High temperature sliding wear and thermal contact fatigue testing machine for material

A material testing machine and thermal contact technology, applied in the direction of analyzing materials, testing wear resistance, using mechanical devices, etc., can solve the problems of difficulty in simulating production conditions, short length of rolling pieces, etc., and achieve high reliability and low cost of equipment operation. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

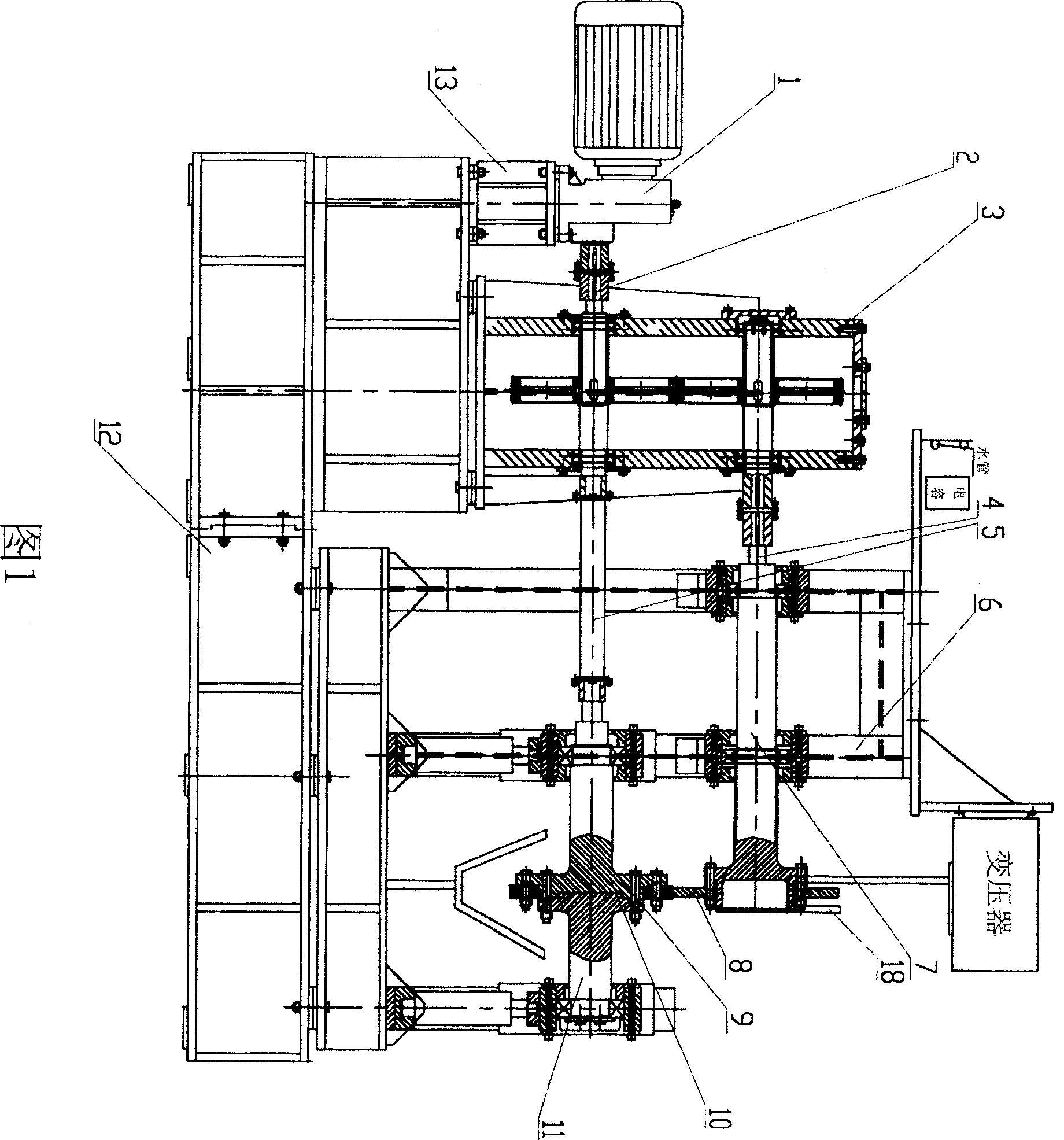

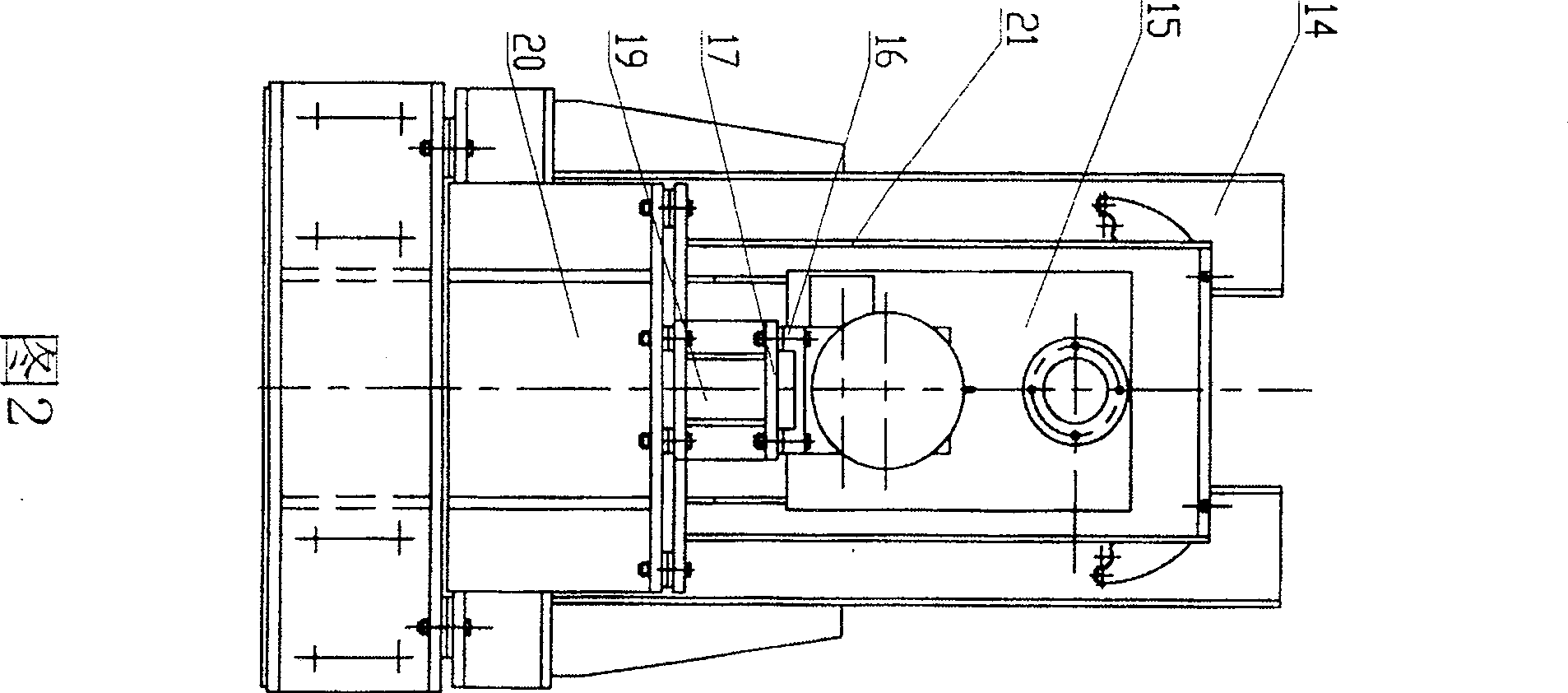

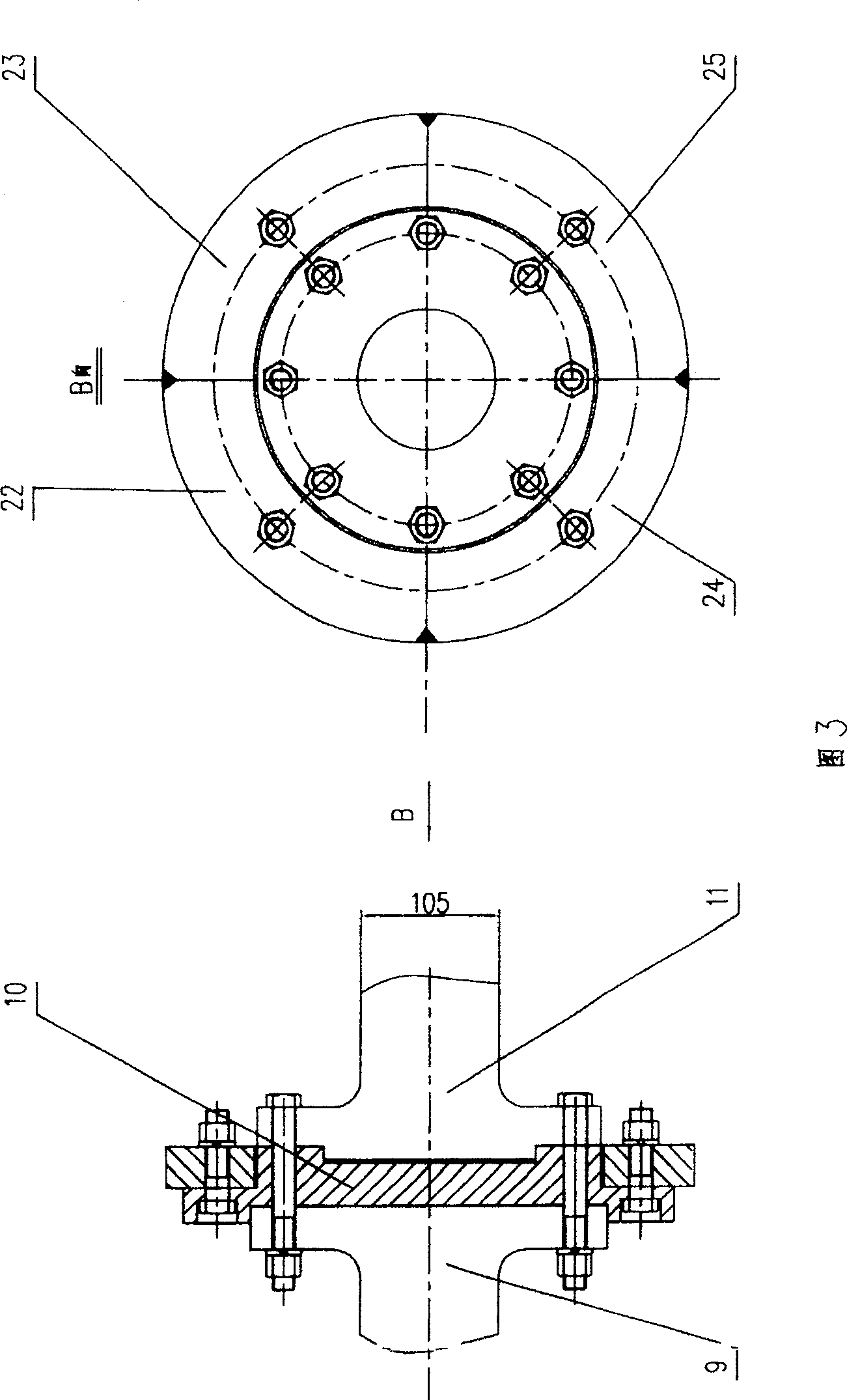

[0021] The high-temperature sliding wear and thermal contact fatigue material testing machine includes a geared motor 1, a support 13, a coupling 2, a distribution gearbox 3, a universal joint shaft 4, 5, a frame 14, an upper friction pair system 6, and a lower friction pair System lifting hydraulic cylinder 19, hydraulic cylinder connecting seat 17, hydraulic cylinder base 20, base 12, induction heating coil 18, upper friction pair system including rotary shaft 7, bearing seat 15, pressure plate 21, upper friction wheel 8, lower friction pair system It consists of a left rotary shaft 9, a chuck 10, a right rotary shaft 11, a bearing seat 16, a lower friction wheel 22, a coupling bolt 23, and a positioning plate 24. The hydraulic system includes electromagnets 26, 27 for electromagnetic reversing, and pressure gauge The electric contact relay 28, the reduction motor 1 is installed on the base 12 through the support 13, the distribution gearbox 3 is installed on the base 12, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com