Equipment in use for fork truck anti drifting-down freight

A technology of anti-dropping device and cargo, applied in the direction of lifting device, etc., can solve the problem that the cargo cannot be prevented from falling, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

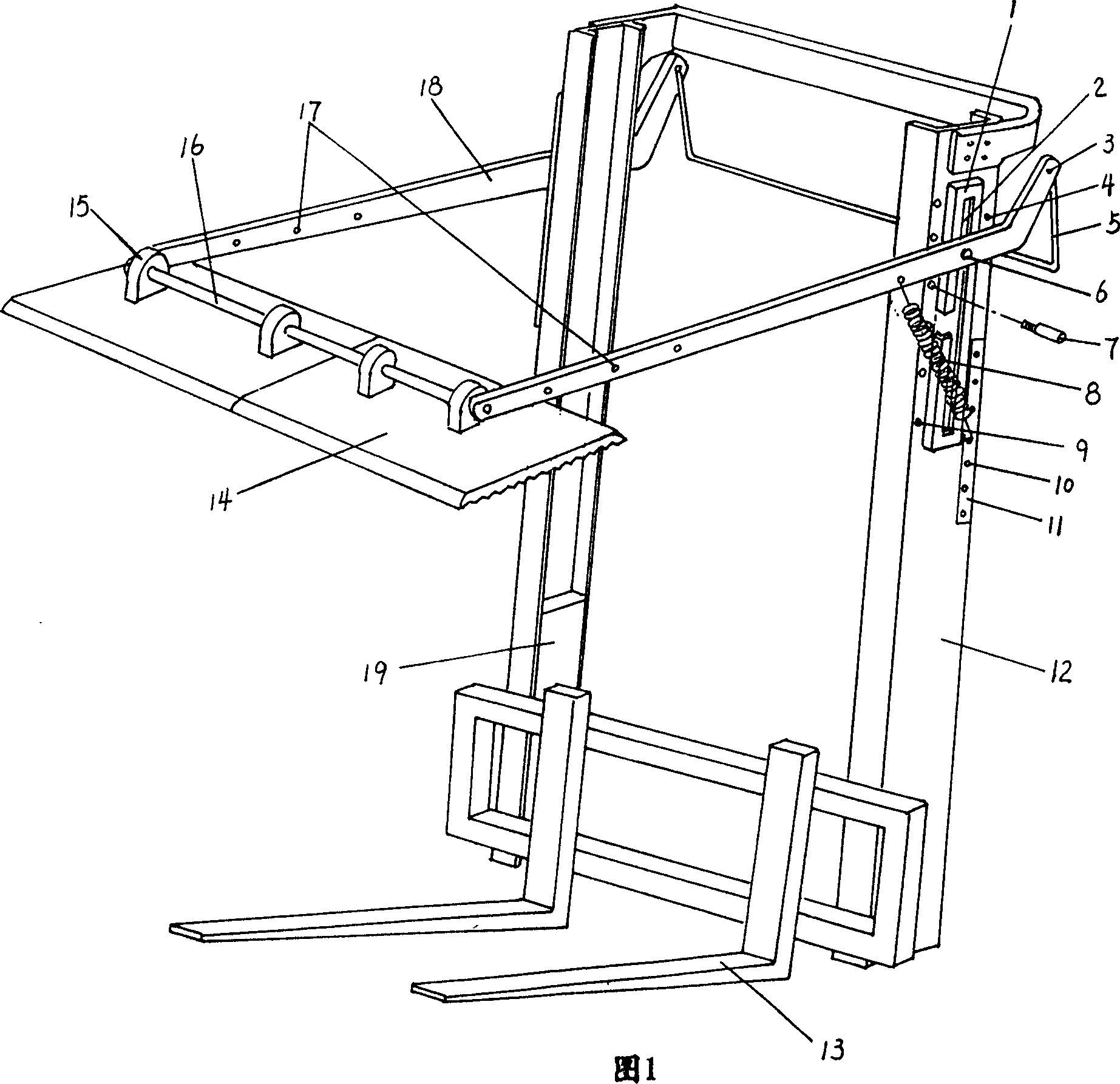

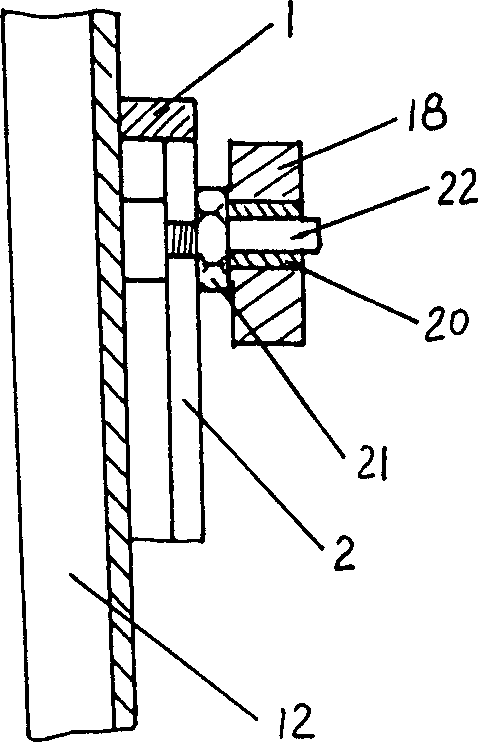

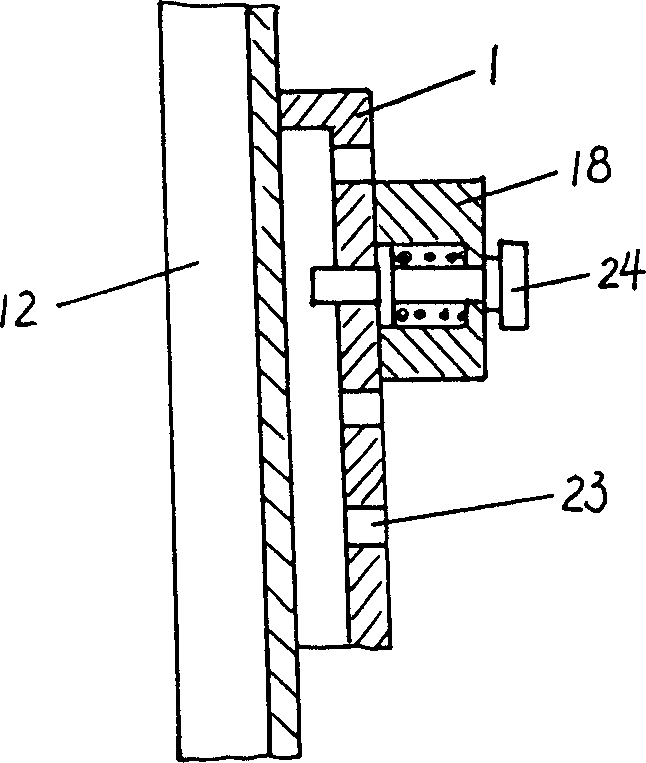

[0020] Please see Figure 1, figure 2 , a pair of elongated pressure arm connecting plates 1 are symmetrically fixed on the upper part of the two sides of the forklift mast 12 respectively, and the fixing method can be welding or riveting. A longitudinal adjustment groove 2 is opened in the longitudinal center of the pressing arm connecting plate 1 . A pair of pressing arms 18 are pressed at their position close to the tail and corresponding to the position of the longitudinal adjustment groove 2 to open the pressing arm shaft hole 6, and the bearing 20 is fixed in the pressing arm shaft hole 6. As the screw shaft 22 passes through the longitudinal adjustment Groove 2 and its front end are pierced into the bearing center hole of bearing 22, and the pivotal connection between a pair of pressing arms 18 and a pair of pressing arm connecting plates 1 can be realized. Since a locking nut 21 is screwed on the section between the pressing arm 18 and the pressing arm connecting plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com