High gradient biregion heating directional solidification device

A directional solidification and high-gradient technology, applied in self-solidification, crystal growth, chemical instruments and methods, etc., can solve problems such as low temperature gradient, small speed range, and large system, and achieve the effect of preventing reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

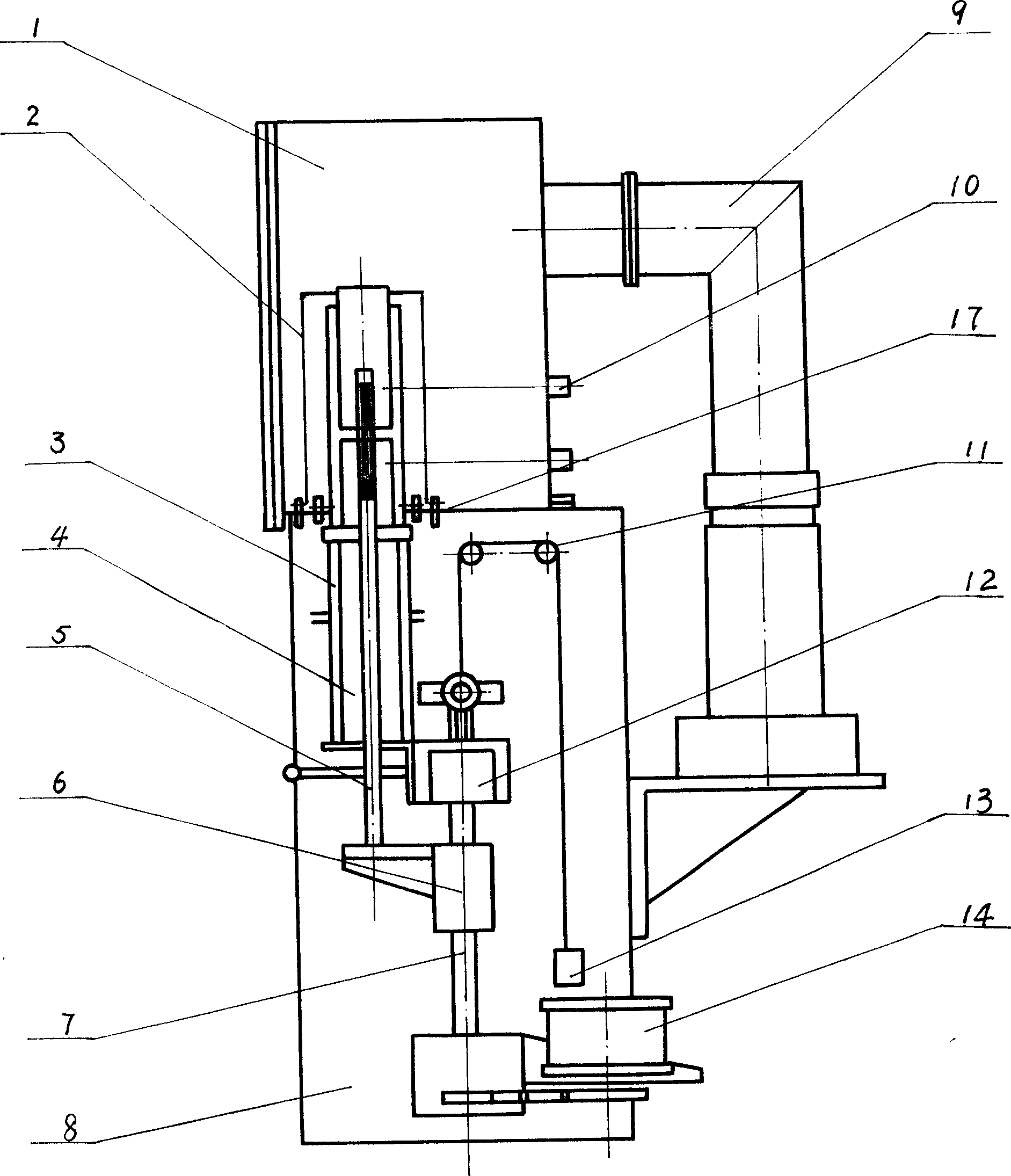

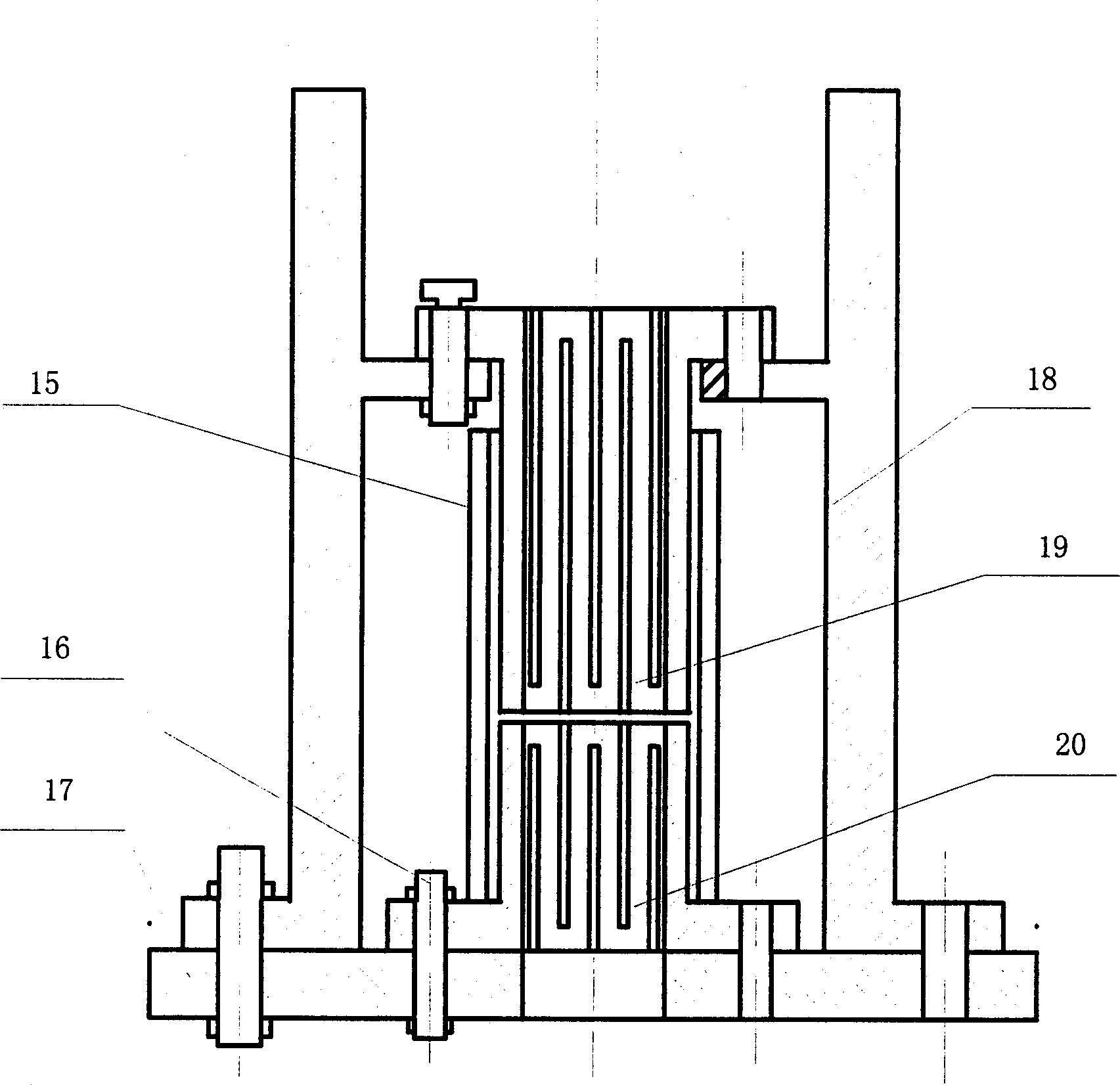

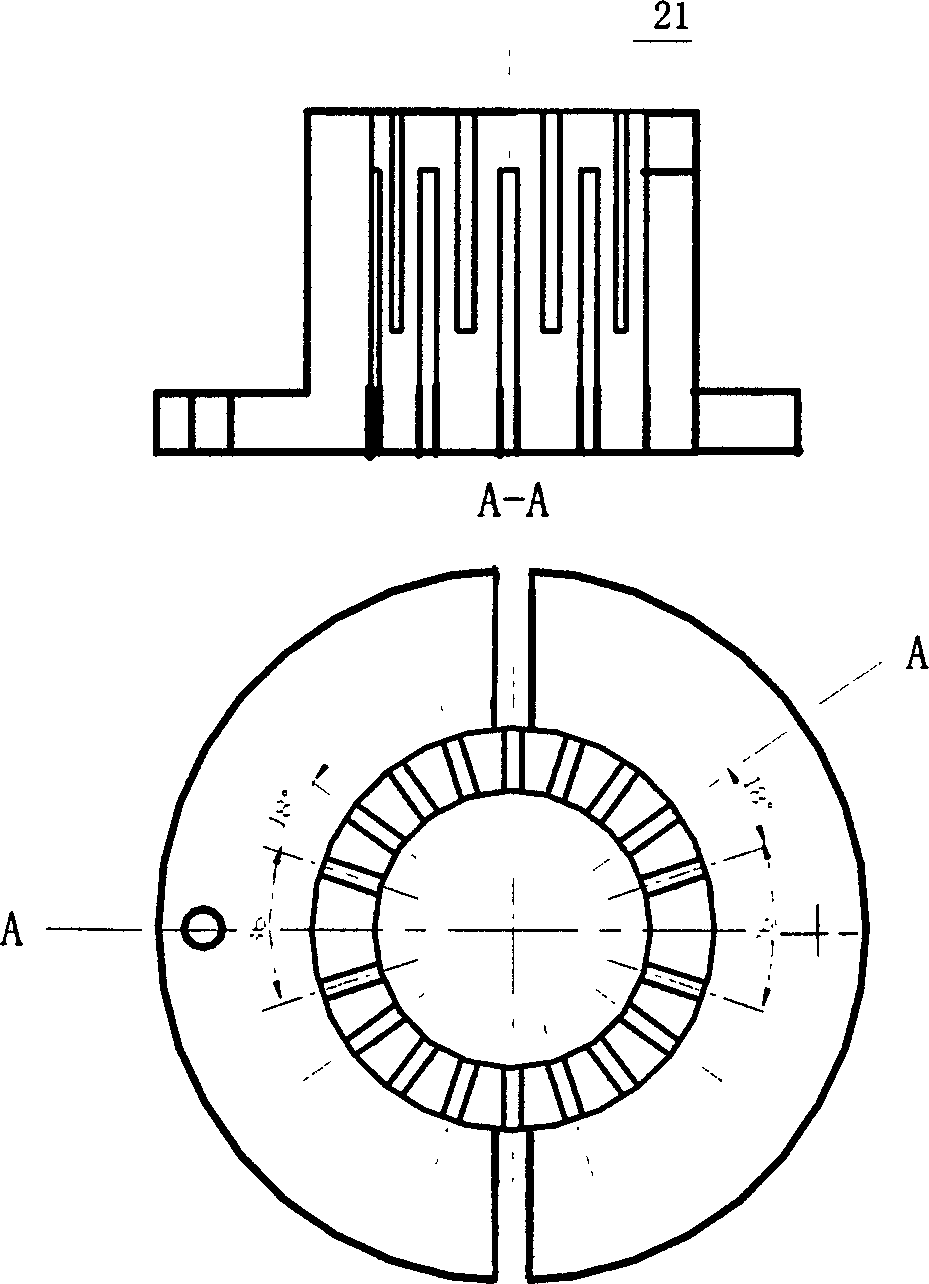

[0024] This embodiment includes a furnace body 1, a heating system, a cooling system, a vacuum system, a drawing system, and a control system. During implementation:

[0025] Furnace body 1: including the bottom plate 17 of the furnace body and the thermocouple 10 for measuring temperature.

[0026] Furnace body 1 is welded by stainless steel, is installed on the support 8, and its profile is cylindrical, adopts double-layer structure, so that pass through water to cool, and furnace door is a side door, links to each other with furnace body by bolt. There is an observation hole on the top cover of the furnace body, and quartz glass is installed in the hole, and a protective cover is provided. There are two temperature-measuring thermocouples 10 covered with ceramic tubes under the furnace body, and the ceramic tubes are inserted into the heating system 2 . A metal water-cooled electrode 16 is installed at the bottom of the furnace body, which is fastened together with the gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com