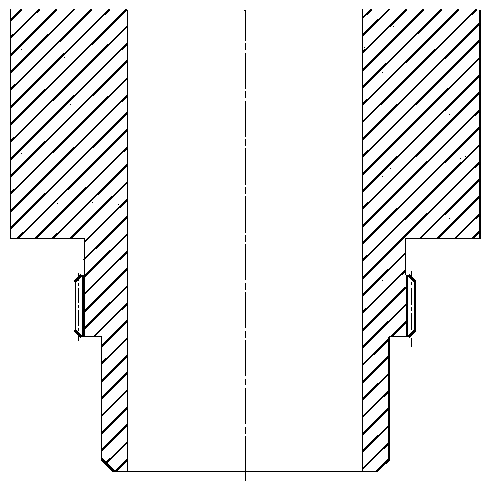

Progressive die integrating small hole punching and forming

The invention discloses a progressive die integrating small hole punching and forming, which is characterized in that: the progressive die comprises an upper die, a lower die, a male die, a female die and a secondary precision guide mechanism, wherein the male die is arranged in the upper die; the female die is arranged in the lower die; and the upper die and the lower die are connected together by secondary precision guide mechanism. The progressive die integrating small hole punching and forming provided by the invention performs punching operation on a punch press at a speed of 500 times per minute and can form a product by punching for one time without secondary processing; and meanwhile, when the die is used for processing small holes, the production efficiency is high, the cost is low, and a small punch pin is unlikely to be broken in a high-speed punching process and has a long service life.

Owner:CHENGDU HOMIN TECH

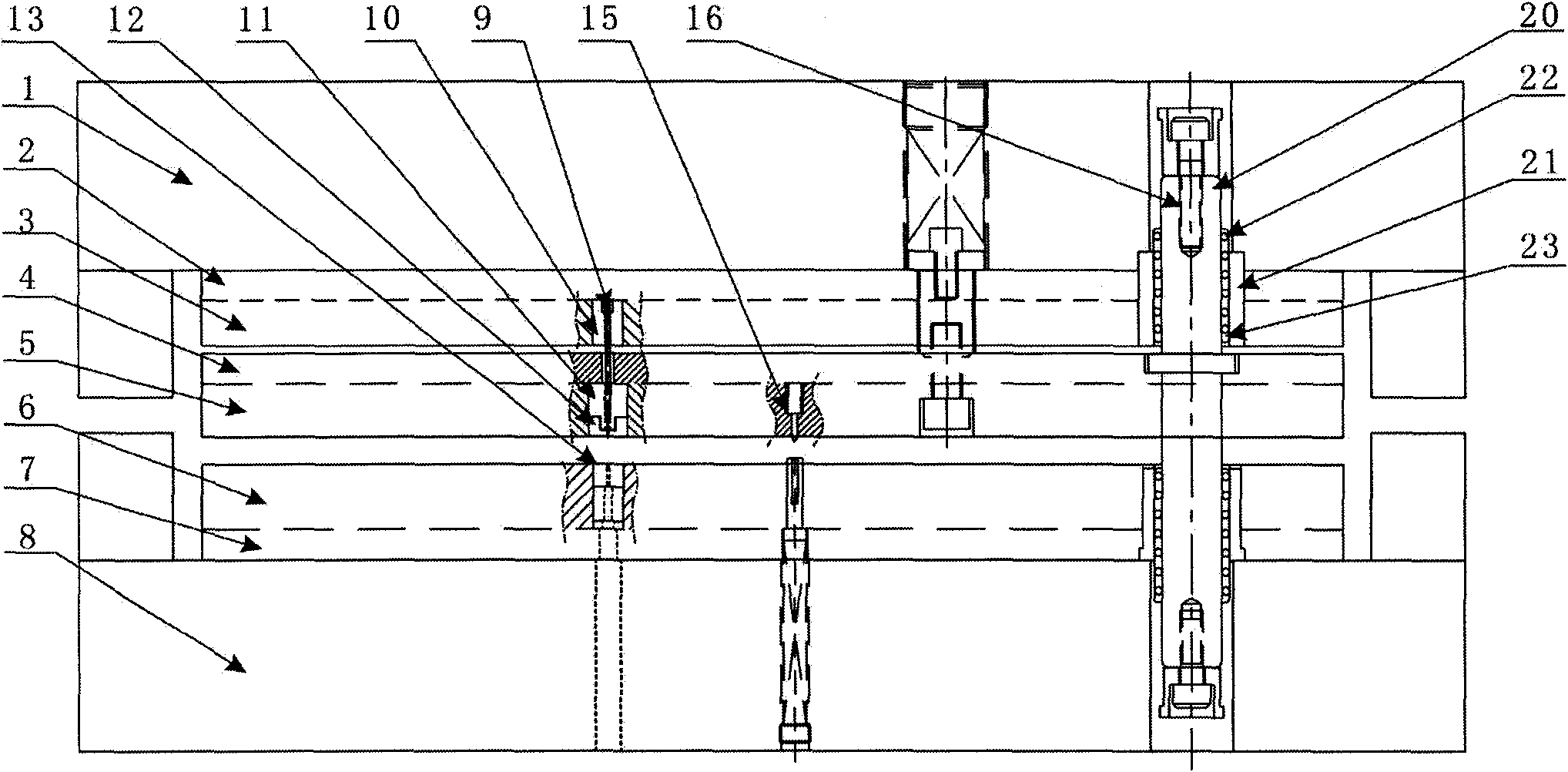

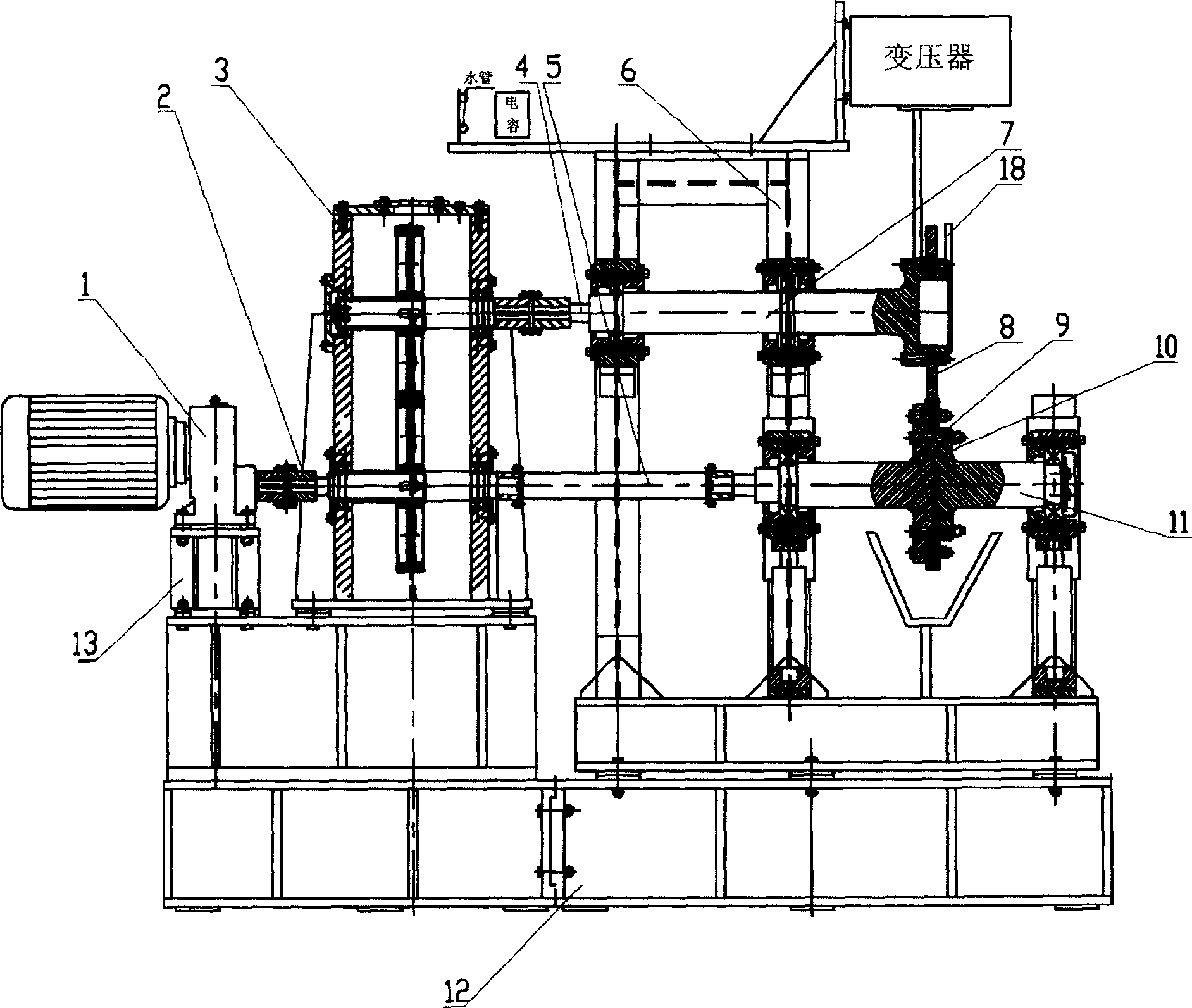

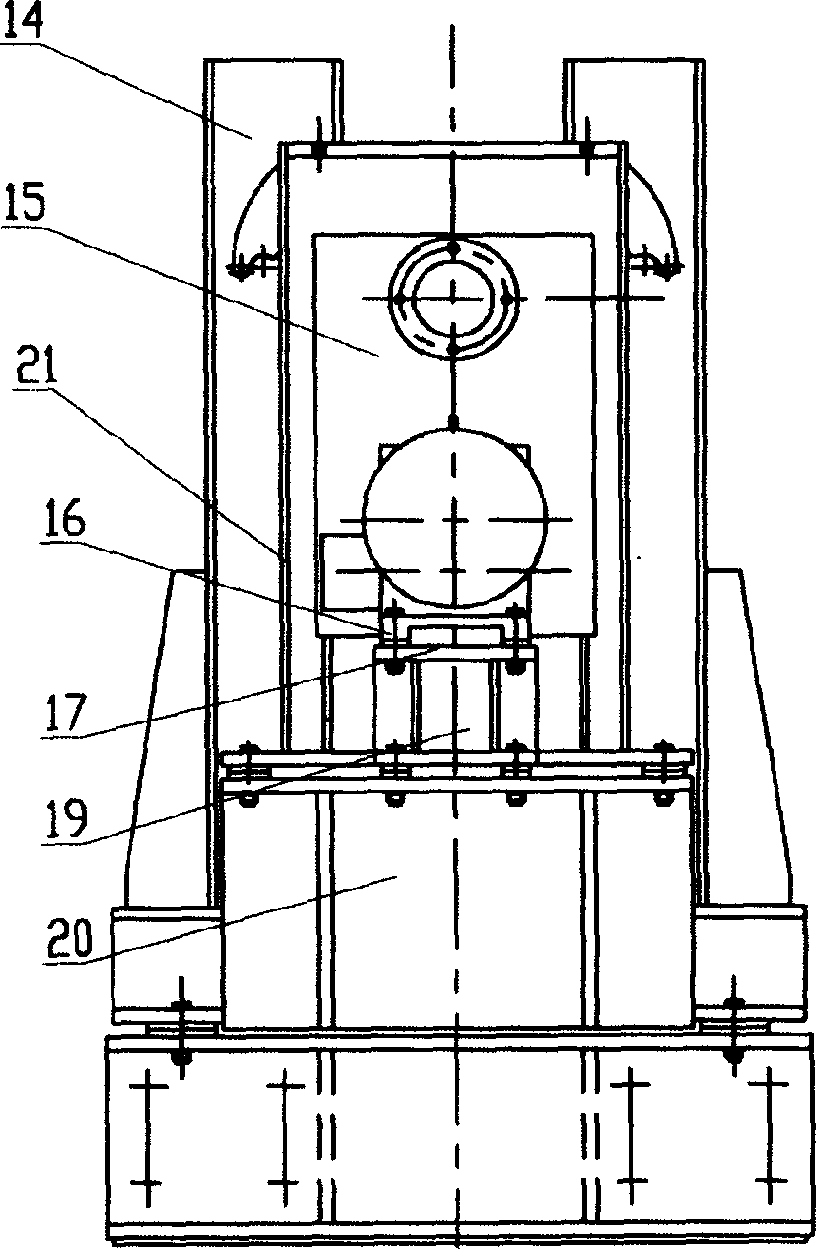

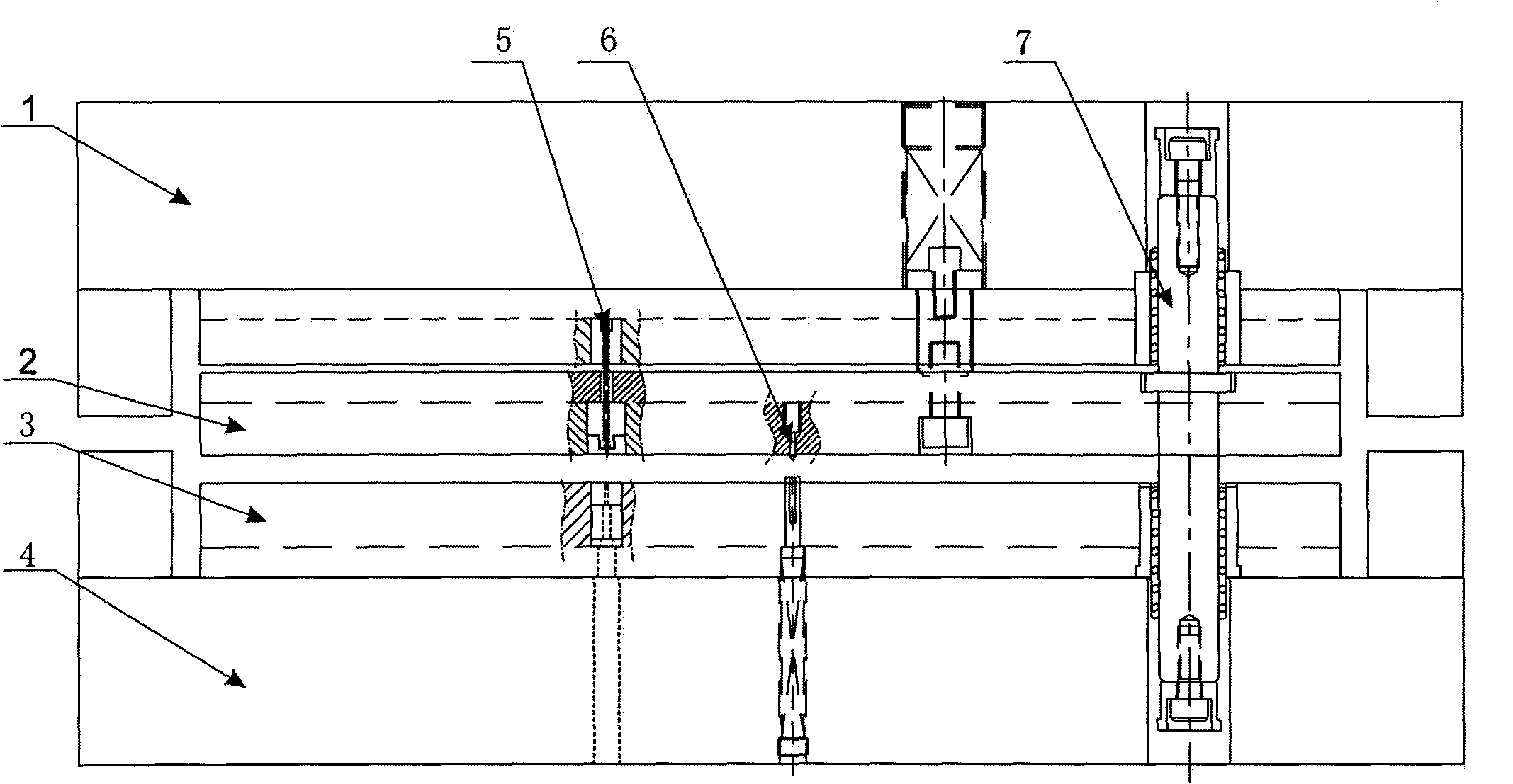

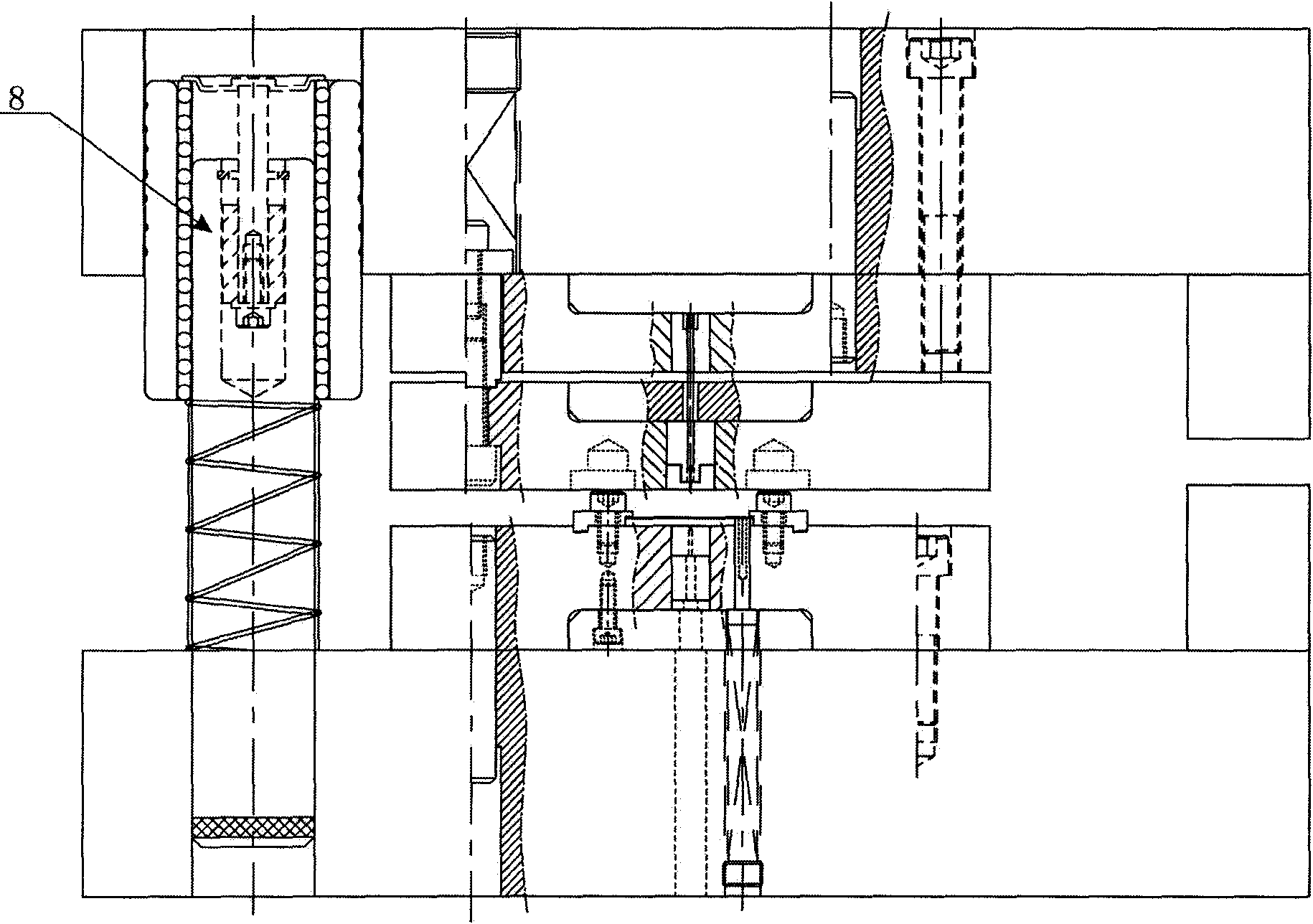

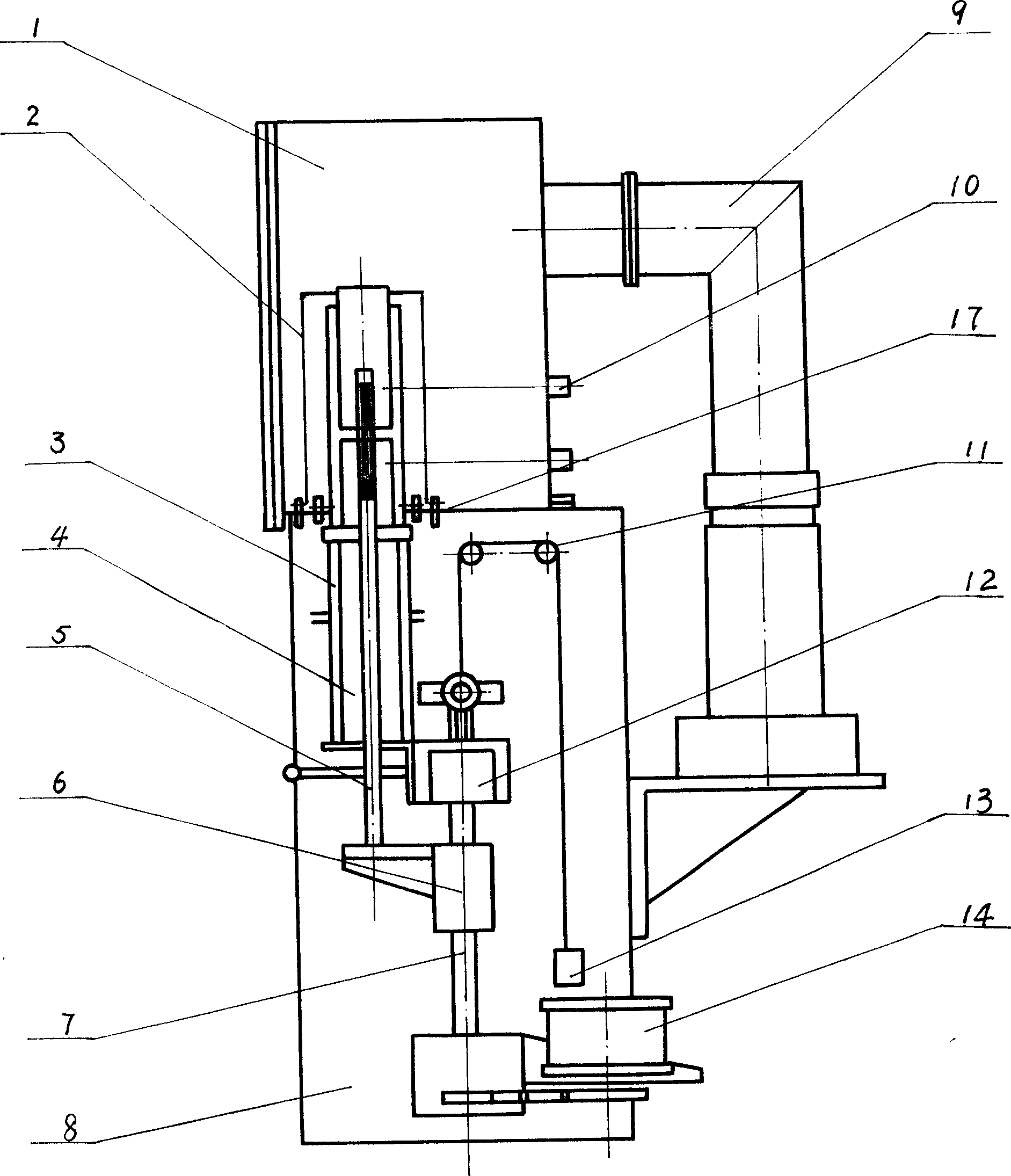

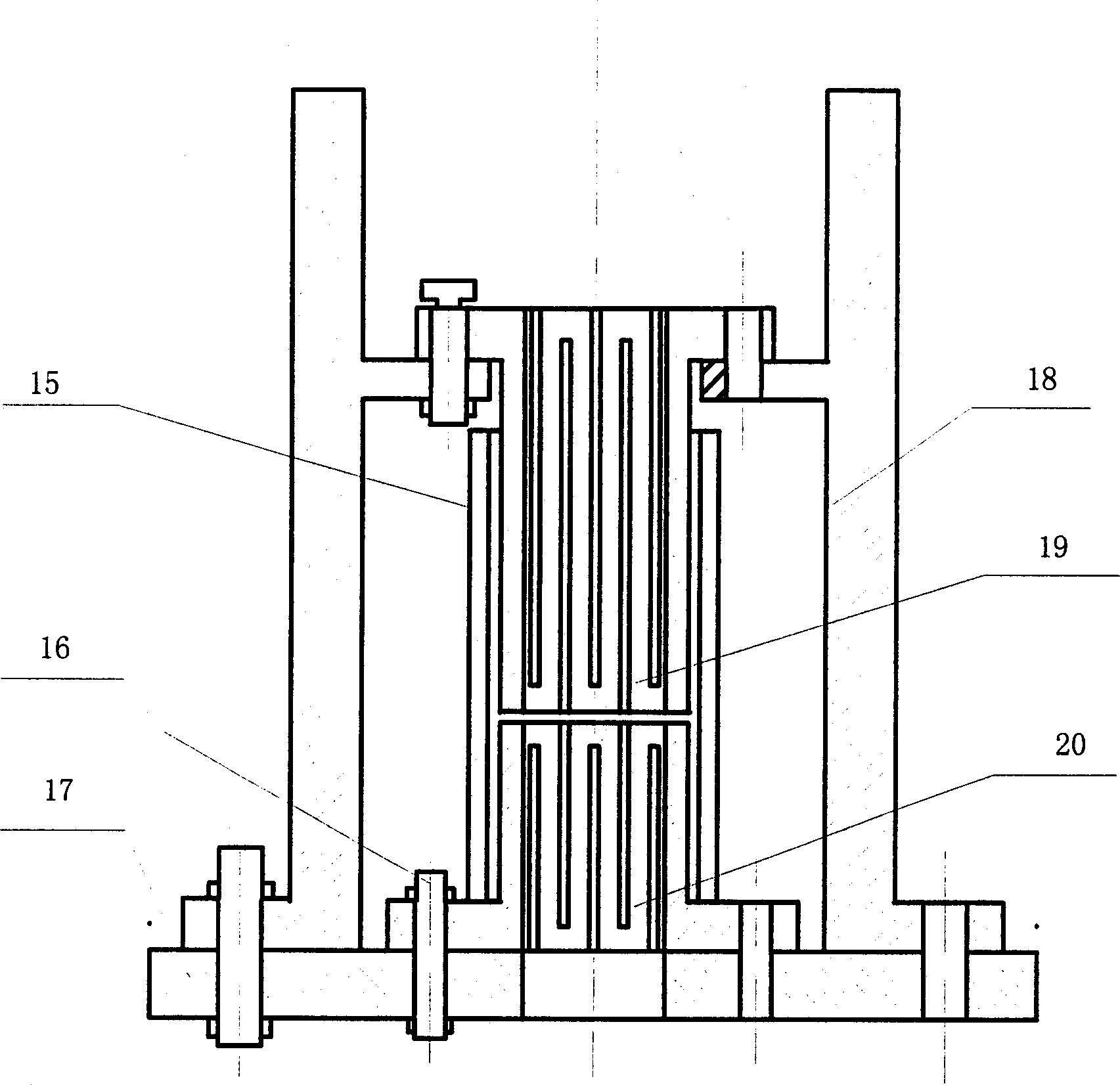

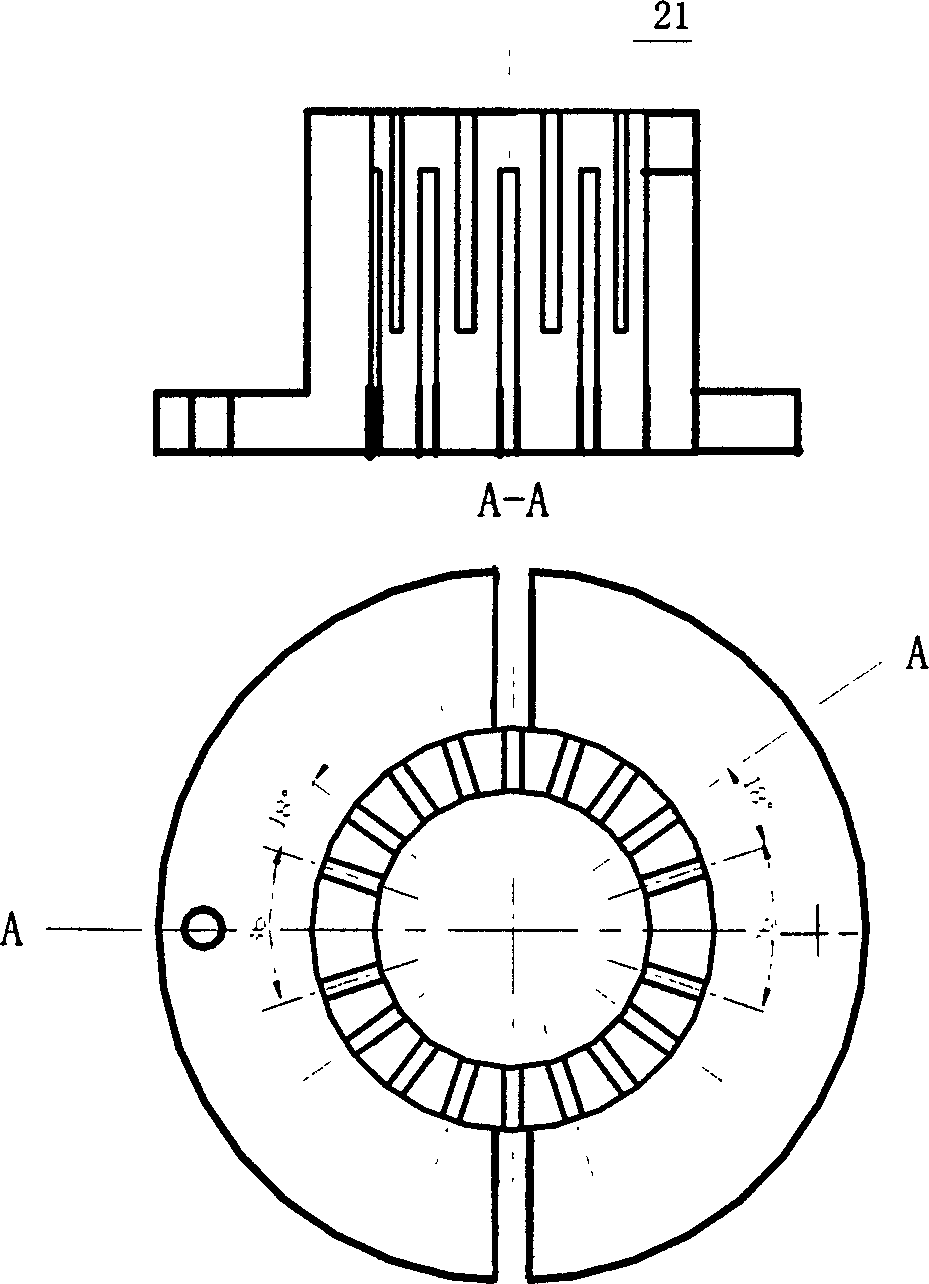

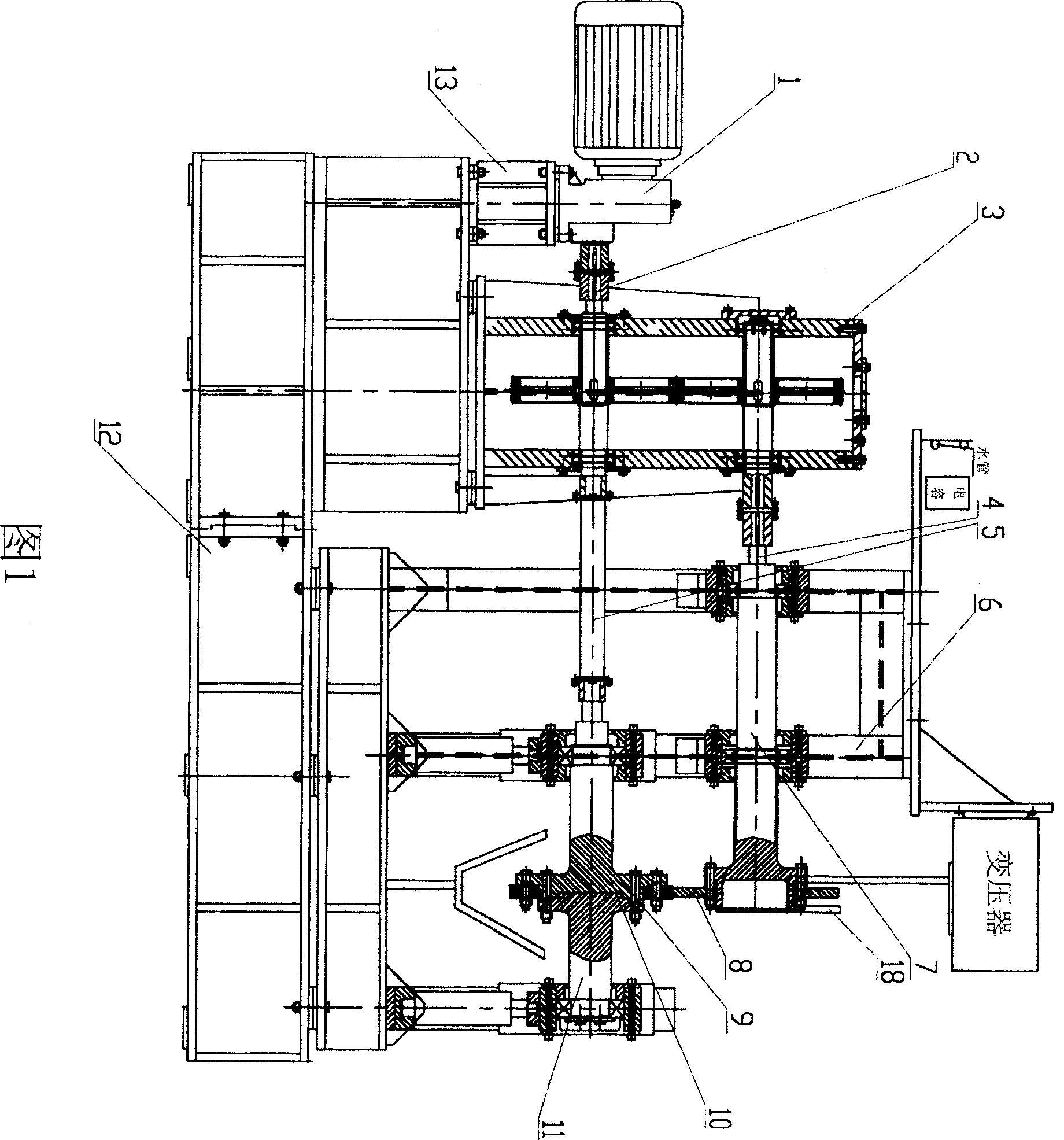

High temperature sliding wear and thermal contact fatigue testing machine for material

InactiveCN1724994AImprove efficiencyLow costUsing mechanical meansInvestigating abrasion/wear resistanceHydraulic pumpPressure sense

The invention is a tester for high temperature sliding abrasion and thermal contact fatigue material, belonging to the technical field of material processing and friction and abrasion testing, comprising friction auxiliary, pressure regulator, heater, and lubricating device, where the friction auxiliary comprises speed reducing motor, variable frequency speed regulating motor, supporting seat, shaft coupler, distribution gear box, universal connection shaft, machine frame, top friction auxiliary system, bottom friction auxiliary system, and friction piece, where the top friction auxiliary system comprises rotating shaft, bearing base, pressure plate, and top friction piece, the bottom friction auxiliary system comprises right and left rotating shafts, clamping chuck, bottom friction piece and bearing base, the pressure regulator comprises two groups of lift hydraulic cylinders, hydraulic pump, pressure sensing instrument and displaying instrument, the heater comprises induction heating coil, and water cooled system, the lubricating device comprises nozzle, and oil feeding system, the hydraulic system comprises electromagnetic switched electromagnet, and electric contact relay. The advantages of the invention lie in that: the equipment is simple in structure, the number of parts is small, the efficiency is high and the cost is low and it is applied to scientific research and production field simulation.

Owner:UNIV OF SCI & TECH BEIJING

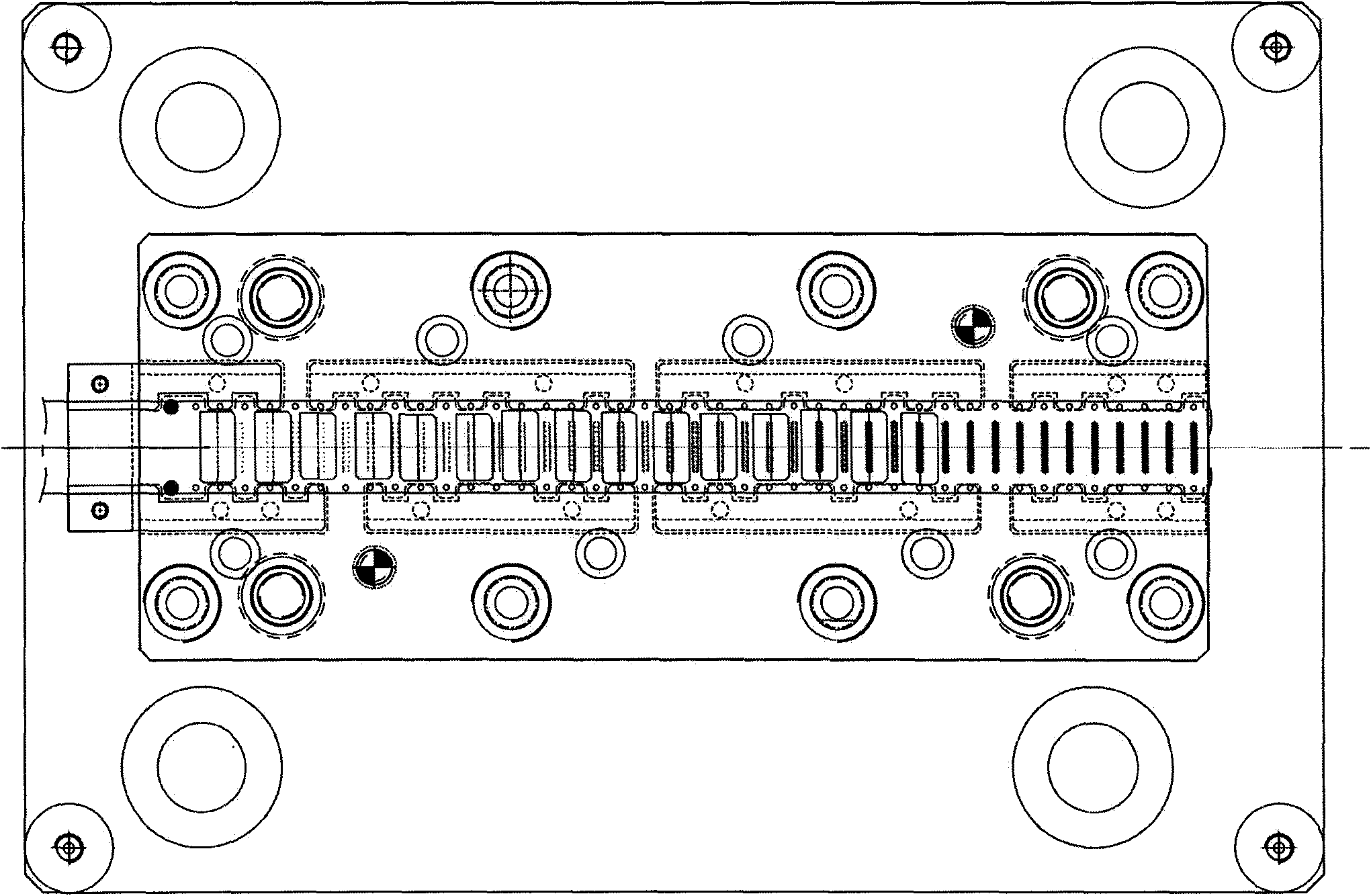

Small hole rapid molding process

The invention discloses a small hole rapid molding process which comprises the following steps of: A. assembling a mould and installing with a material; B. punching a guide hole; C. grading; D. punching small holes; E. punching a small hole set; and F. sequentially circulating and repeating the step B, the step C and the step D until punching and cutting with the material for a metal to be processed is finished. When small hole processing is carried out by adopting the small hole rapid molding process, the mould is installed in a high-speed punch, working with more than 500 punching times per minute is carried out on the high-speed punch, and a product is once stamped and molded without needing secondary processing. The process has high production efficiency and low cost. Meanwhile, the invention also has the following characteristics that: the punching head of a convex mould is not easily broken and has long service life in the high-speed punching process.

Owner:CHENGDU HOMIN TECH

Mechanical three-shaft type high-speed-ratio automobile gearbox

InactiveCN103758947ALow failure rateImprove reliabilityToothed gearingsGearing controlGear wheelControl theory

The invention discloses a mechanical three-shaft type high-speed-ratio automobile gearbox which comprises an input shaft, an output shaft, an intermediate shaft and transmission gears arranged on the shafts. Due to the fact that each stage of transmission gear of the gearbox is a point-line gear, running of the gearbox can be more stable, the working noise of the gearbox can be reduced, and the service life of the gearbox can be prolonged; due to the fact that the point-line gears are large short-addendum gears, the large gear ratio can be achieved, and through the design of the limit of the gear ratios of the transmission gears, the maximum transmission ratio of the first gear of the gearbox can reach above twelve, the maximization of the transmission ratio of the first gear of the gearbox is achieved, the transportation requirement for steep slope overloading of automobiles is met, an auxiliary gearbox does not need to be added in front of or in back of the gearbox, the manufacturing cost of the gearbox of a heavy-load automobile is reduced, the failure rate of the gearbox is reduced, and the reliability of the gearbox is improved; in addition, the transmission structure of the gearbox does not need to be changed, so the gear shifting operation can be more convenient and flexible.

Owner:谭富春 +1

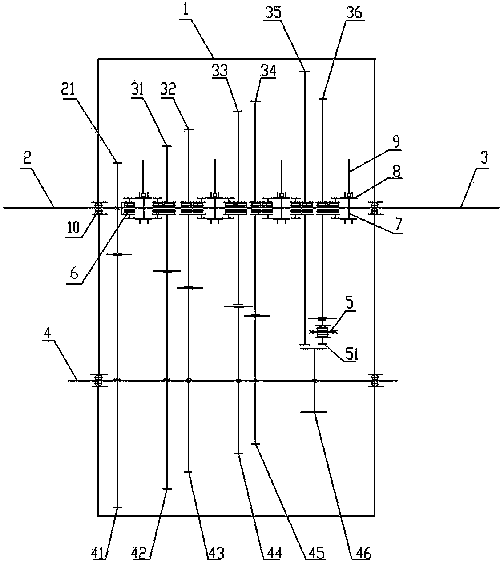

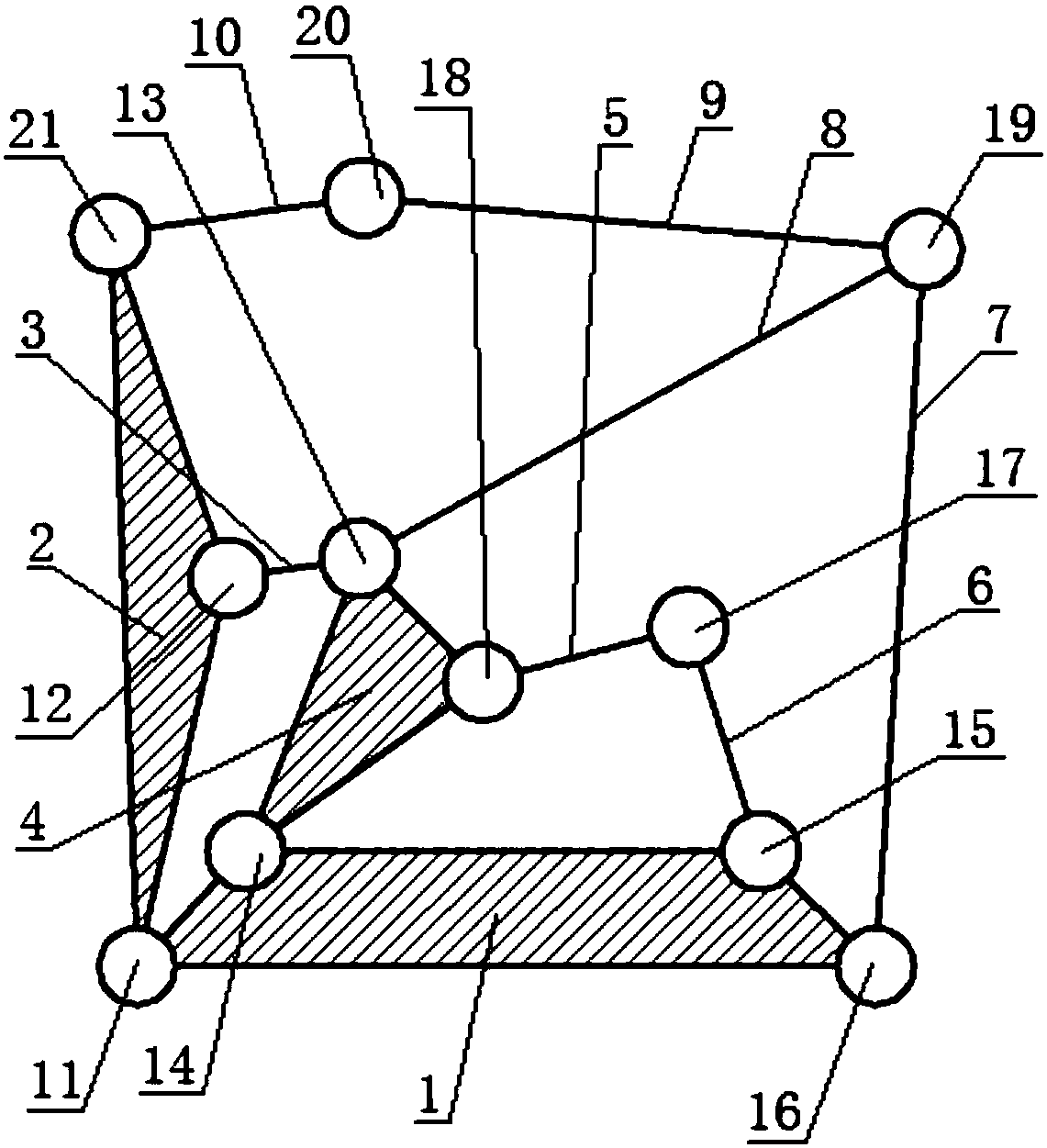

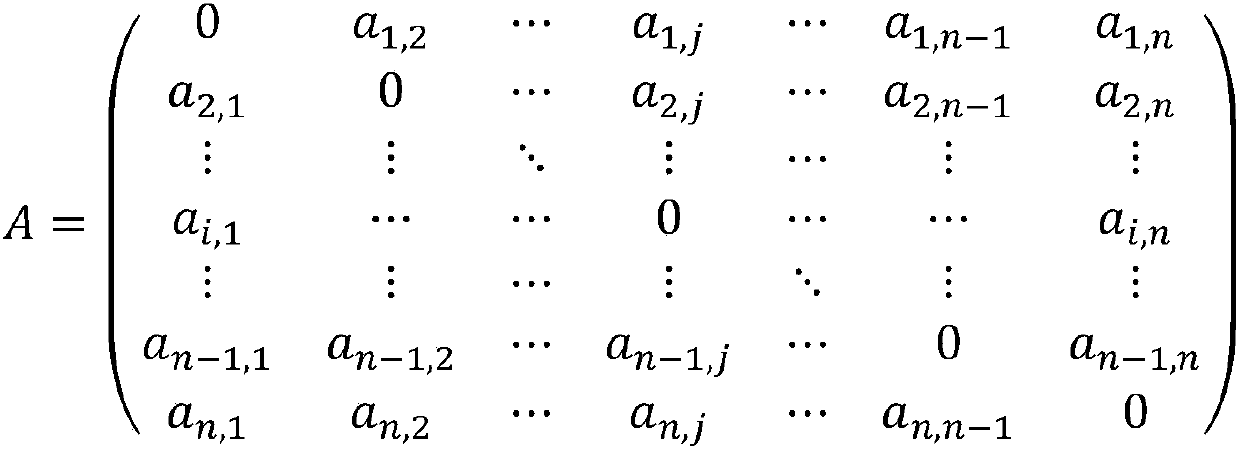

Number-matrix description method of planar closed multi-joint kinematic-chain

InactiveCN107944097AOmit relational expressionAvoid lossDesign optimisation/simulationComplex mathematical operationsTopological graphKinematic pair

The invention relates to the field of mechanism kinematic-chains, and discloses a number-matrix description method of a planar closed multi-joint kinematic chain. Components and kinematic pairs, whichare Pn, of the kinematic chain are numbered, and an n x n number matrix A is generated. According to the number-matrix description method of the planar closed multi-joint kinematic chain of the invention, relation expression of a topology graph is omitted, information loss is prevented, the number matrix corresponds to the kinematic chain in a one-to-one manner, and can uniquely represent the kinematic chain, and a kinematic-chain structure diagram can be directly drawn by the number matrix.

Owner:WUHAN UNIV OF SCI & TECH

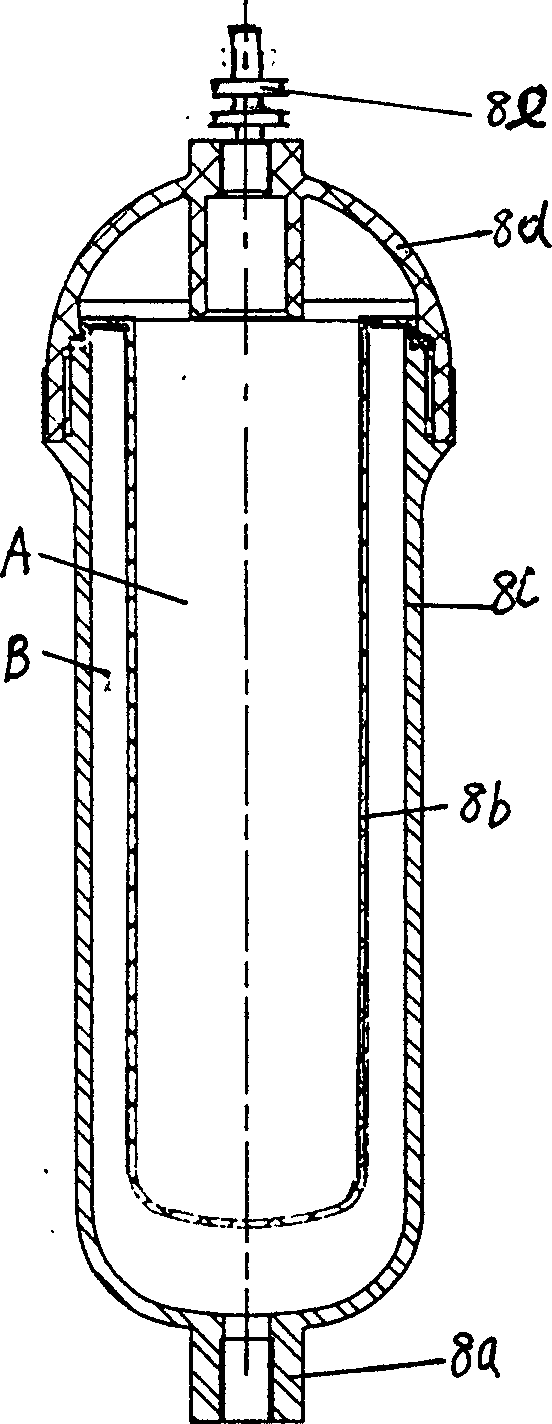

High gradient biregion heating directional solidification device

InactiveCN1597189AAvoid reactionStructure diagramFrom frozen solutionsDirectional solidificationHeating system

A high-gradient directional solidifying apparatus features that its heating system has two heaters positioned respectived at liquid-solid interface and molten region, its drawing unit has mechanical and manual ones which can be electromagnetically switched, and its crystallizer is a dual-layer structure with cooling water jacket.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

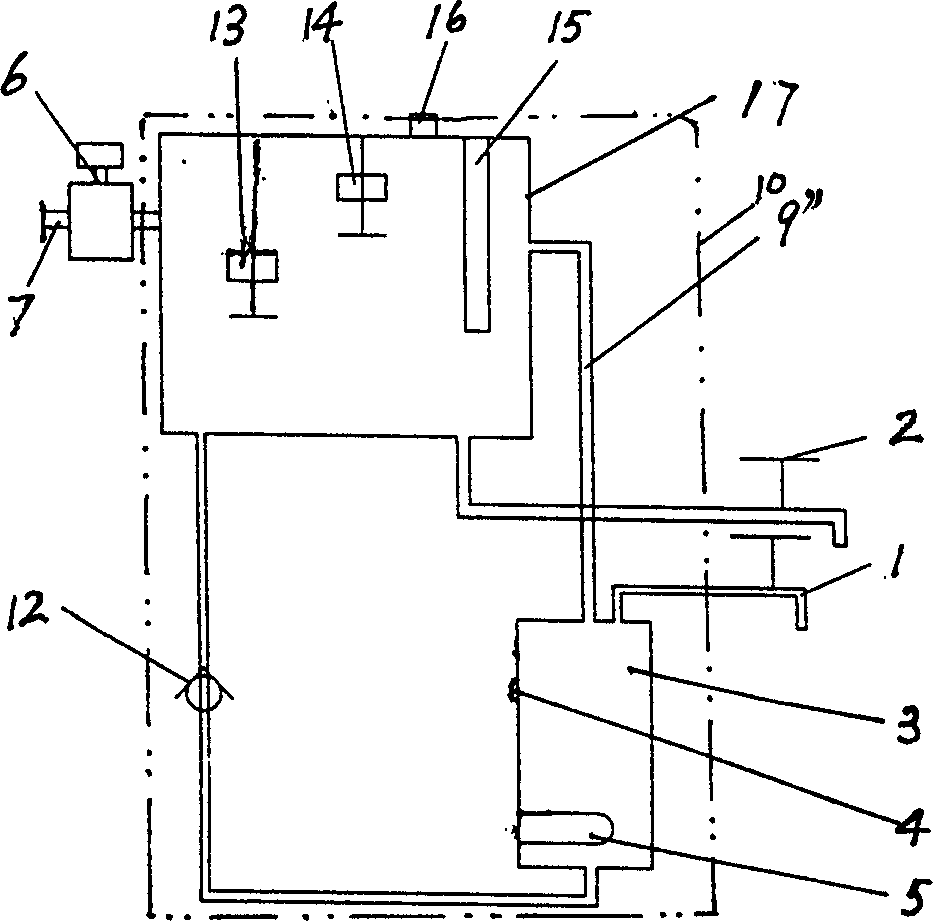

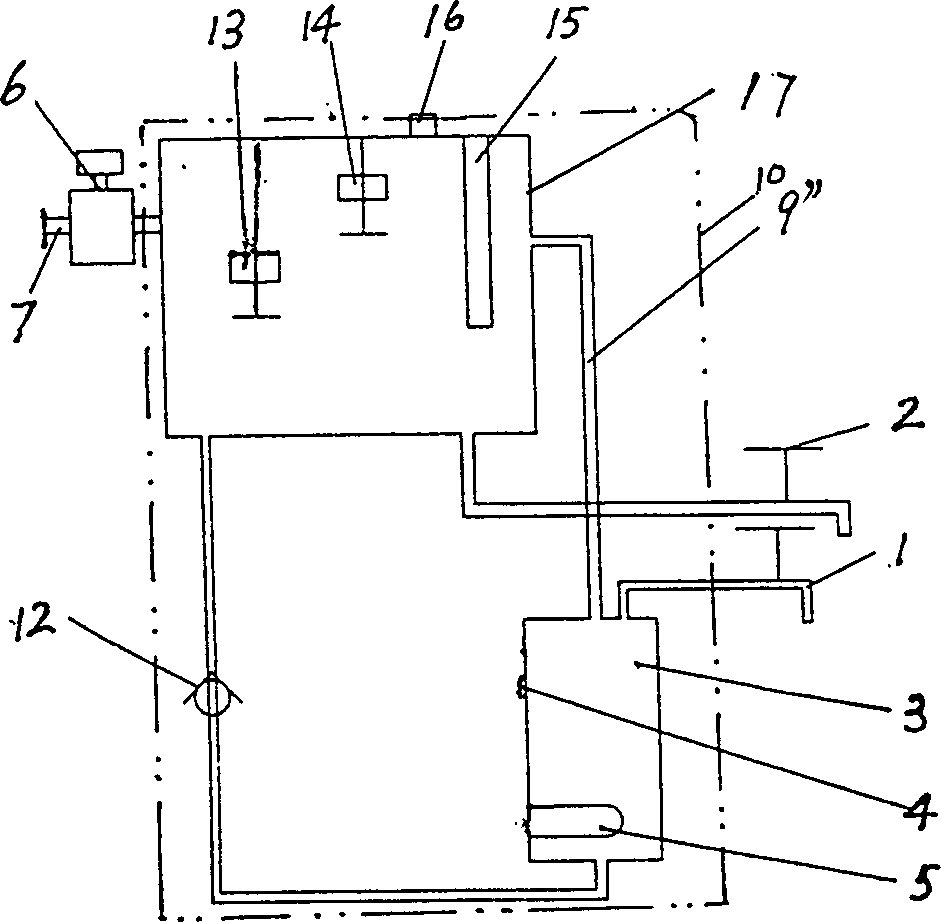

Water cleaning and heating device free from secendary pollution

InactiveCN1460821ASolve the impactSolve the problem that must be connected to the atmosphereWater/sewage treatment by irradiationWater heatersAtmospheric airEngineering

The clean water heater which is connected with clean water source, can be used for providing cold and hot drinking water instantaneously and conveniently and does not produce secondary pollution includes a shell body with cold water tap and hot water tap, clean water intake tube with electromagnetic valve and heating internal container with temp. controller and electroheating wire, in which the cold water tap is directly connected with clean water intake tube, and the hot water tap is communicated with heating internal container, and said heating internal container is communicated with clean water intake tube by means of electromagnetic valve.

Owner:蒋仕美 +1

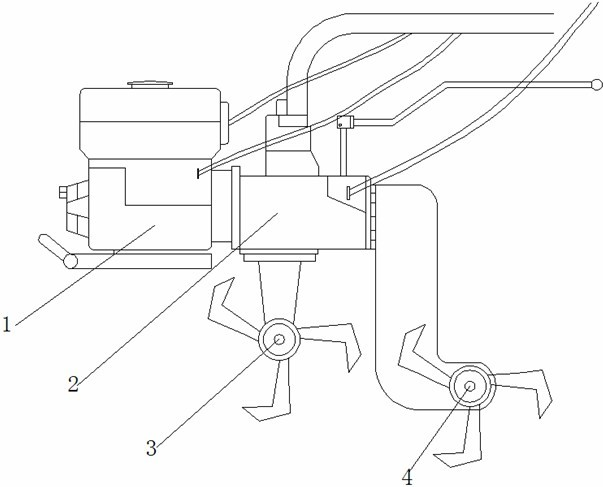

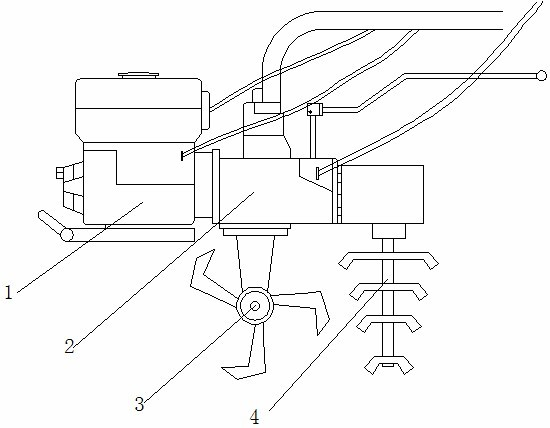

Walking type self balance mini-tiller

InactiveCN102612872AImprove convenienceImprove operational control difficultyTilling equipmentsAgricultural engineeringStructural engineering

The invention discloses a walking type self balance mini-tiller, which comprises an internal combustion engine, a transmission box and a main rotary blade, wherein a cutter shaft of the main rotary blade is parallel to the ground and is in transverse arrangement, the mini-tiller also comprises an auxiliary rotary blade realizing the balance effect, the auxiliary rotary blade is positioned behind the main rotary blade, and the auxiliary rotary blade is connected with a motive power mechanism and is driven to rotate by the motive power mechanism to realize the cutting on the soil, so the effect of balancing the main rotary blade and the goal of auxiliary deep cultivation are reached. Through the soil cutting effect of the auxiliary rotary blade in additional arrangement, the effect of balancing the vibration caused by the main rotary blade is realized, and the vibration degree and the operation and control difficulty of the existing small-size and miniature rotary tiller are reduced. Meanwhile, the cultivation effect of the existing miniature rotary tiller is also changed, the walking type self balance mini-tiller can realize the shallow cultivation and partial deep loosening, in addition, the shallow cultivation and the partial deep loosening adopt the layered operation but are completed at the same time, and the cultivation can reach more than 30cm in depth.

Owner:SOUTHWEST UNIVERSITY

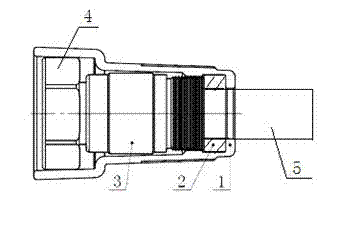

Cable connecting system

InactiveCN102832495ANot corrodedSolve protection problemsCouplings bases/casesMating connectionStructural engineering

The invention relates to the technical field of cable connectors, in particular to a cable connecting system. The cable connecting system comprises a connector, a mating connector, a protective shell and a front shell, wherein the protective shell is connectedly sleeved on the connector, a sealing ring is embedded into a joint of the tail end of the protective shell and the connector, the front shell is connectedly sleeved on the mating connector, and an opening of the front shell and an opening of the protective shell are opposite to each other and are hermetically and fittingly connected with each other. The cable connecting system well achieves that the connector is protected from being corroded by aqueous solution of acid and alkaline substances in an outdoor antenna feed system, is simple in structure, low in price and high in practical value and can be widely popularized and used.

Owner:CHANGZHOU AMPHENOL FUYANG COMM EQUIP CO LTD

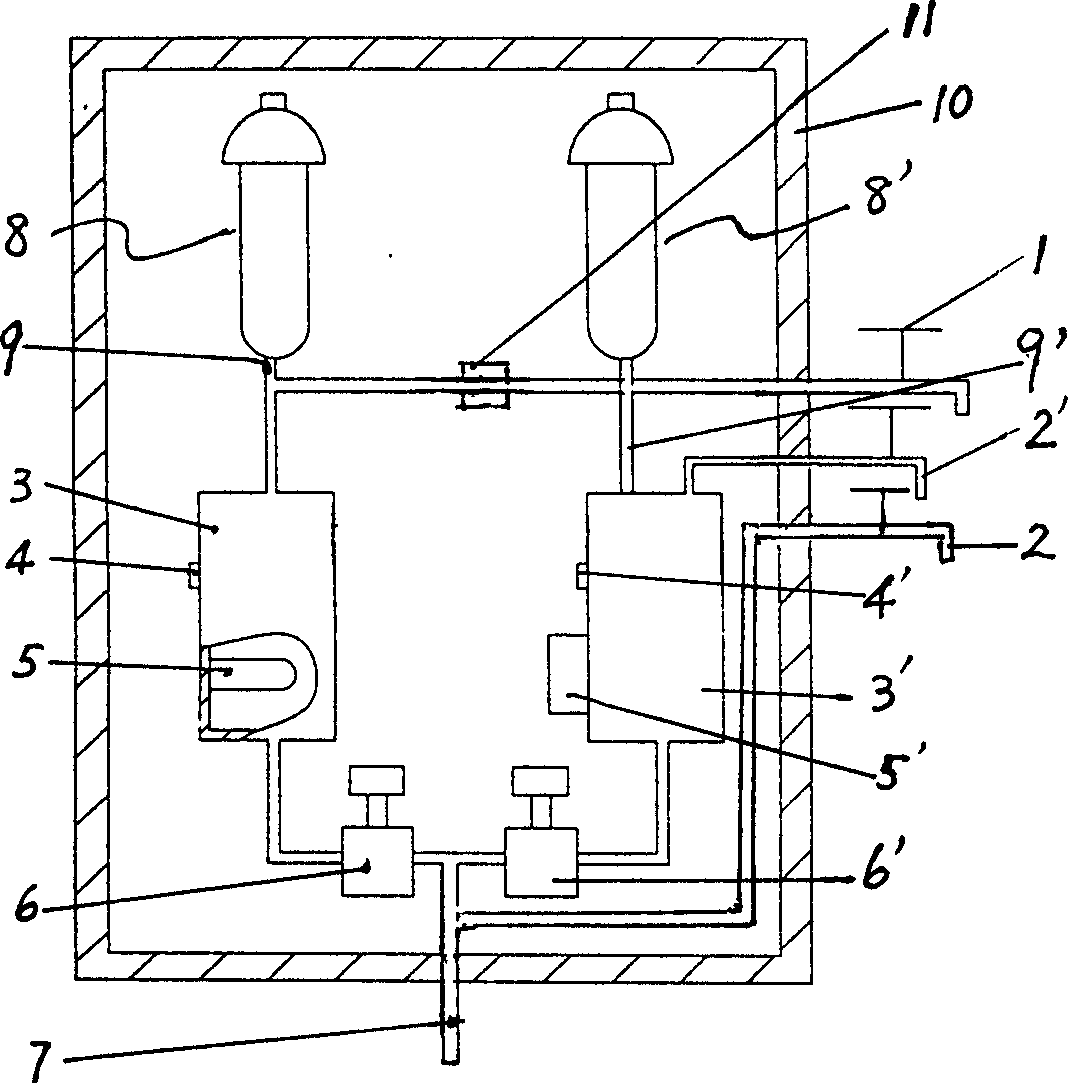

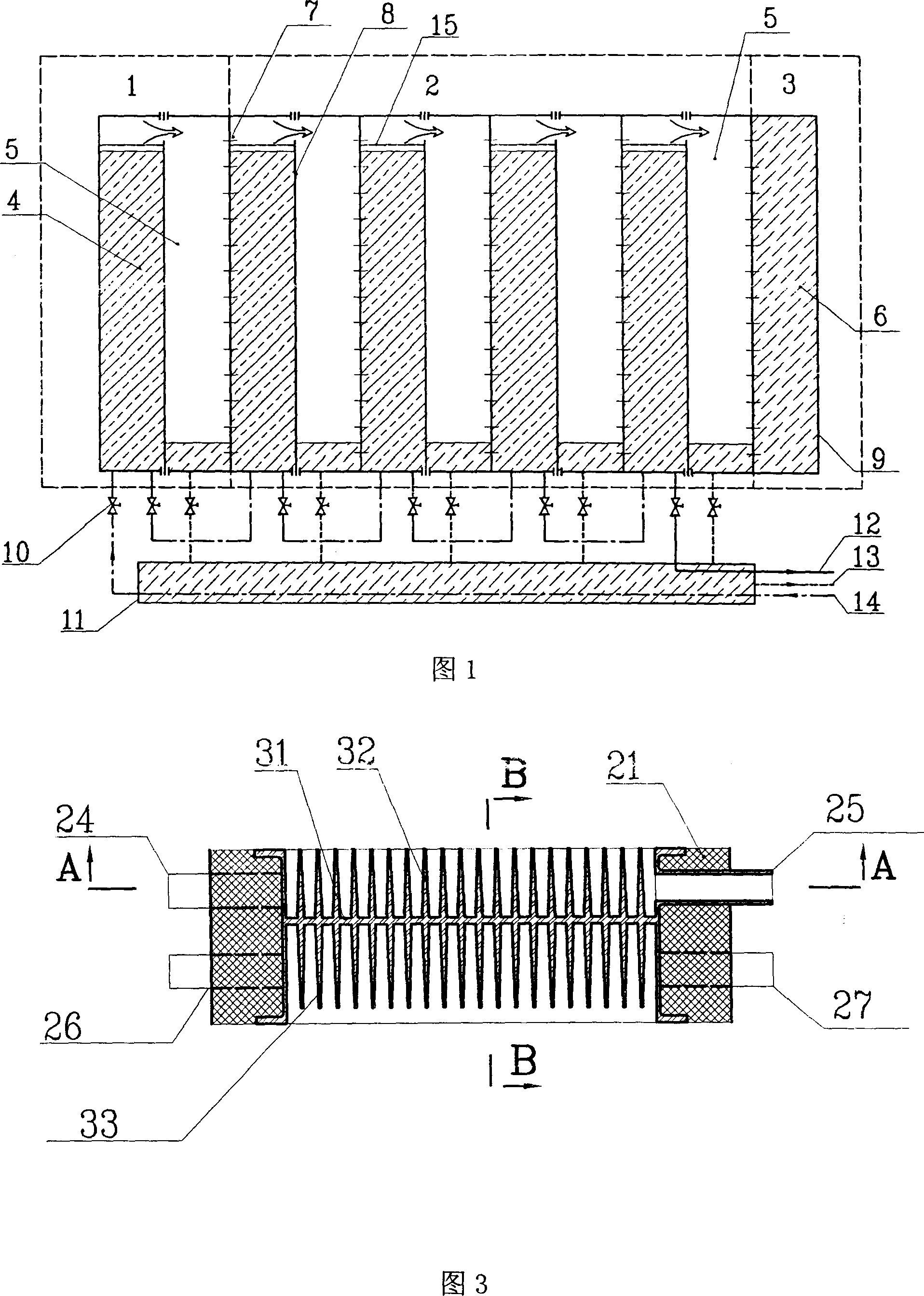

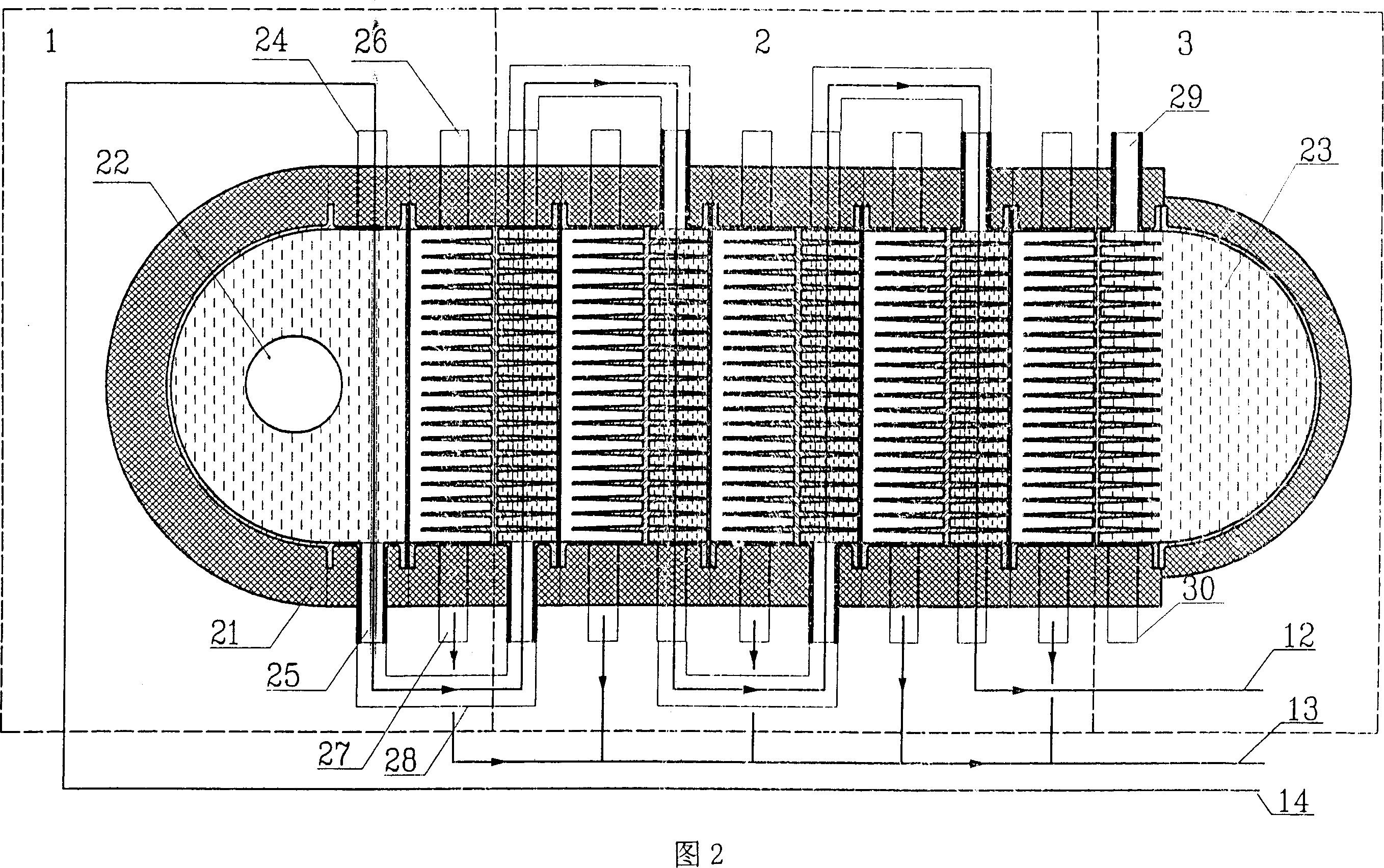

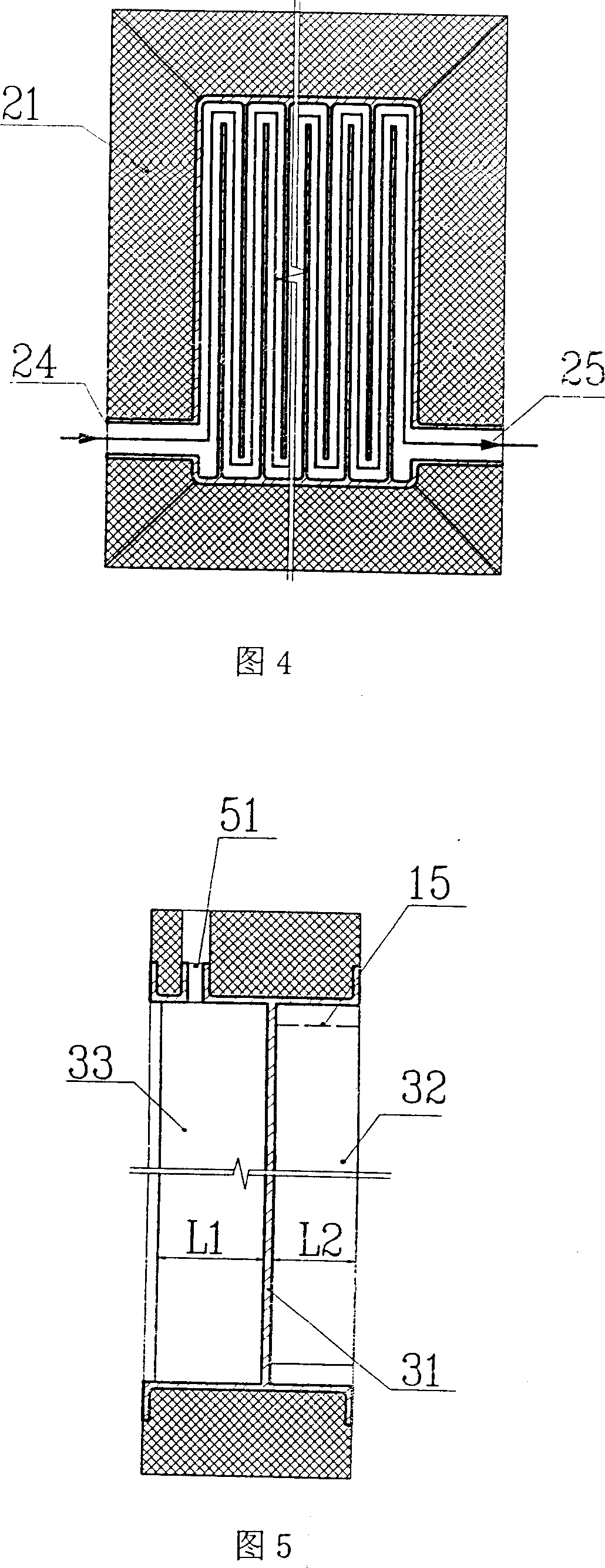

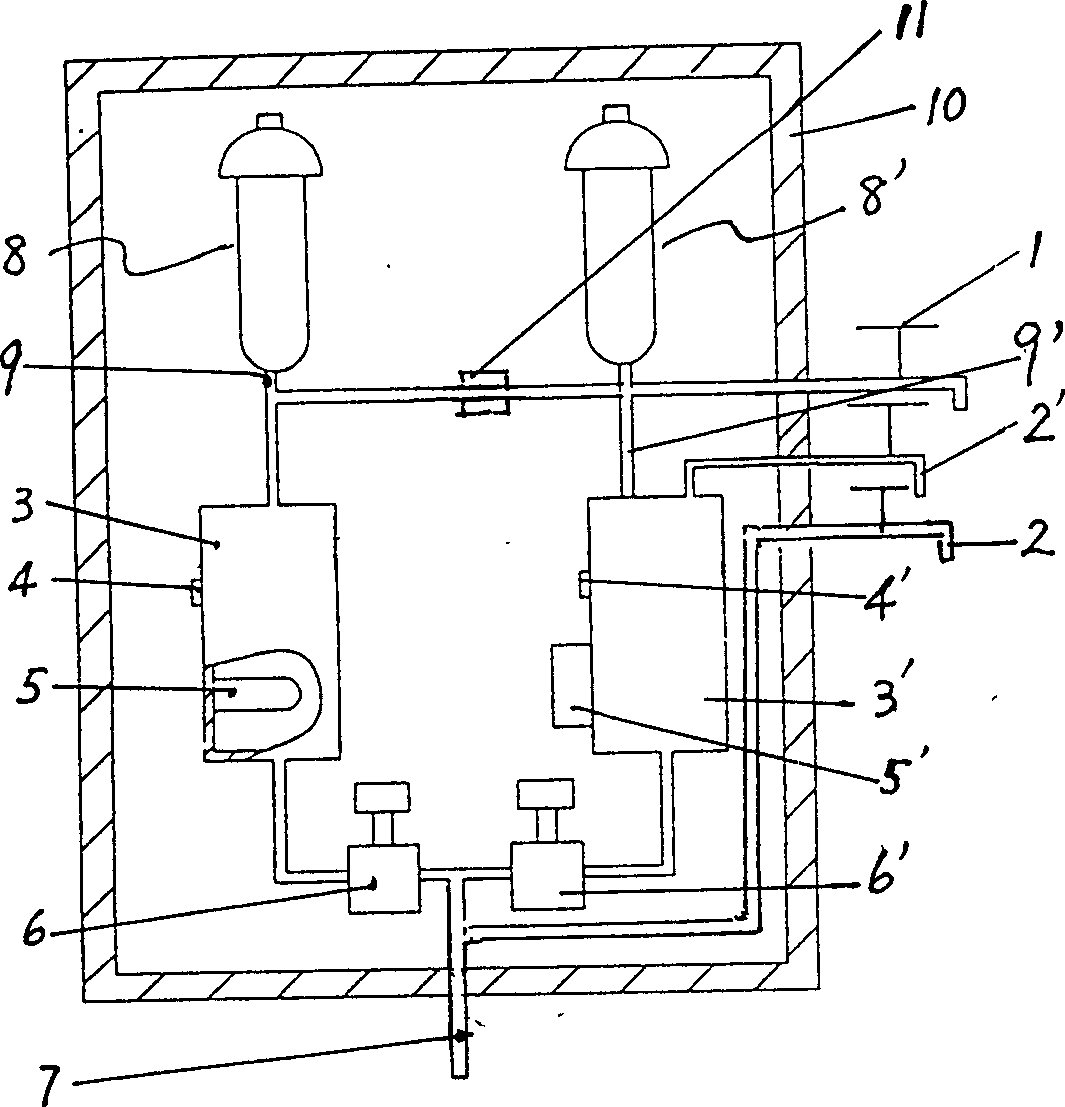

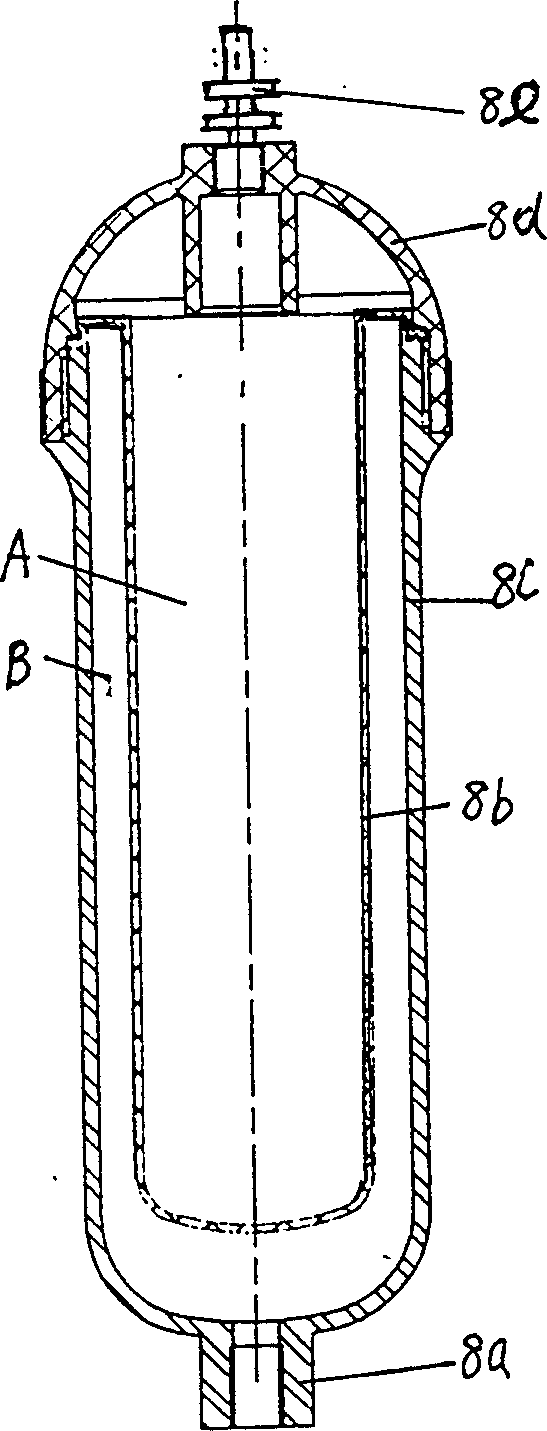

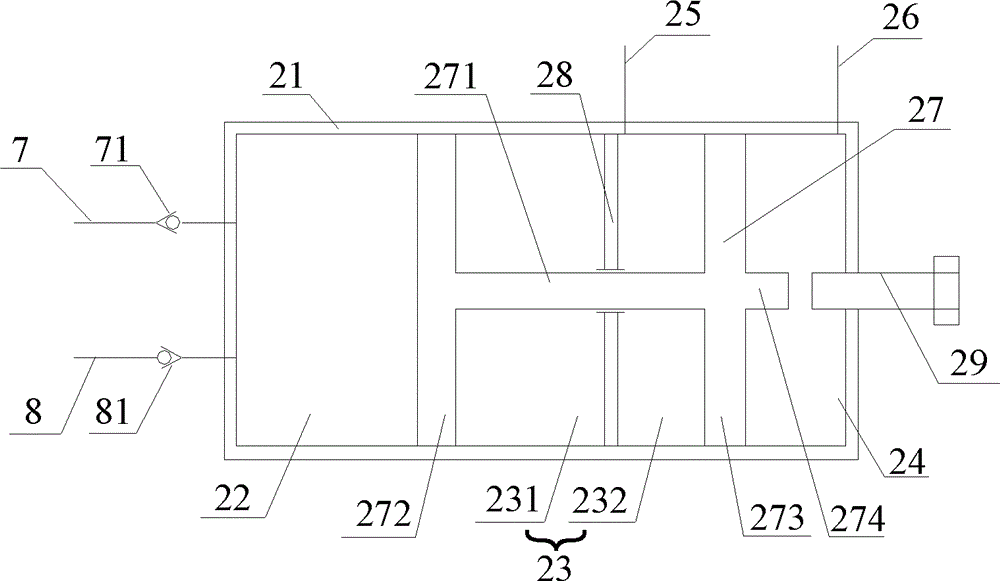

Thermal-energy stepwise multi-use solution concentrating-regeneration device

InactiveCN1995872ASolve the problem of rapid reduction in energy saving efficiencyReduce in quantityEvaporators/condensersMultiple-effect evaporationThermal energyLithium bromide

The invention discloses a solution concentration regeneration equipment for heat energy reuse in step, comprising steam kettle, heat exchanging system, peripheral pipe system and electric control system. The steam kettle comprises part in high-temperature zone, part in middle zone and part in condensing zone. Said part in the middle zone comprises outer wall, inlet port for dilute solution, outlet port for concentrated solution, installing port for inductor, solvent outlet port, vent and dissepiment between cavities. Said dissepiment between cavities comprises heat exchanging rib in evaporating room, middle plate of dissepiment between cavities and heat exchanging rib of condensing room. The invention can be widely applied in chemical condensing process, generator of air-conditioner with lithium bromide and so on. It can save energy and water resource greatly. It can decrease operation cost and compress equipment space. It is provided with huge environmental benefit and economical effect.

Owner:金爱民

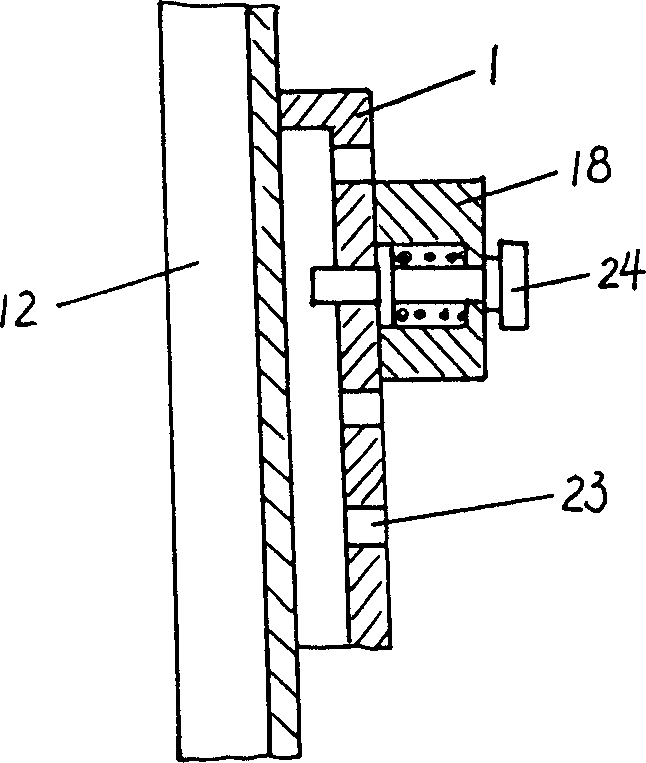

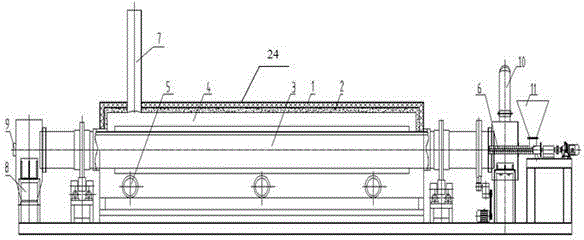

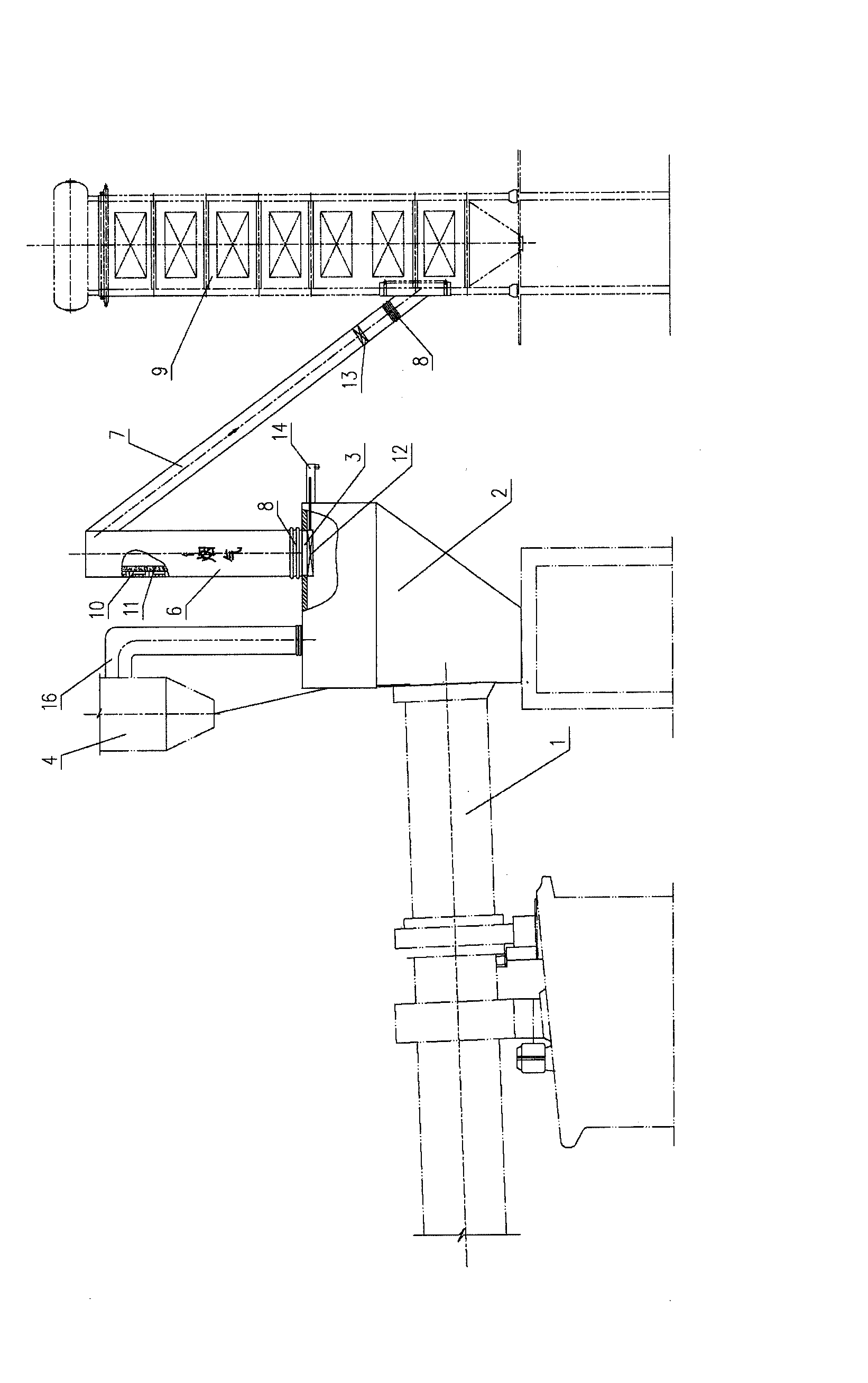

Externally heated high-temperature reduction fuming calcining rotary kiln

ActiveCN104677090AImprove recovery rateIncrease relative volatilityRotary drum furnacesWaste heat treatmentMaterials scienceGas pipeline

The invention discloses an externally heated high-temperature reduction fuming calcining rotary kiln. The externally heated high-temperature reduction fuming calcining rotary kiln is characterized in that a hearth external drum of a rotary drum (3) is provided with a high-temperature castable poured layer (2), the outer wall of the high-temperature castable poured layer (2) is reinforced by a steel plate shell (24), and a space between the steel plate shell (24) and the high-temperature castable poured layer (2) is filled with a heat-insulation material layer (1); oil and gas spray holes (5) are formed in a side of the rotary drum (3) and are communicated with an oil and gas ejection pipe (23) of an external heating system; a flue gas cooling and dust collecting device is arranged on a side of a kiln head of the rotary kiln, the temperature of a flue gas pipeline (10) of the flue gas cooling and dust collecting device keeps at 1050-1200 DEG C, and the temperature of an inlet of the flue gas cooling and dust collecting device is lower than 150 DEG C. The externally heated high-temperature reduction fuming calcining rotary kiln has the advantages that the externally heated high-temperature reduction fuming calcining rotary kiln can run stably and reliably and is high in metal oxide reduction rate and nonferrous metal evaporation rate, nonferrous metal in fume can be efficiently concentrated and recycled, the evaporation rate of lead in iron-bearing dust and the evaporation rate of zinc in the iron-bearing dust can respectively reach 90% and 95% at least, the grade of zinc oxide in the fume can reach 70% at least, and the occupation ratio of magnetic iron in calcined cinder can reach 80% at least.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

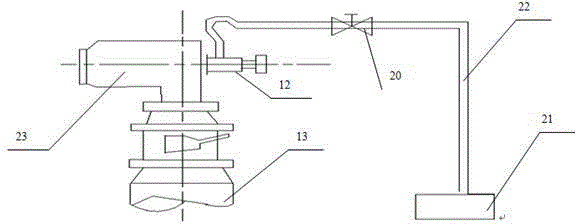

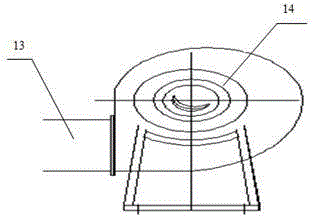

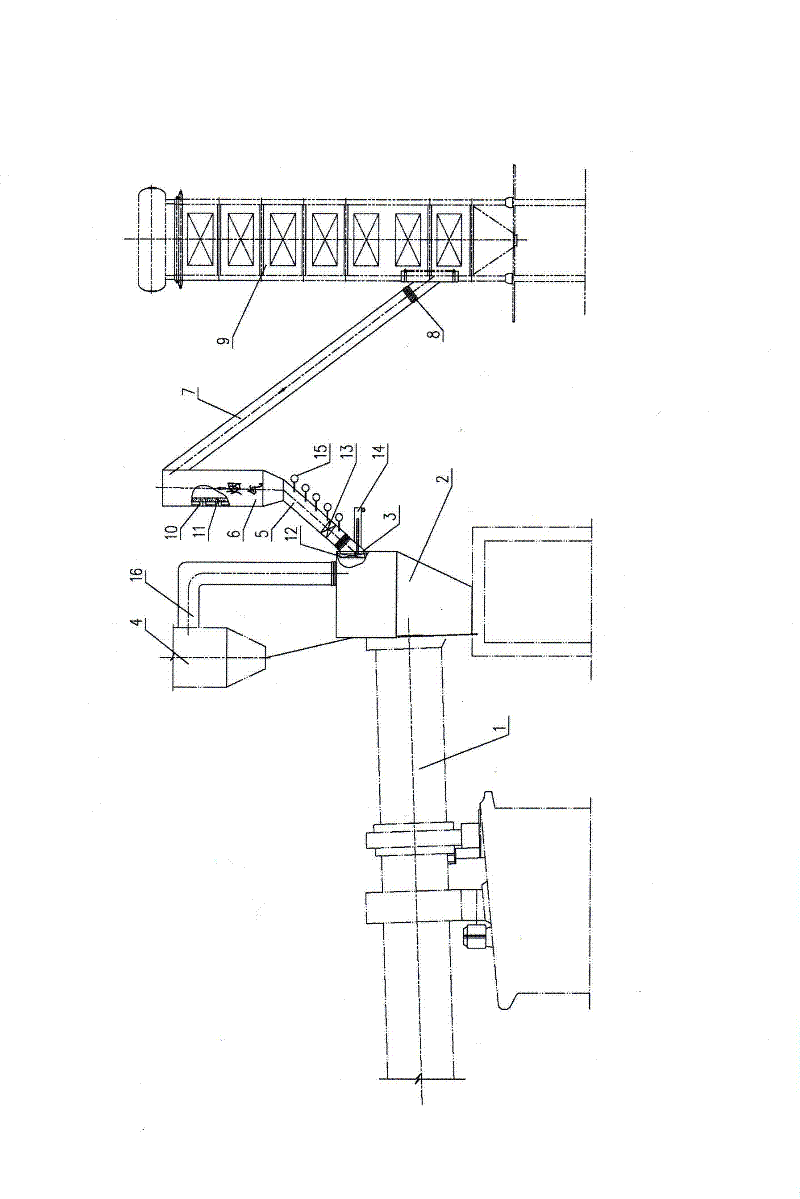

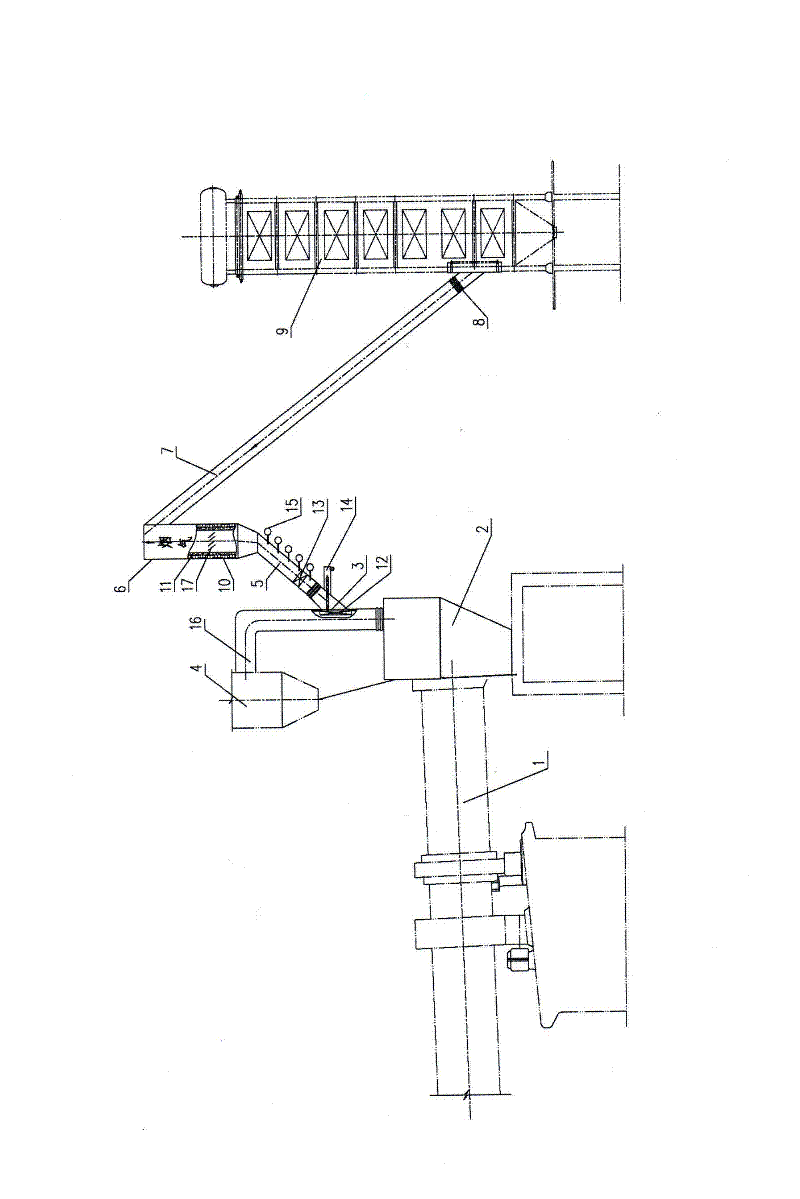

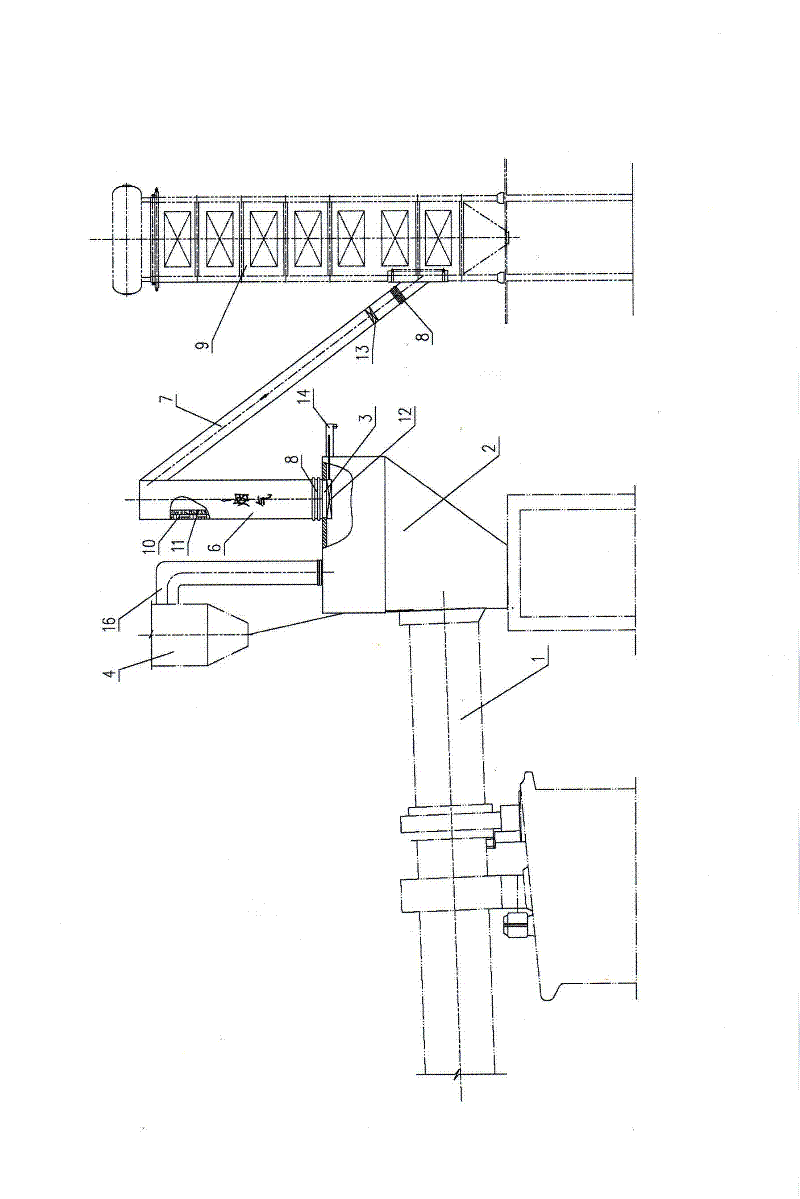

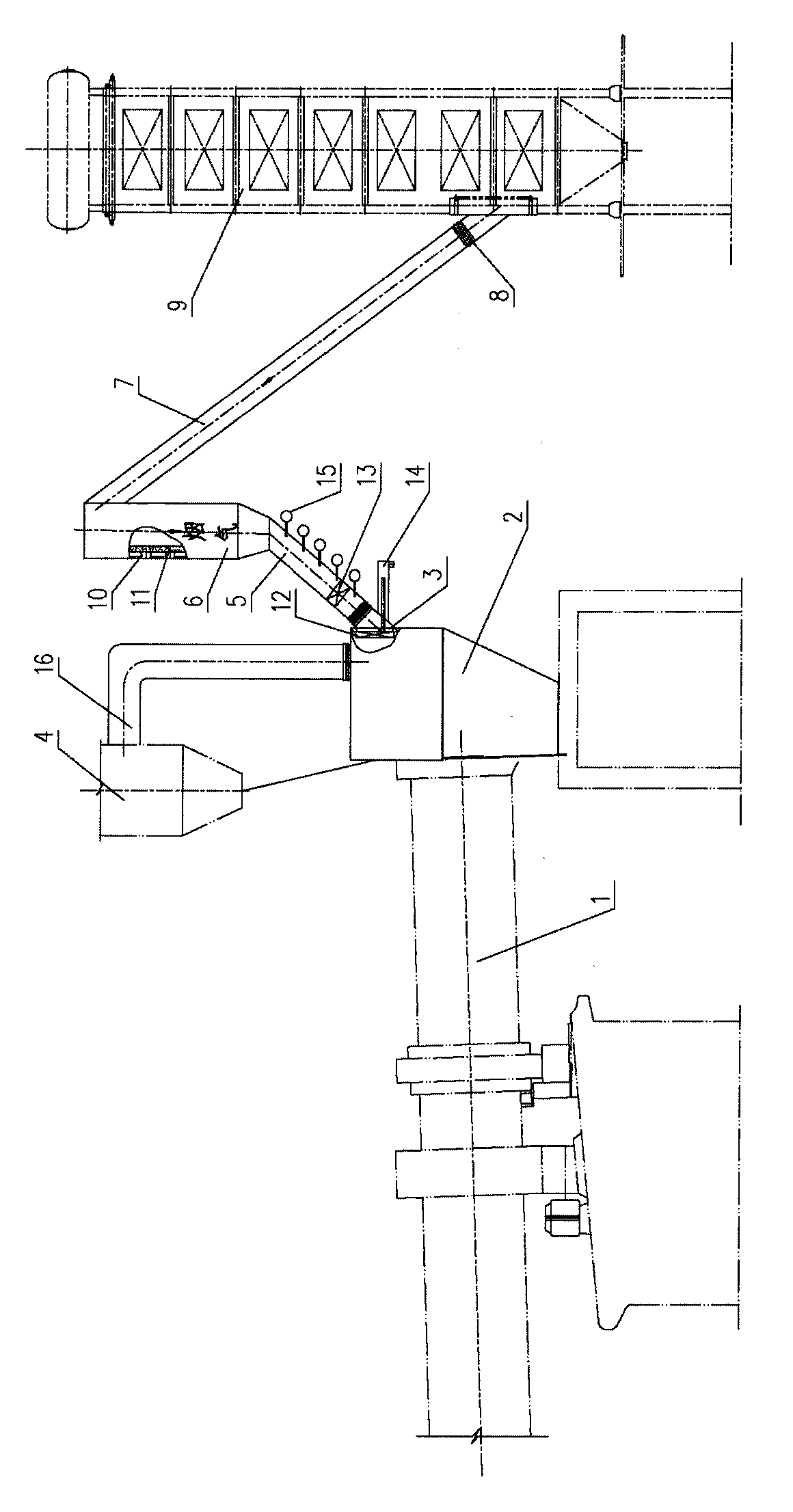

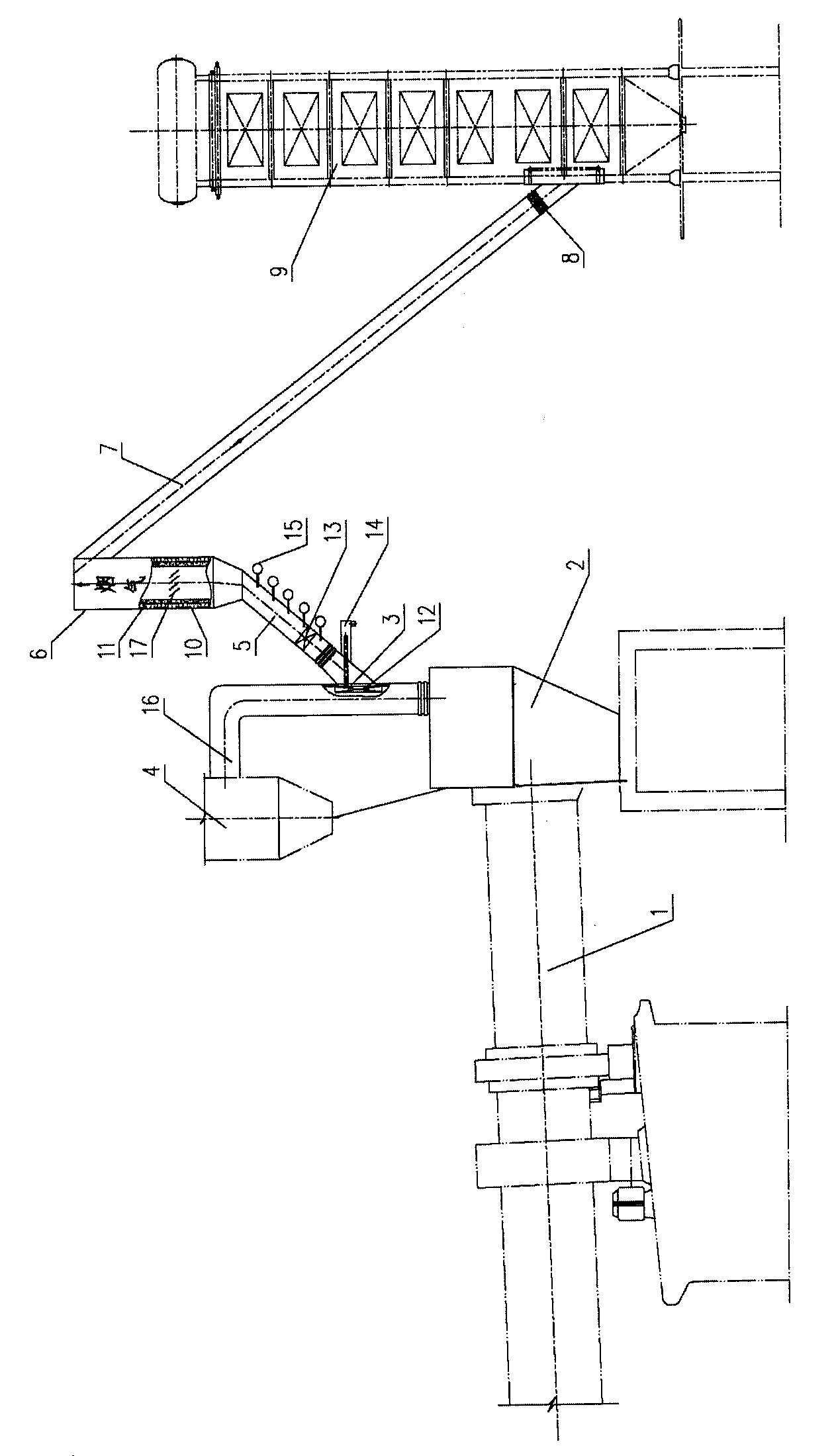

Air intake system for generating power by using cement kiln bypass flue gas waste heat

ActiveCN102401573ASolve the problem of easy crust cloggingAvoid enteringIncreasing energy efficiencyWaste heat treatmentThermodynamicsFlue gas

The invention discloses an air intake system for generating power by using cement kiln bypass flue gas waste heat. The air intake system comprises a rotary kiln, a kiln tail smoke chamber, a lifting flue, a preheater and a kiln tail bypass waste heat boiler; the side wall or the top of the kiln tail smoke chamber or the side wall of the lifting flue is provided with an air intake; the air intake is connected with a smoke inlet of the kiln tail bypass waste heat boiler through an air intake pipe; the air intake pipe consists of three sections of pipes, namely an air intake pipe I, an air intake pipe II and an air intake pipe III; the air intake pipe I is obliquely mounted upwards, the bottom end of the air intake pipe I is connected with the air intake, and the top end of the air intake pipe I is connected with the vertical air intake pipe III; the top end of the air intake pipe II is closed, and the side wall at the top end of the air intake pipe II is communicated with the air intake pipe III oblique downwards; and the bottom end of the air intake pipe III is communicated with the smoke inlet of the kiln tail bypass waste heat boiler. The air intake system can effectively solve the problem of ash blockage of a bypass air intake pipeline, and has the advantages of reasonable structure, convenience for assembly and disassembly, high efficiency, high safety, simple cleaning process, low ash blockage rate and the like.

Owner:大连九五高科新能源发展有限公司

Small hole rapid molding process

The invention discloses a small hole rapid molding process which comprises the following steps of: A. assembling a mould and installing with a material; B. punching a guide hole; C. grading; D. punching small holes; E. punching a small hole set; and F. sequentially circulating and repeating the step B, the step C and the step D until punching and cutting with the material for a metal to be processed is finished. When small hole processing is carried out by adopting the small hole rapid molding process, the mould is installed in a high-speed punch, working with more than 500 punching times perminute is carried out on the high-speed punch, and a product is once stamped and molded without needing secondary processing. The process has high production efficiency and low cost. Meanwhile, the invention also has the following characteristics that: the punching head of a convex mould is not easily broken and has long service life in the high-speed punching process.

Owner:CHENGDU HOMIN TECH

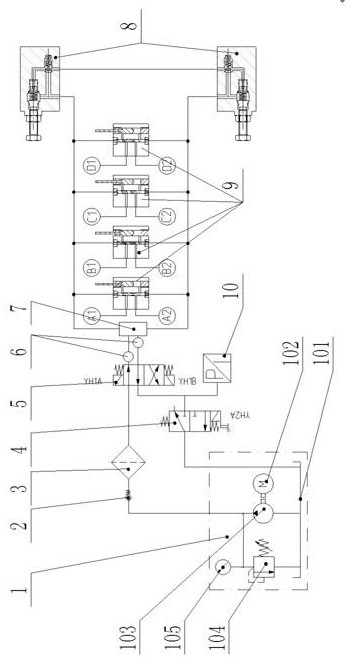

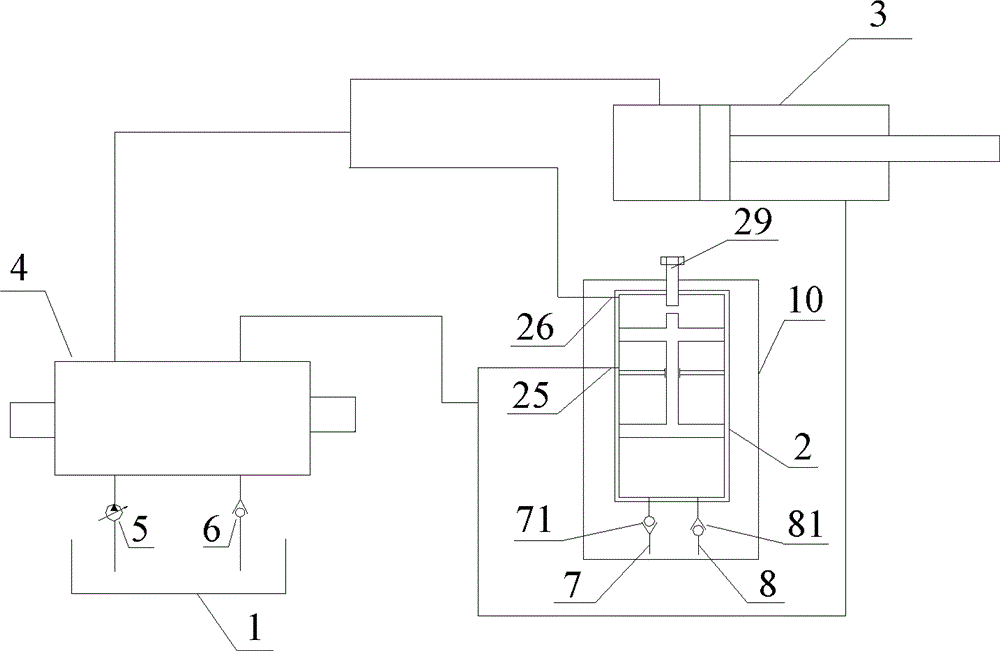

Dry oil centralized lubrication system

ActiveCN112303464AStructure diagramDistribution equipmentLubrication check valvesControl engineeringControl theory

The invention relates to a dry oil centralized lubrication system which comprises a pump station assembly, a one-way valve, a filter, a two-position three-way electromagnetic reversing valve, a two-position four-way electromagnetic reversing valve, flow meters, a rotary joint, one-way unloading valves, double-line distributors, a pressure relay and a PLC control cabinet for controlling a pump station; the pump station assembly, the one-way valve, the filter, the two-position three-way electromagnetic reversing valve, the two-position four-way electromagnetic reversing valve and the flow metersare installed around a winding drum, and the rotary joint is installed at the tail end of the winding drum; and the two one-way unloading valves and the plurality of double-line distributors are installed in the winding drum which rotates at a high speed. According to the technical scheme, by designing the minimum number of pipelines, the one-way unloading valve is additionally arranged behind the last distributor, two cavities of the distributor are connected, although a pressure operating valve is installed beside the pump station, the pressure operating valve is actually located at the tail end of the pipeline, closed control over the system is achieved, and the phenomenon of dead oil in the dry oil system is eliminated.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Water cleaning and heating device free from secondary pollution

InactiveCN1248635CSolve the impactSolve the problem of connecting the atmosphereWater/sewage treatment by irradiationBeverage vesselsAtmospheric airEngineering

The clean water heater which is connected with clean water source, can be used for providing cold and hot drinking water instantaneously and conveniently and does not produce secondary pollution includes a shell body with cold water tap and hot water tap, clean water intake tube with electromagnetic valve and heating internal container with temp. controller and electroheating wire, in which the cold water tap is directly connected with clean water intake tube, and the hot water tap is communicated with heating internal container, and said heating internal container is communicated with clean water intake tube by means of electromagnetic valve.

Owner:蒋仕美 +1

Aperture punching and forming integrated grading die

The invention discloses an aperture punching and forming integrated grading die. The grading die includes an upper die body, a lower die body, a convex die body, a concave die body and a secondary precise guide mechanism; the convex die body is arranged in the upper die body; the concave die body is arranged in the lower die body; and the upper die body and the lower die body are connected together through the secondary precise guide mechanism. The aperture punching and forming integrated grading die can perform punching for 500 times per minute on a high speed punching machine, can allow once punch-forming of products without secondary machining, is high in production efficiency in aperture machining, and is low in cost; and in a high speed punching process, a small punch will not break off, and the service life is long.

Owner:唐小琴

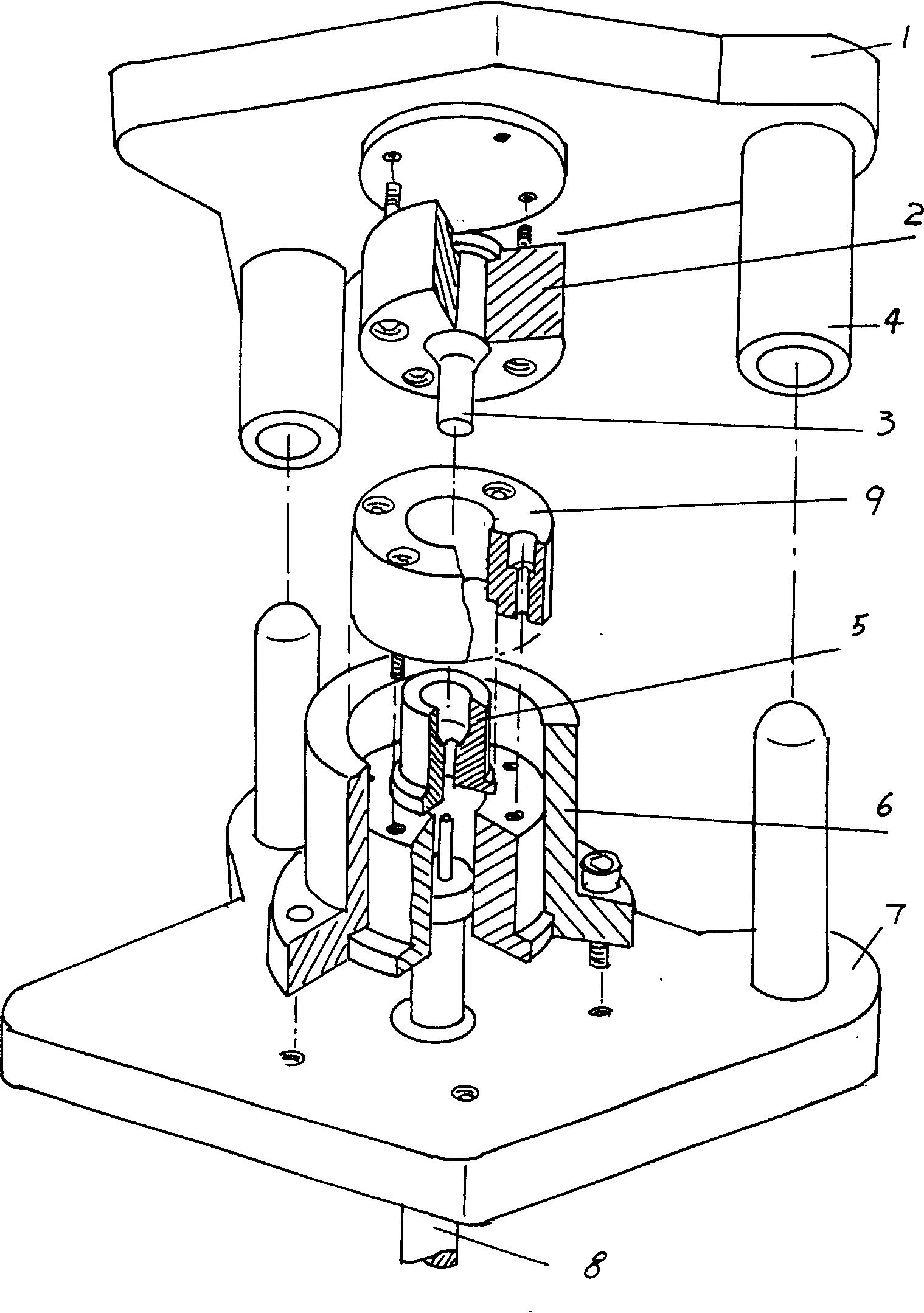

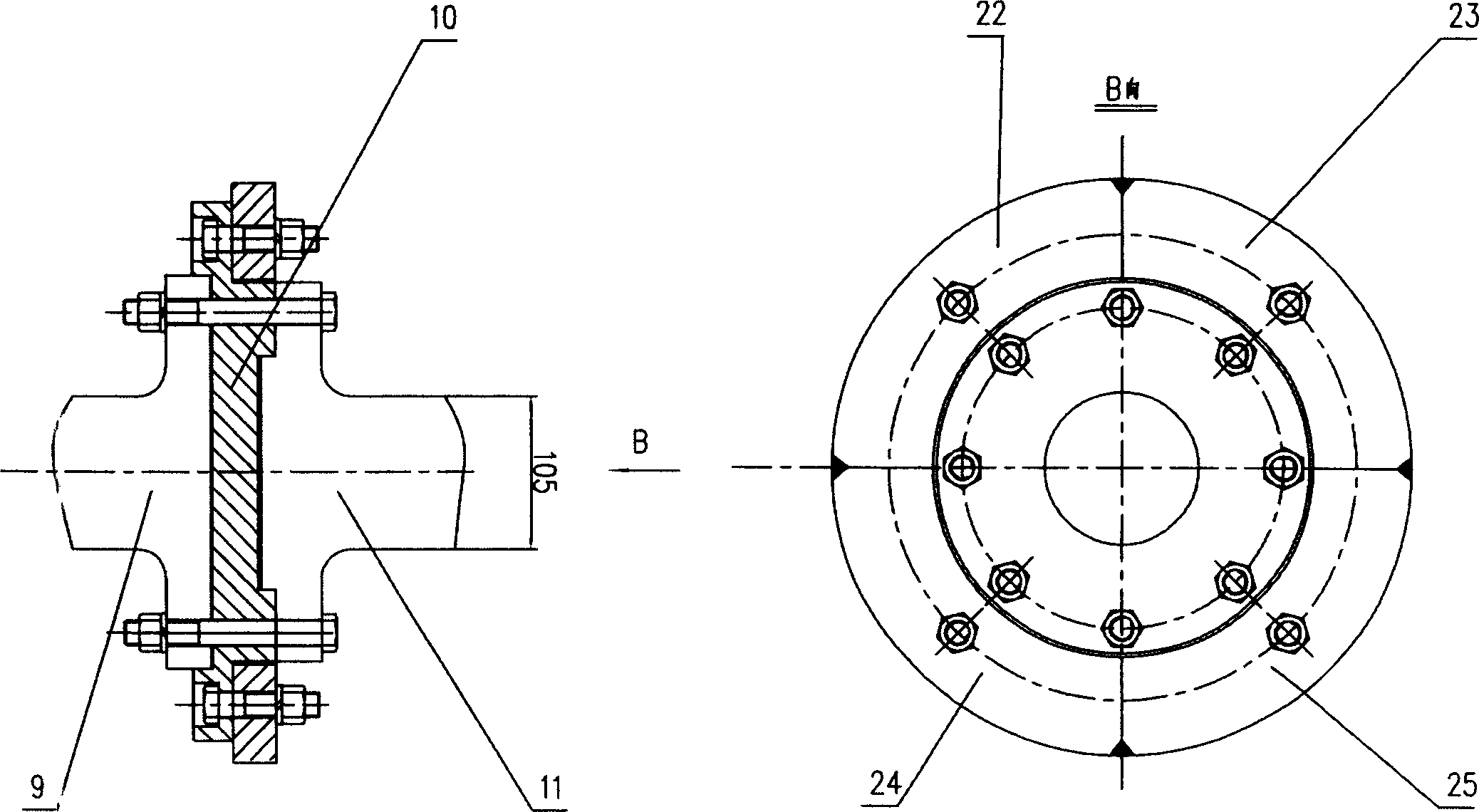

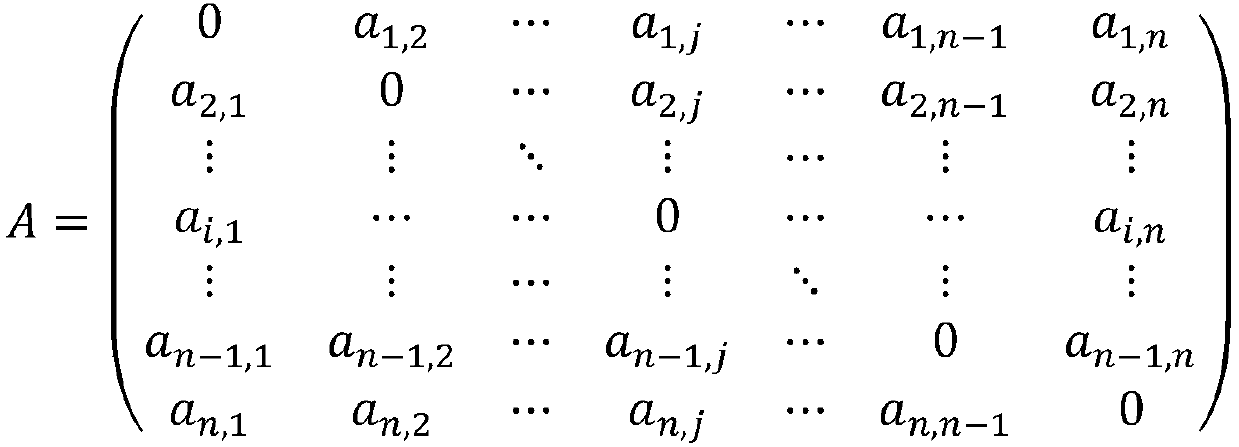

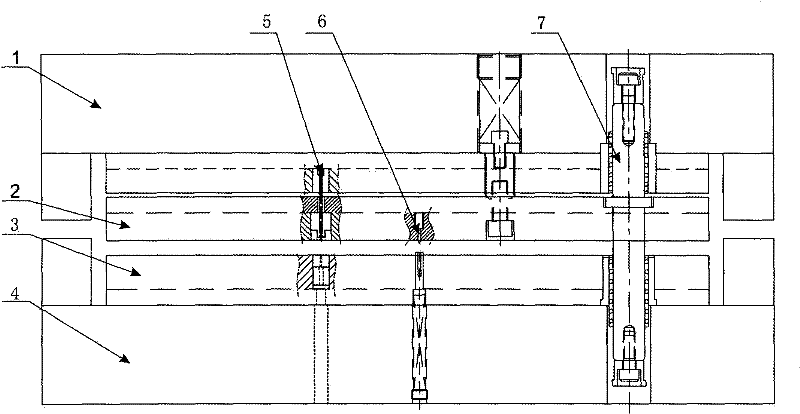

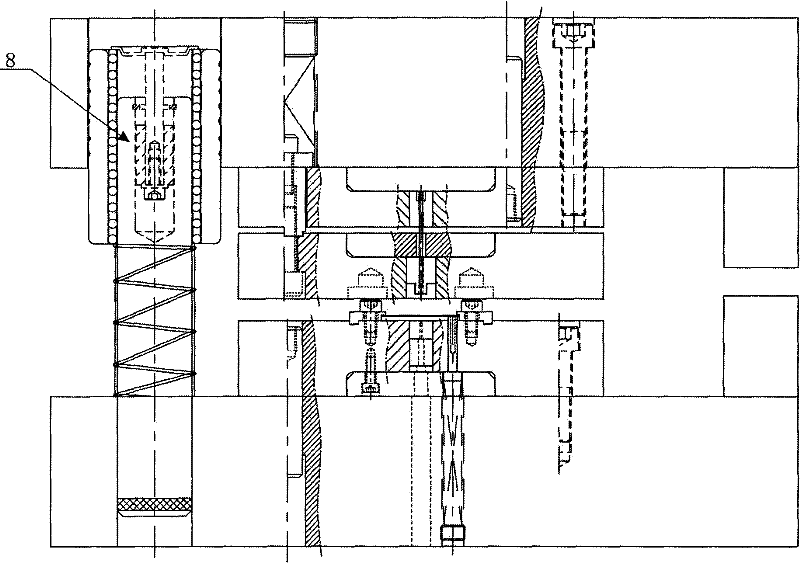

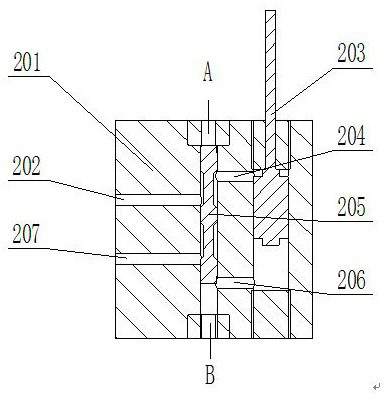

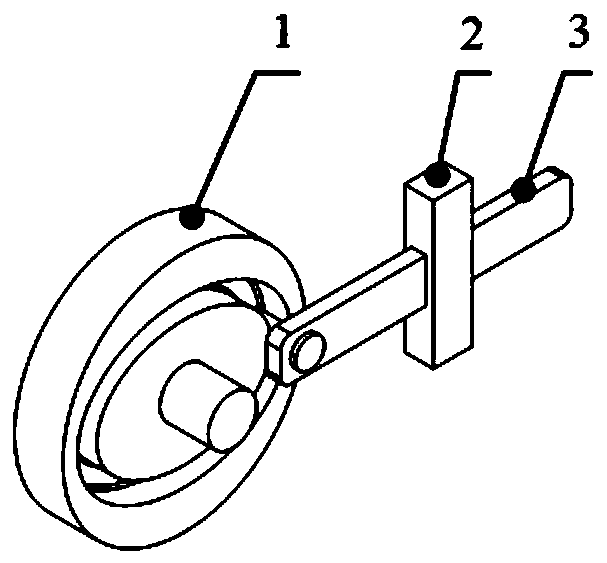

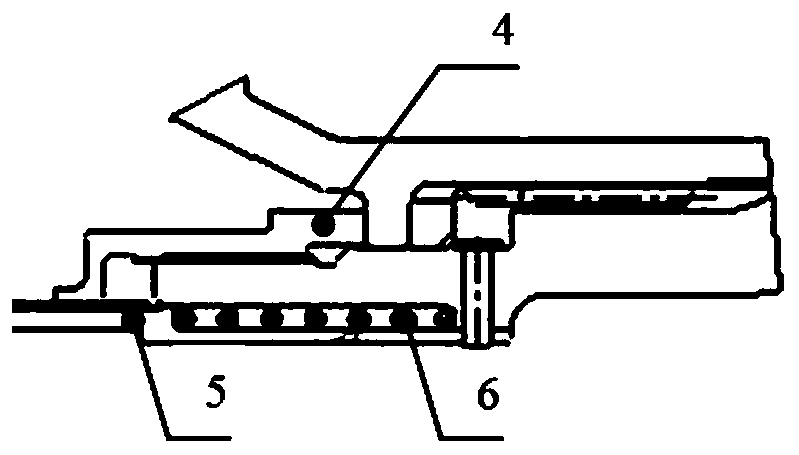

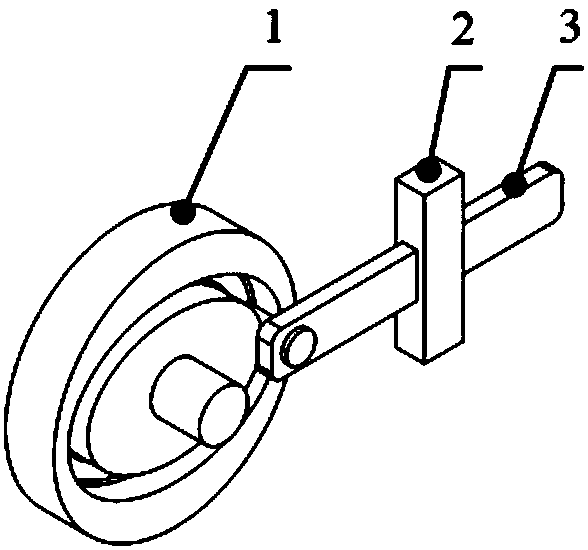

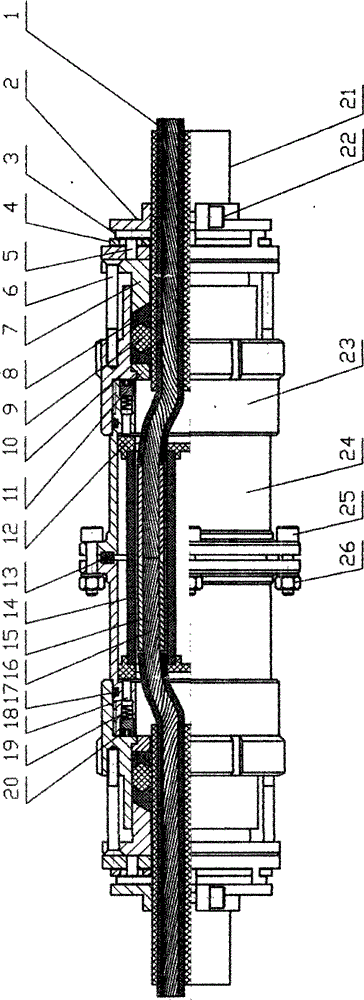

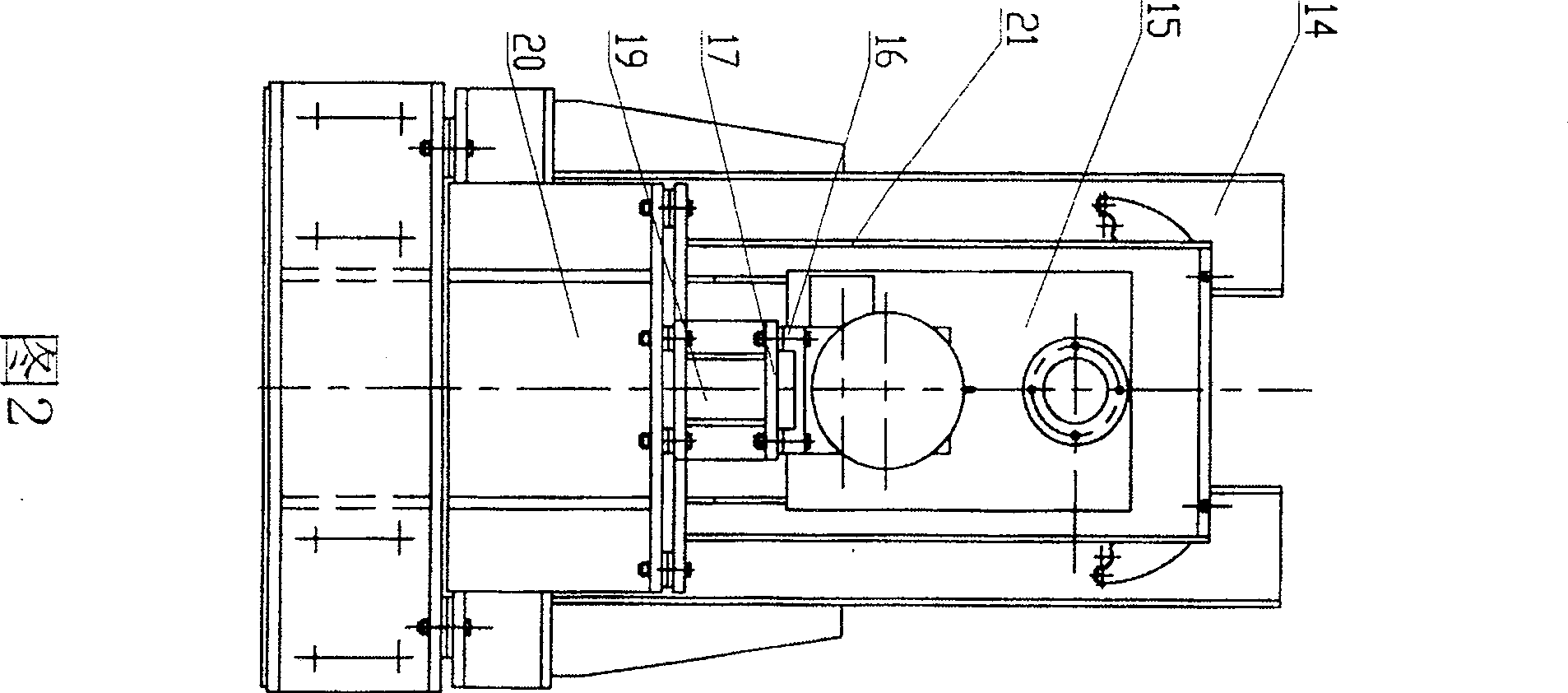

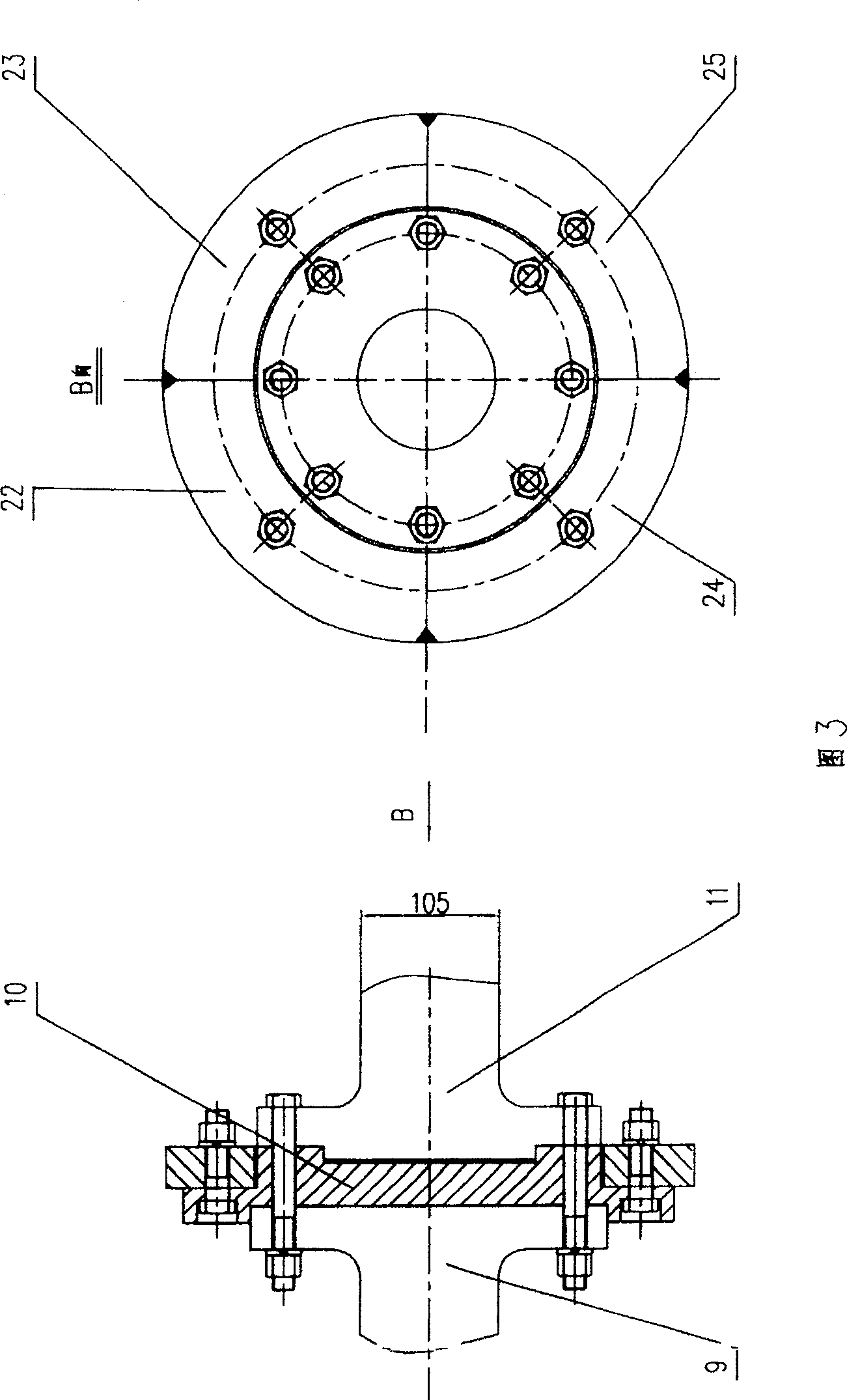

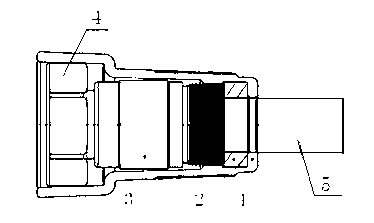

An assembly device and method for an aeroengine spline sleeve gear coupling

ActiveCN108177127BAvoid destructionQuickly complete the assembly processMetal-working hand toolsAviationCoupling

The invention relates to an assembling device and method of a splined sleeve gear coupling of an aircraft engine. The structure of the device is shown in fig.1. The device mainly comprises a driving assembly (1), a housing assembly (2) and a spring bolt assembly (3). With the adoption of the device, the splined sleeve gear coupling of the aircraft engine can be safely and reliably assembled, and the engine is prevented from damage caused by assembling the structure through a general device; a device for indicating the rotating angle of a shaft end nut (4) is provided. The invention also relates to a method for assembling the splined sleeve gear coupling. With the adoption of the device and method, the assembling position of the shaft end nut (4) can be accurately determined; an inner bushing (5) spline can be smoothly sprung out from an inner spline of the shaft end nut (4) in one time. With the adoption of the method, the assembling efficiency of the splined sleeve gear coupling can be improved, and the assembling circle is reduced; and meanwhile the engine assembling quality is ensured; and the quality risk of damage of parts and assemblies of the engine in the splined sleeve gear coupling assembling process can be obviously reduced.

Owner:AECC SICHUAN GAS TURBINE RES INST

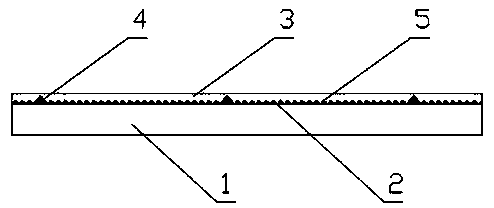

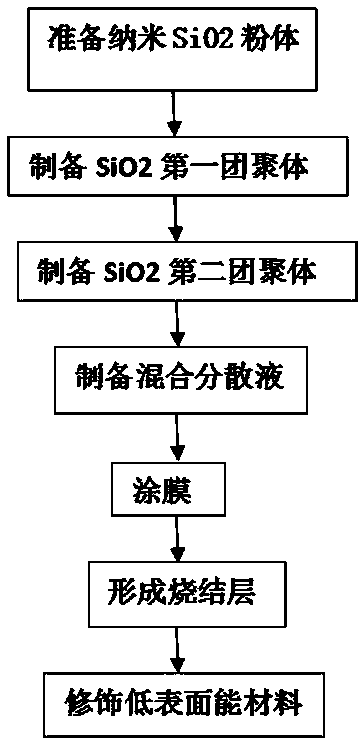

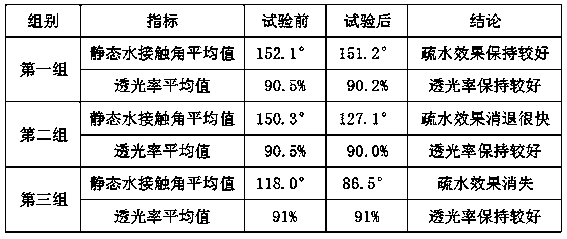

Scratch-resistant hydrophobic glass and preparation method thereof

The invention relates to scratch-resistant hydrophobic glass and a preparation method thereof. The scratch-resistant hydrophobic glass comprises a glass substrate (1), and is characterized in that a sintering layer (2) and a hydrophobic film (3) are arranged on the glass substrate (1). The preparation method comprises the following steps: a, preparing an SiO2 first aggregate; b, preparing an SiO2second aggregate dispersing agent; c, adding the SiO2 first aggregate into the SiO2 second aggregate dispersing agent, adding a silane coupling agent, and stirring to obtain an SiO2 mixed dispersing agent; d, smearing the SiO2 mixed dispersing agent on the surface of the glass substrate; e, heating the glass substrate to form the sintering layer; and f, smearing a low surface energy material on the sintering layer for solidification. The scratch-resistant hydrophobic glass has the advantages that firstly, the prepared sintering layer is stable in structure and unlikely to be separated, and lasting protection can be realized; secondly, through the synergistic effect of the SiO2 first aggregate and second aggregate, the stress is reduced through the hydrophobic film, the abrasion is reduced,the adhesive force is improved, the deformation and movement of the film are blocked, and the separation of the hydrophobic film from the surface of the glass and the destroy of a coarse structure are blocked effectively; and thirdly, the hydrophobic glass has relatively high visible light transmittance.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Assembling device and method of splined sleeve gear coupling of aircraft engine

ActiveCN108177127AAvoid destructionQuickly complete the assembly processMetal-working hand toolsAviationCoupling

The invention relates to an assembling device and method of a splined sleeve gear coupling of an aircraft engine. The structure of the device is shown in fig.1. The device mainly comprises a driving assembly (1), a housing assembly (2) and a spring bolt assembly (3). With the adoption of the device, the splined sleeve gear coupling of the aircraft engine can be safely and reliably assembled, and the engine is prevented from damage caused by assembling the structure through a general device; a device for indicating the rotating angle of a shaft end nut (4) is provided. The invention also relates to a method for assembling the splined sleeve gear coupling. With the adoption of the device and method, the assembling position of the shaft end nut (4) can be accurately determined; an inner bushing (5) spline can be smoothly sprung out from an inner spline of the shaft end nut (4) in one time. With the adoption of the method, the assembling efficiency of the splined sleeve gear coupling can be improved, and the assembling circle is reduced; and meanwhile the engine assembling quality is ensured; and the quality risk of damage of parts and assemblies of the engine in the splined sleeve gear coupling assembling process can be obviously reduced.

Owner:AECC SICHUAN GAS TURBINE RES INST

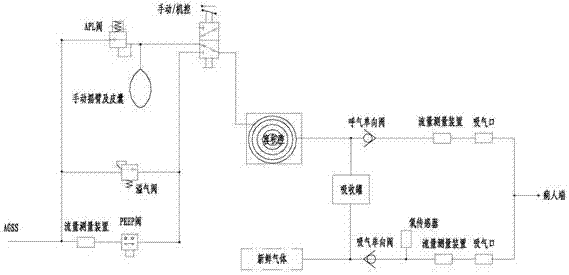

Integrated anesthesia respiratory system

An integrated anesthesia breathing system, including a lime tank, a bypass mechanism, an adapter cover, an air circuit cover, a lower seal, an inspiratory joint, a bladder joint, an exhalation joint, the middle of the air circuit, an inspiratory one-way valve, It is composed of an exhalation check valve, an air path cover, a pressure regulating valve, a manual-automatic transfer switch, an upper seal of the air path, and a ventilator intake module. The main air path is directly installed in the valve seat and fixed by screw connections, or Through the push-in method, it contains 11 push-in connectors, and each push-in connector is sealed by an O-ring.

Owner:BEIJING AEROSPACE CHANGFENG CO LTD

Air intake system for generating power by using cement kiln bypass flue gas waste heat

ActiveCN102401573BSolve the problem of easy crust cloggingAvoid enteringIncreasing energy efficiencyWaste heat treatmentThermodynamicsFlue gas

The invention discloses an air intake system for generating power by using cement kiln bypass flue gas waste heat. The air intake system comprises a rotary kiln, a kiln tail smoke chamber, a lifting flue, a preheater and a kiln tail bypass waste heat boiler; the side wall or the top of the kiln tail smoke chamber or the side wall of the lifting flue is provided with an air intake; the air intake is connected with a smoke inlet of the kiln tail bypass waste heat boiler through an air intake pipe; the air intake pipe consists of three sections of pipes, namely an air intake pipe I, an air intake pipe II and an air intake pipe III; the air intake pipe I is obliquely mounted upwards, the bottom end of the air intake pipe I is connected with the air intake, and the top end of the air intake pipe I is connected with the vertical air intake pipe III; the top end of the air intake pipe II is closed, and the side wall at the top end of the air intake pipe II is communicated with the air intake pipe III oblique downwards; and the bottom end of the air intake pipe III is communicated with the smoke inlet of the kiln tail bypass waste heat boiler. The air intake system can effectively solve the problem of ash blockage of a bypass air intake pipeline, and has the advantages of reasonable structure, convenience for assembly and disassembly, high efficiency, high safety, simple cleaning process, low ash blockage rate and the like.

Owner:大连九五高科新能源发展有限公司

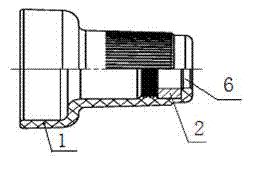

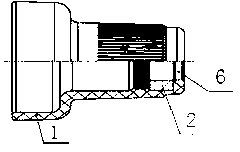

Stainless steel made large-diameter cable waterproof connector

ActiveCN101071943BFill the gap in the marketStructure diagramCable junctionsEngineeringFire retardant

Owner:GUANGZHOU RMEECO WATERPROOF & APPLIANCES CO LTD

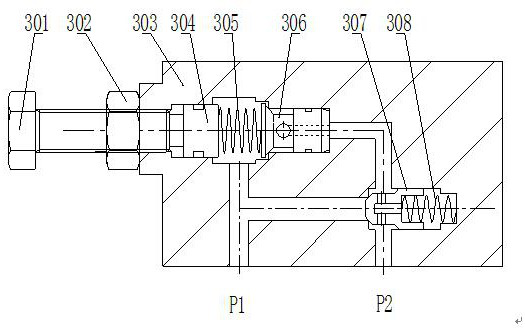

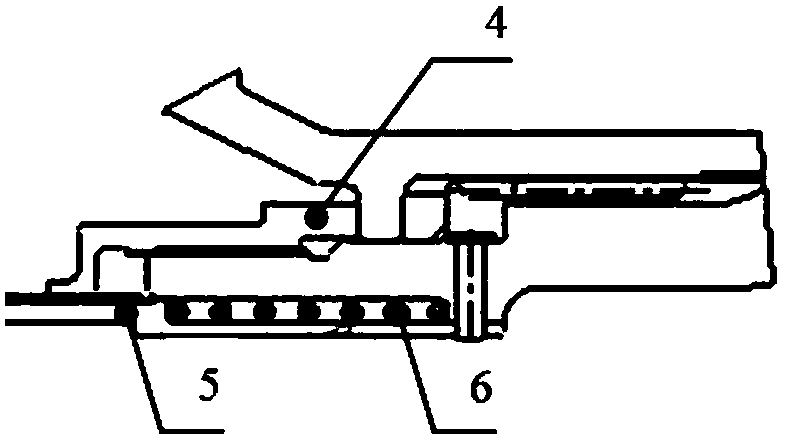

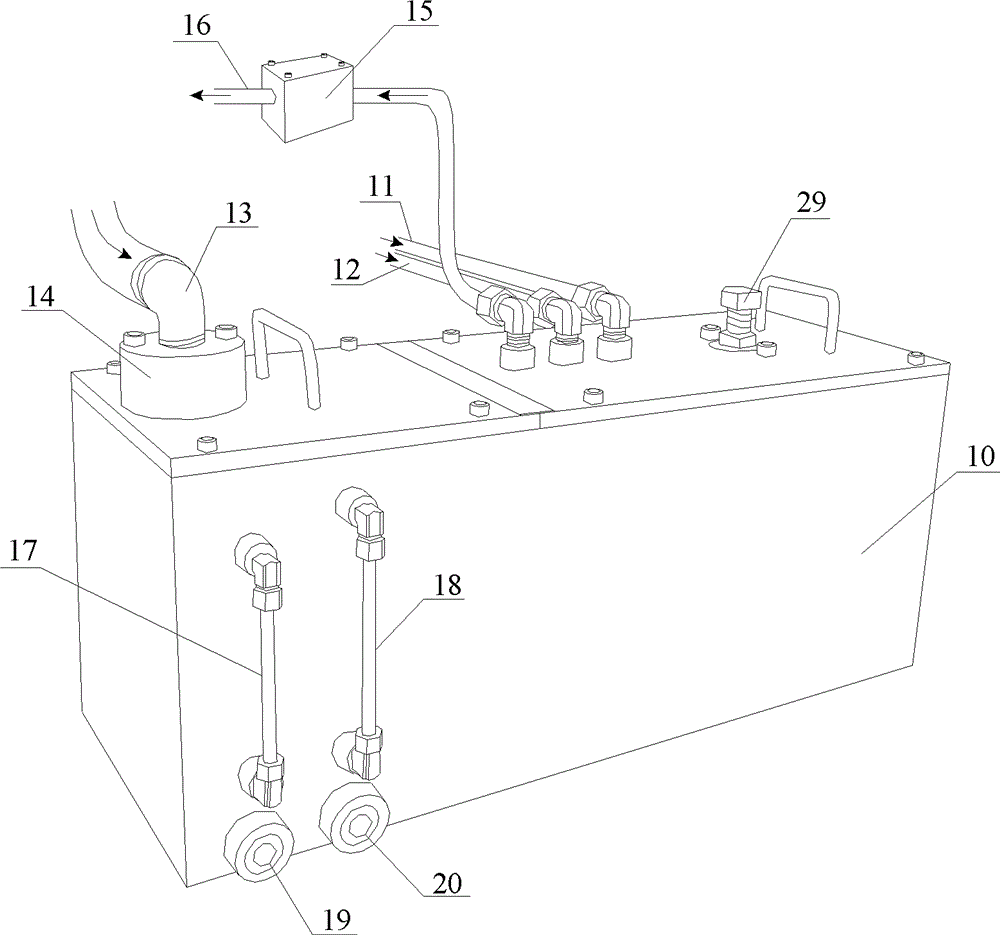

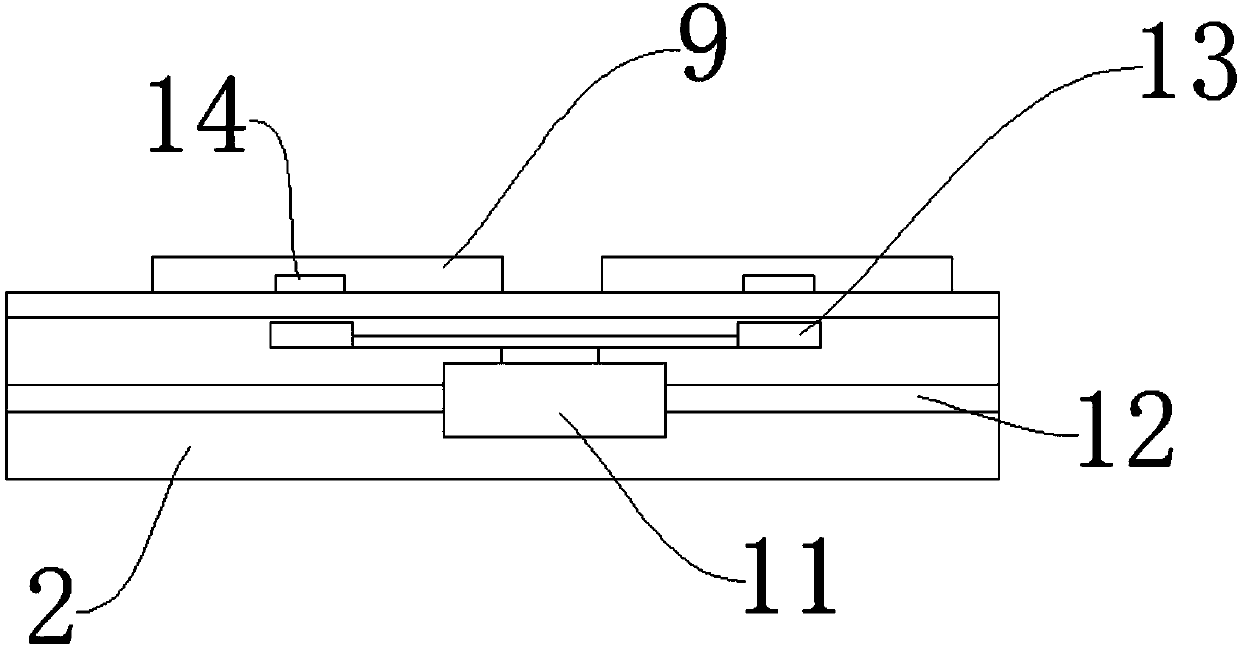

Thin oil lubricating and injecting system without motor to drive in injection molding machine and thin oil lubricating and injecting device

The invention provides a thin oil lubricating and injecting system without a motor to drive in an injection molding machine and a thin oil lubricating and injecting device used for the system. According to the thin oil lubricating and injecting system, a lubricant oil injecting pump is positioned in a lubricant oil storage tank; the lubricant oil injecting pump and an opening and closing mold oil cylinder are connected in parallel in an opening and closing mold hydraulic oil line of the injection molding machine; high pressure generated at the moment that the mold is opened by the injection molding machine is utilized to suck lubricant oil stored in the oil storage tank to the lubricant oil injecting pump; and then, high pressure at the moment that the mold is closed by the injection molding machine is utilized to discharge the lubricant oil in the lubricant oil injecting pump to an elbow mold closing mechanism of the injection molding machine, so that the elbow mold closing mechanism of the injection molding machine can be periodically lubricated when the mold is closed every time. According to the invention, no external motor is arranged in the thin oil lubricating and injecting system, the service life of oiling equipment is prolonged, and the energy conservation and consumption reduction are also realized at the same time.

Owner:上海川口机械有限公司

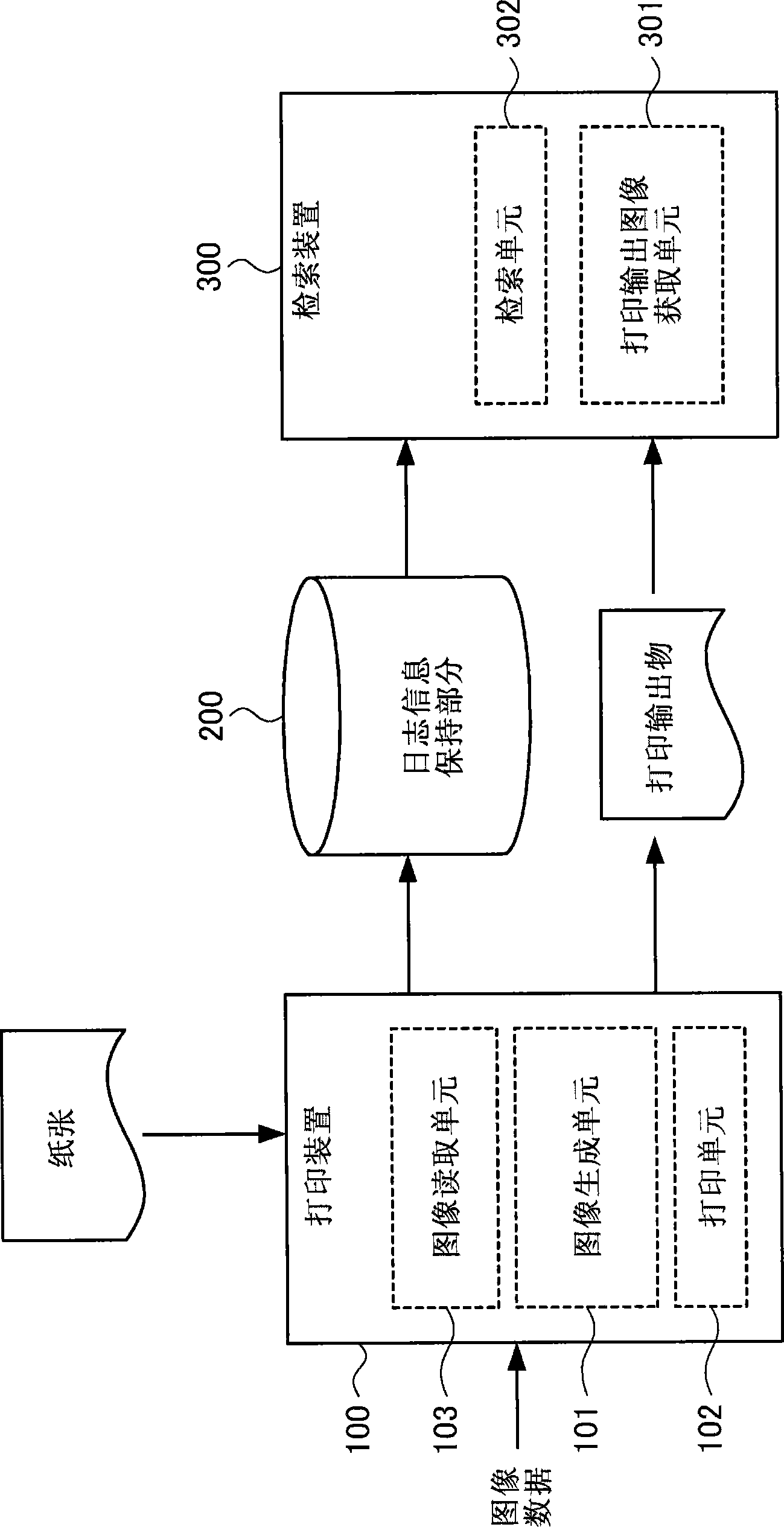

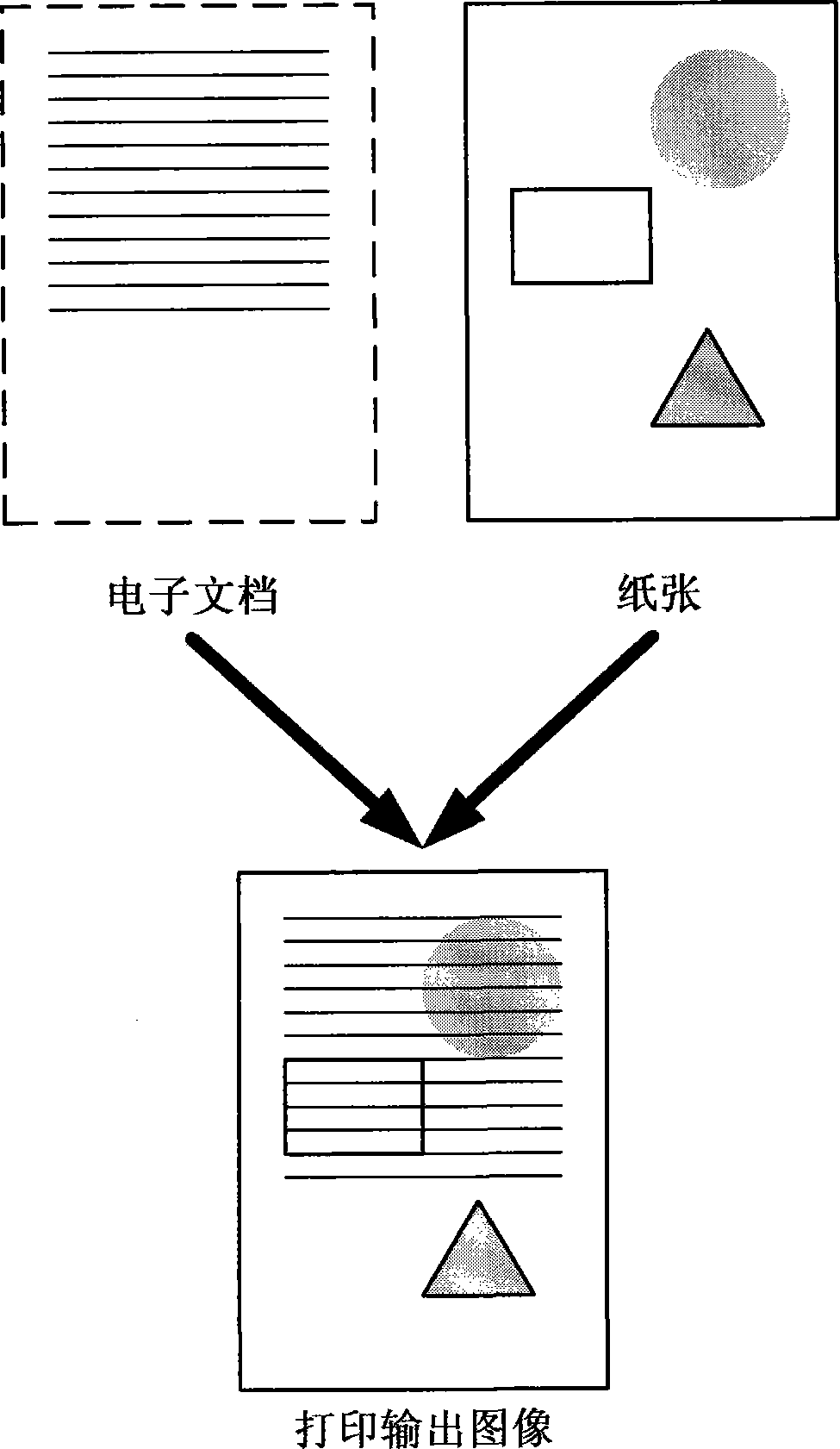

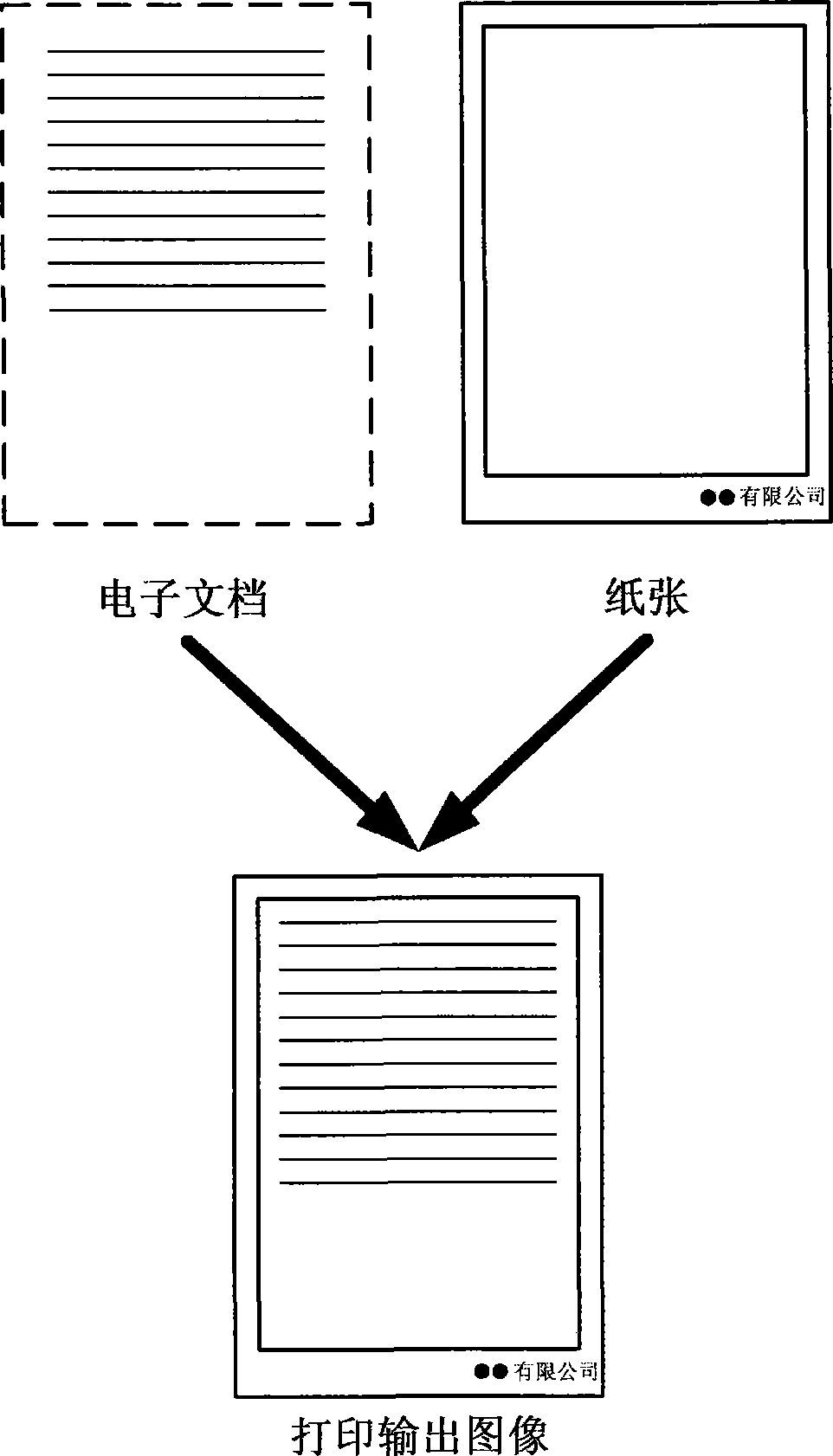

Document processing system, search apparatus, information searching method and document processing method

ActiveCN101841613BStructure diagramSpecial data processing applicationsPictoral communicationComputer graphics (images)Engineering

The document processing system is provided with: a printing unit that prints a document image on a medium; an image reading unit that performs image reading on the medium; a holding unit that holds history information on processing performed by the printing unit; and a search unit that searches the history information held by the holding unit on the basis of an image of a printout which is the medium with the document image printed on the medium by the printing unit. The search unit determines similarity between the image of the printout and a synthetic image in which the document image is synthesized with an image of the medium read by the image reading unit, and searches for history information on processing performed for the printout on the basis of a result of the determination.

Owner:FUJIFILM BUSINESS INNOVATION CORP

High temperature sliding wear and thermal contact fatigue testing machine for material

InactiveCN100487418CImprove efficiencyLow costUsing mechanical meansInvestigating abrasion/wear resistanceHydraulic pumpPressure sense

Owner:UNIV OF SCI & TECH BEIJING

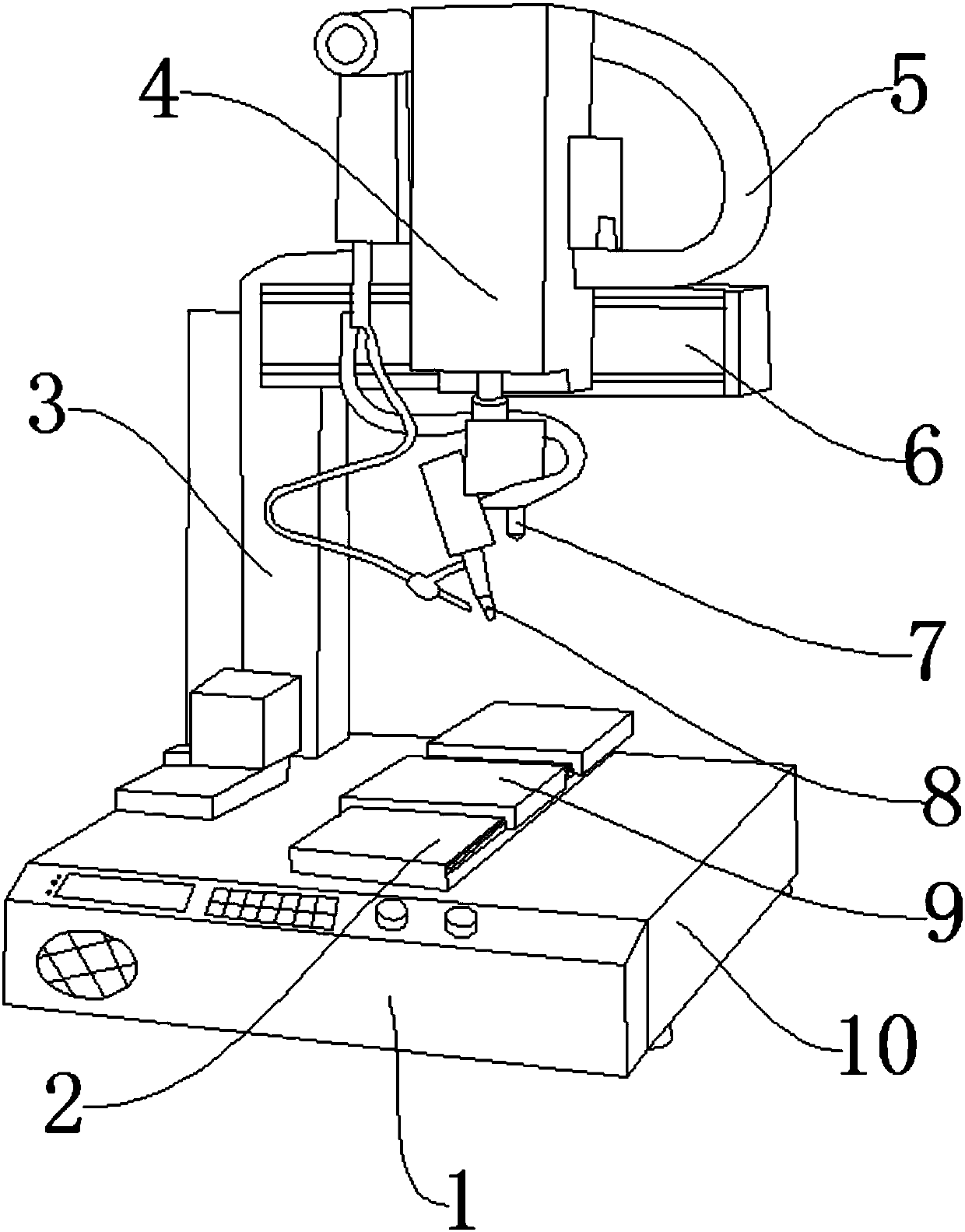

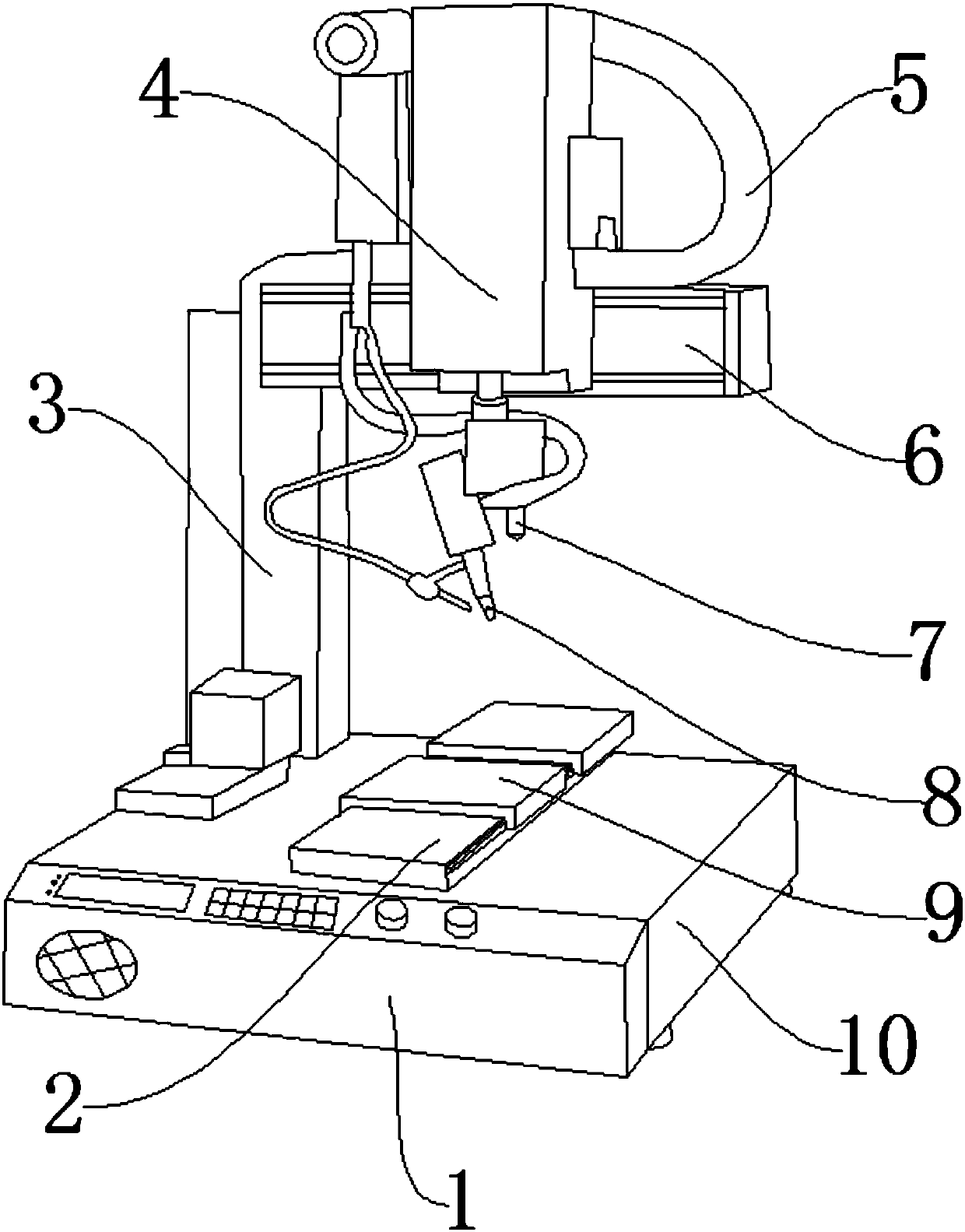

Rapid soldering device

InactiveCN109909572AProtect your healthImprove efficiencyMetal working apparatusSoldering auxillary devicesEngineeringInductor

The invention discloses a rapid soldering device. The rapid soldering device comprises a support table, and a conveying belt. An adjuster is arranged on the front face of the support table, an ejecting base is arranged on the support table, a rail is arranged in the base, a direct-current power source is arranged on the rail, a lower magnet is arranged above the direct-current power source, an operation table is arranged in the ejecting base, an upper magnet is arranged in the operation table, an ejecting column is arranged on one side of the ejecting base, an insulation belt is arranged on the ejecting column, a conveying belt is arranged on the insulation belt, an insulation belt is arranged on the rear portion of the conveying belt, a welding gun is arranged below the conveying belt, and a temperature inductor is arranged beside the welding gun. The device has the beneficial effects that the machine replaces manual work, efficiency is improved, and body health of a person is protected.

Owner:西安天恩电子科技有限公司

Cable connector

InactiveCN102832494ASimple structureIngenious designCouplings bases/casesMulticonductor cable end piecesEngineeringAqueous solution

The invention relates to the technical field of cable connectors, in particular to a cable connector which comprises a metal housing and a barrel, and is also provided with a protection housing, wherein the protection housing is sleeved on the metal housing and the barrel, and a sealing ring is embedded in a joint of the tail end of the protection housing and the metal housing. The invention better solves the problem of corrosion of a water solution containing acidic and alkaline materials to the connector in an outdoor antenna feed system, is simple in structure, is low in price, has higher practical value, and can be largely popularized and used.

Owner:CHANGZHOU AMPHENOL FUYANG COMM EQUIP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com