Walking type self balance mini-tiller

A self-balancing, micro tillage machine technology, applied in the field of soil tillage agricultural machinery, can solve the problems of reduced production efficiency, reduced output, increased operator work intensity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the drawings.

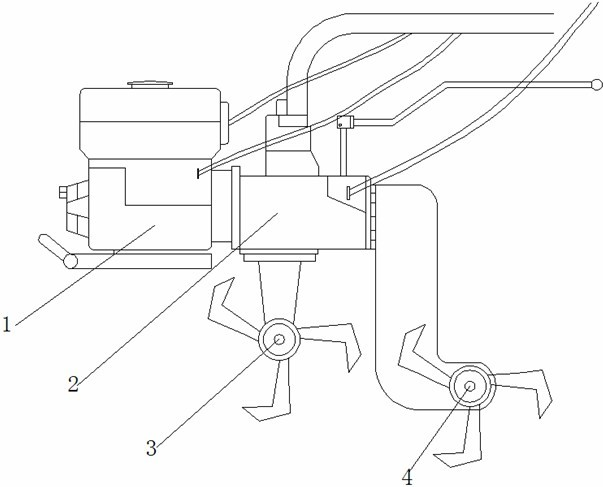

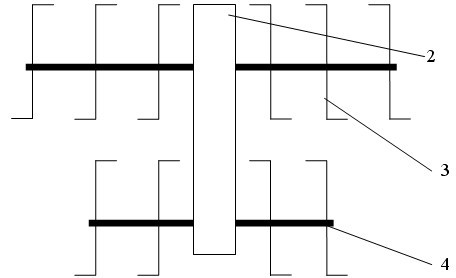

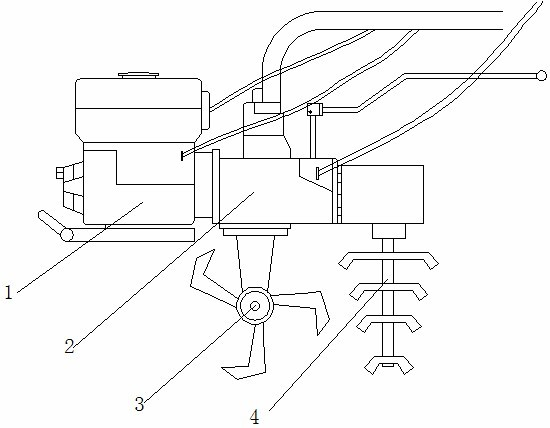

[0026] See figure 1 , figure 2 with image 3 As can be seen from the figure, the walk-behind self-balancing micro-tiller of the present invention includes an internal combustion engine 1, a gearbox 2 and a main rotary tiller 3. The output shaft of the internal combustion engine 1 is connected to the gearbox 2, and the output of the gearbox 2 passes The gear drive or chain drive drives the main rotary tiller 3 to rotate, and the knife axis of the main rotary tiller is horizontally arranged parallel to the ground. The micro-tiller also includes an auxiliary rotary tiller 4 that plays a balancing role. The auxiliary rotary tiller 4 is located behind the main rotary tiller 3. The auxiliary rotary tiller is connected to the power mechanism and driven by the power mechanism to rotate its rotation can also achieve alignment. Cutting of soil. The power driving the auxiliary rotary tiller 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com