Thin oil lubricating and injecting system without motor to drive in injection molding machine and thin oil lubricating and injecting device

A thin oil lubrication and oil injection device technology is applied in the thin oil lubrication oil injection system of injection molding machine, the thin oil lubrication oil injection device, and the lubrication oil injection system field, which can solve the problem of increasing energy consumption, insufficient lubrication of the elbow contact surface, and low oil injection pressure. and other problems to achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

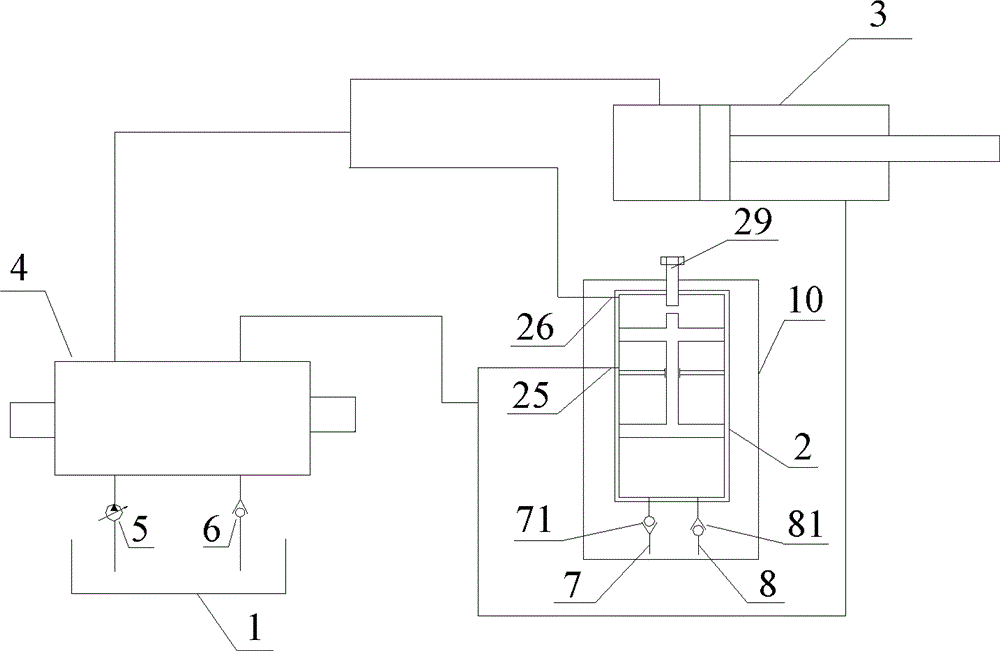

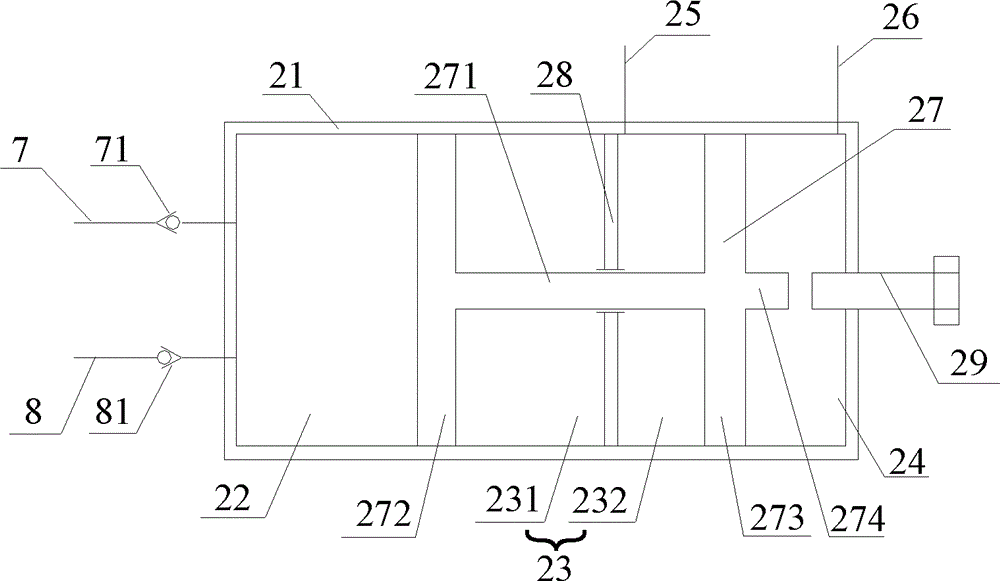

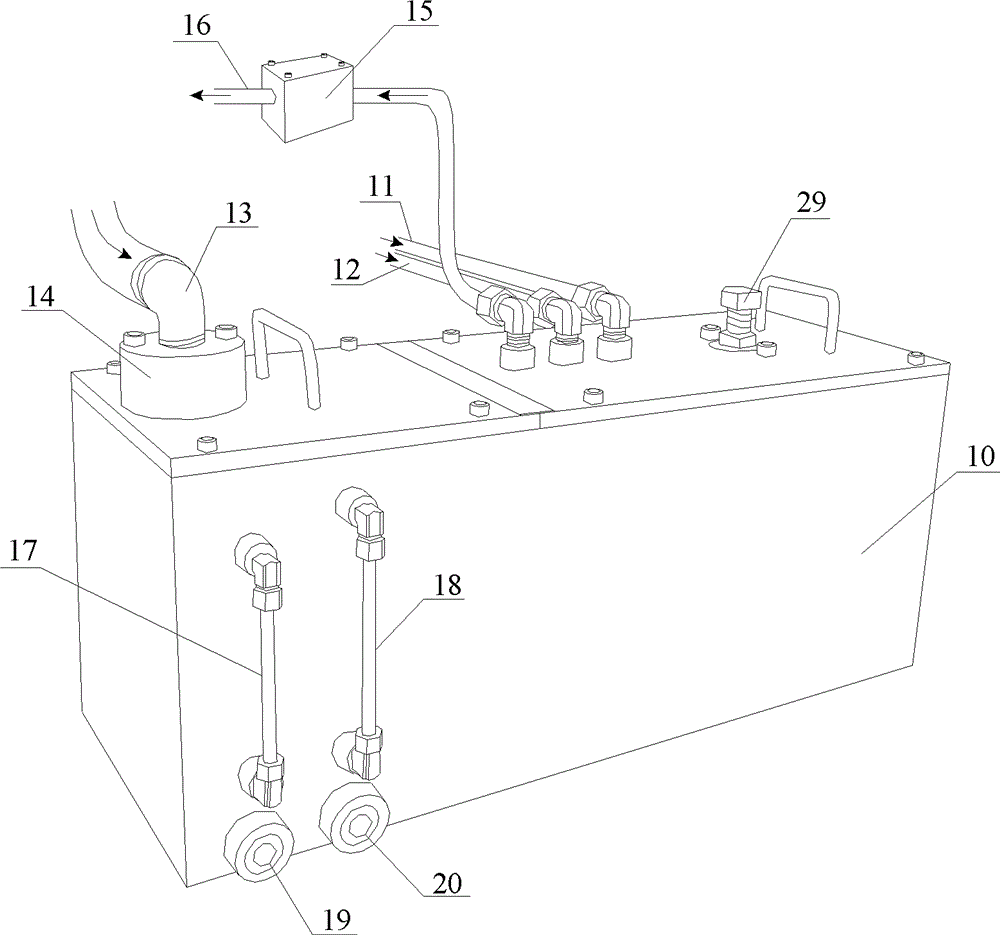

[0028] Such as figure 1 As shown, in order to realize the periodic lubrication of the toggle mold clamping mechanism by the lubricating system of the injection molding machine, the present invention provides a thin-oil lubricating oil injection system for the injection molding machine that does not need to be driven by a motor. The system mainly includes hydraulic oil tank 1, lubricating oil injection pump 2, mold opening and closing cylinder 3, mold opening and closing valve 4, oil pump 5, check valve 6 and lubricating oil storage tank 10.

[0029] Wherein, the oil outlet end of the hydraulic oil tank 1 is connected to the inlet end of the mold opening and closing cylinder 3 through the oil pipeline, and the outlet end of the mold opening and closing cylinder 3 is connected to the oil inlet end of the hydraulic oil tank 1 through the oil pipeline, forming a Injection molding machine mold opening and closing hydraulic oil circuit. A switch mold valve 4 is installed on the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com