Dry oil centralized lubrication system

A centralized lubricating and dry oiling technology, applied in lubricating parts, lubricating oil control valves, engine lubricating, etc., can solve problems such as oil shortage, blockage, burning loss of lubricating parts, and achieve the effect of preventing equipment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

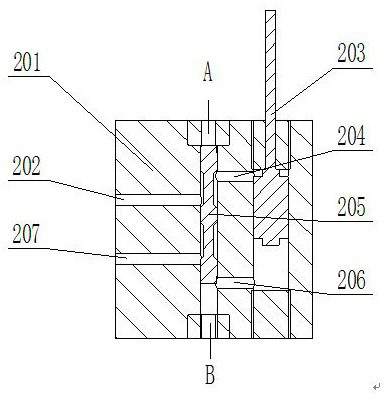

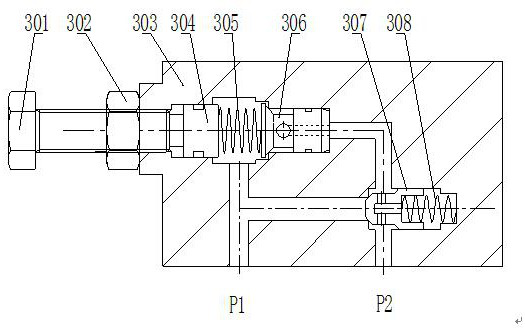

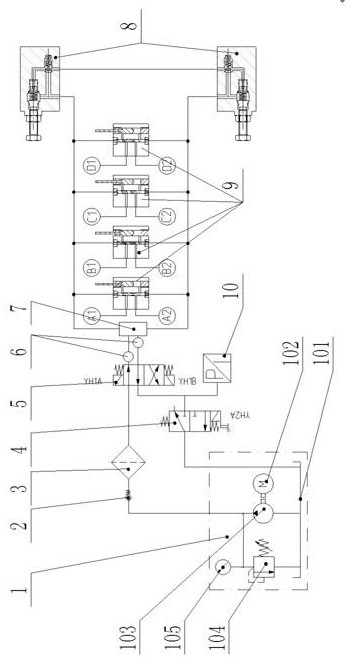

[0022]Example 1: seefigure 1 , A dry oil centralized lubrication system, the lubrication system includes a pump station assembly 1, a one-way valve 2, a filter 3, a two-position three-way electromagnetic reversing valve 4, a two-position four-way electromagnetic reversing valve 5, a flow meter 6. Rotary joint 7, one-way unloading valve 8, two-line distributor 9, pressure relay 10, and PLC control cabinet for controlling the pumping station, the pumping station assembly 1, one-way valve 2, filter 3, two-position three Two-way solenoid reversing valve 4, two-position four-way solenoid reversing valve 5, flow meter 6 are installed around the reel, rotary joint 7 is installed at the end of the reel; two one-way unloading valves 8 and multiple double lines The distributor 9 is installed inside a high-speed rotating drum. The pump station assembly 1 is connected to a one-way valve 2 and a two-position three-way electromagnetic reversing valve 4 at the same time. The one-way valve 2 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com