Scratch-resistant hydrophobic glass and preparation method thereof

A hydrophobic glass and scratch-resistant technology, applied in the direction of coating, etc., can solve the problem that the hydrophobic film is easy to fade, and achieve the effect of reducing wear, preventing detachment, and improving adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

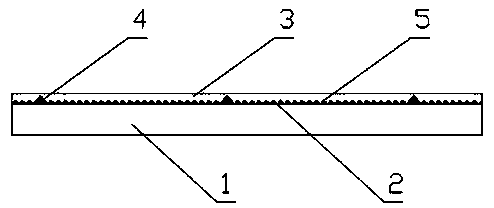

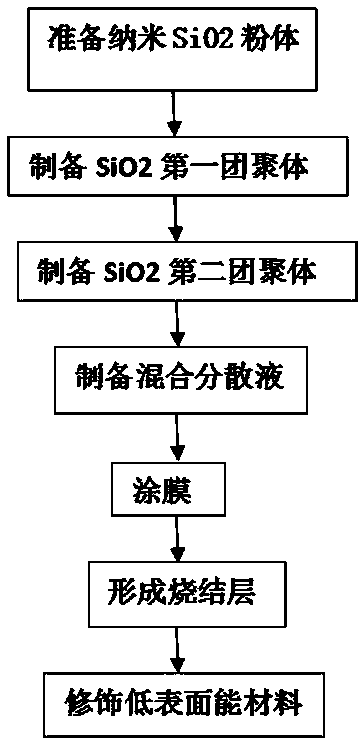

[0026] combine figure 1 and 2 , a scratch-resistant hydrophobic glass and a preparation method thereof, the specific implementation steps are as follows:

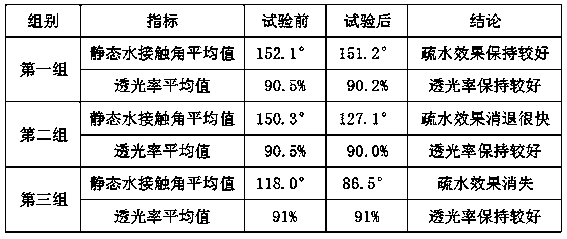

[0027] Prepare 9 pieces of identical glass, the size is: (length × width × thickness) 200mm × 200mm × 3mm, divided into three groups, each group of 3 pieces, the first group prepared hydrophobic glass according to the method of the present invention, the second and third groups Hydrophobic glasses were prepared according to prior art methods.

Embodiment 1

[0029] The first group of hydrophobic glass

[0030] A scratch-resistant hydrophobic glass, comprising an existing glass substrate 1 and a sintered layer 2 and a hydrophobic film 3 on the glass substrate 1, the sintered layer 2 is made of SiO with a particle size of 1000~1600nm 2 The first aggregate 4 and SiO with a particle size of 10-80nm 2 The second aggregate 5 is formed, the roughness of the sintered layer 2 is less than 80nm, SiO 2 First Agglomerates and SiO 2 The mass ratio of the second aggregate is 15%, SiO 2 The surface area of the glass substrate occupied by the first aggregate 4 is related to the SiO 2The ratio of the surface area of the glass substrate occupied by the second agglomerates 5 is 1%-5%.

[0031] A preparation method of scratch-resistant hydrophobic glass, the specific implementation steps are as follows:

[0032] a. Nano-SiO with a particle size of 10-25nm 2 Add 18g of the powder into 1.2L of absolute ethanol, first stir at high speed for 8m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com