Air intake system for generating power by using cement kiln bypass flue gas waste heat

A technology for bypass ventilation and flue gas waste heat, which can be used in waste heat treatment, lighting and heating equipment, and process efficiency improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

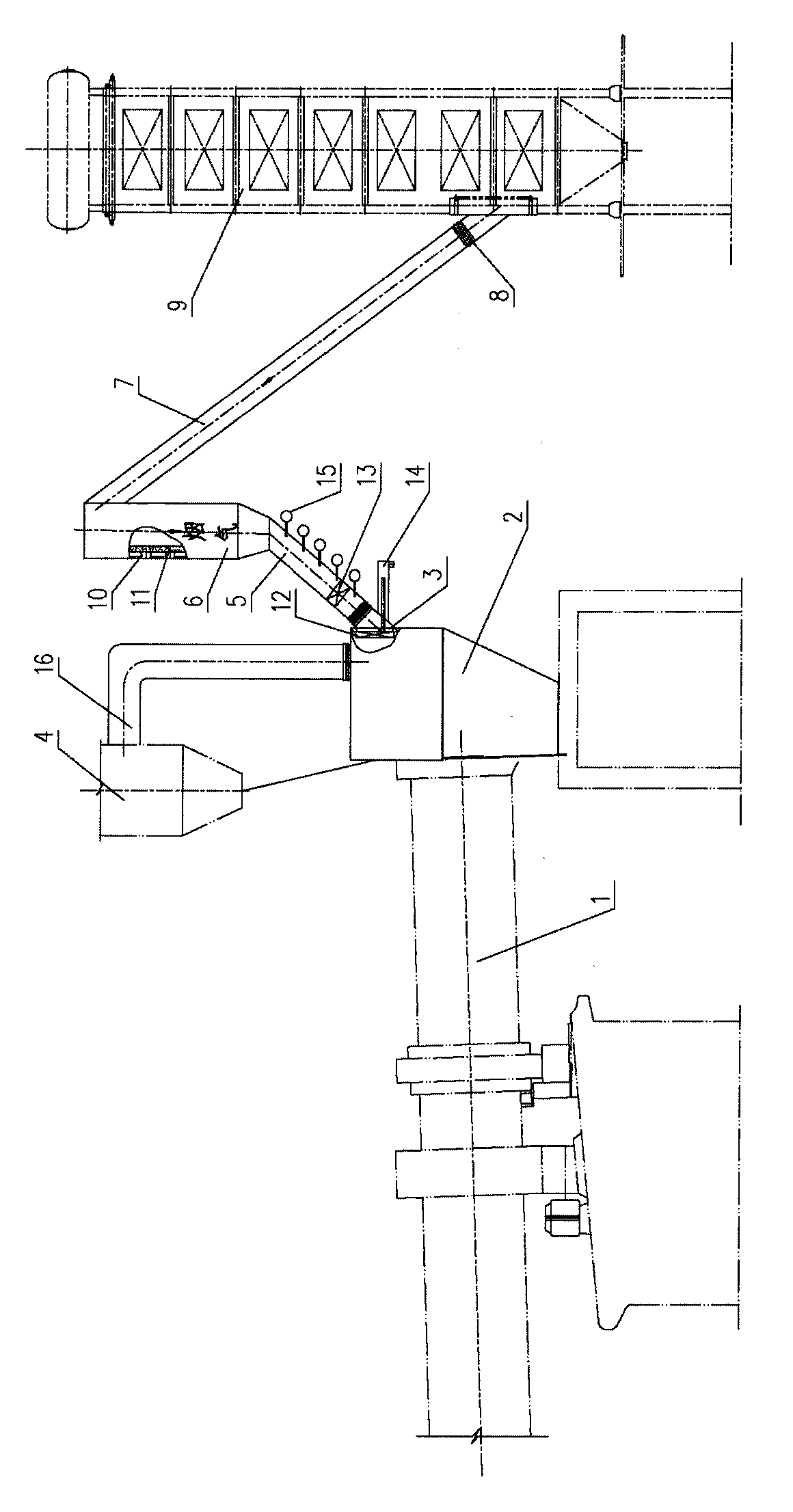

Embodiment 1

[0036] Such as figure 1As shown, an air intake is set on the side wall of the kiln tail smoke chamber, and a flexible ash blocking device is installed at the air intake. The flexible ash blocking device is a chain curtain or a spring curtain or a reed shutter. When taking the flexible ash-retaining device of the tuyere, part of the sticky dust sticks on the flexible ash-retaining device. The dust removal device arranged here can regularly remove the dust bonded to the flexible dust retaining device. A flue air valve is also set on the air taking pipe I to open the bypass flue gas. Multiple groups of air cannons are installed along the length direction of the wall surface of the air intake pipe I, which can remove the dust settled on the wall surface of the air intake pipe I, and make the dust fall into the rotary kiln. The top of the air pipe I is connected to the air pipe II, and the air pipe II is placed vertically. The flow velocity of the flue gas in the air pipe II is ...

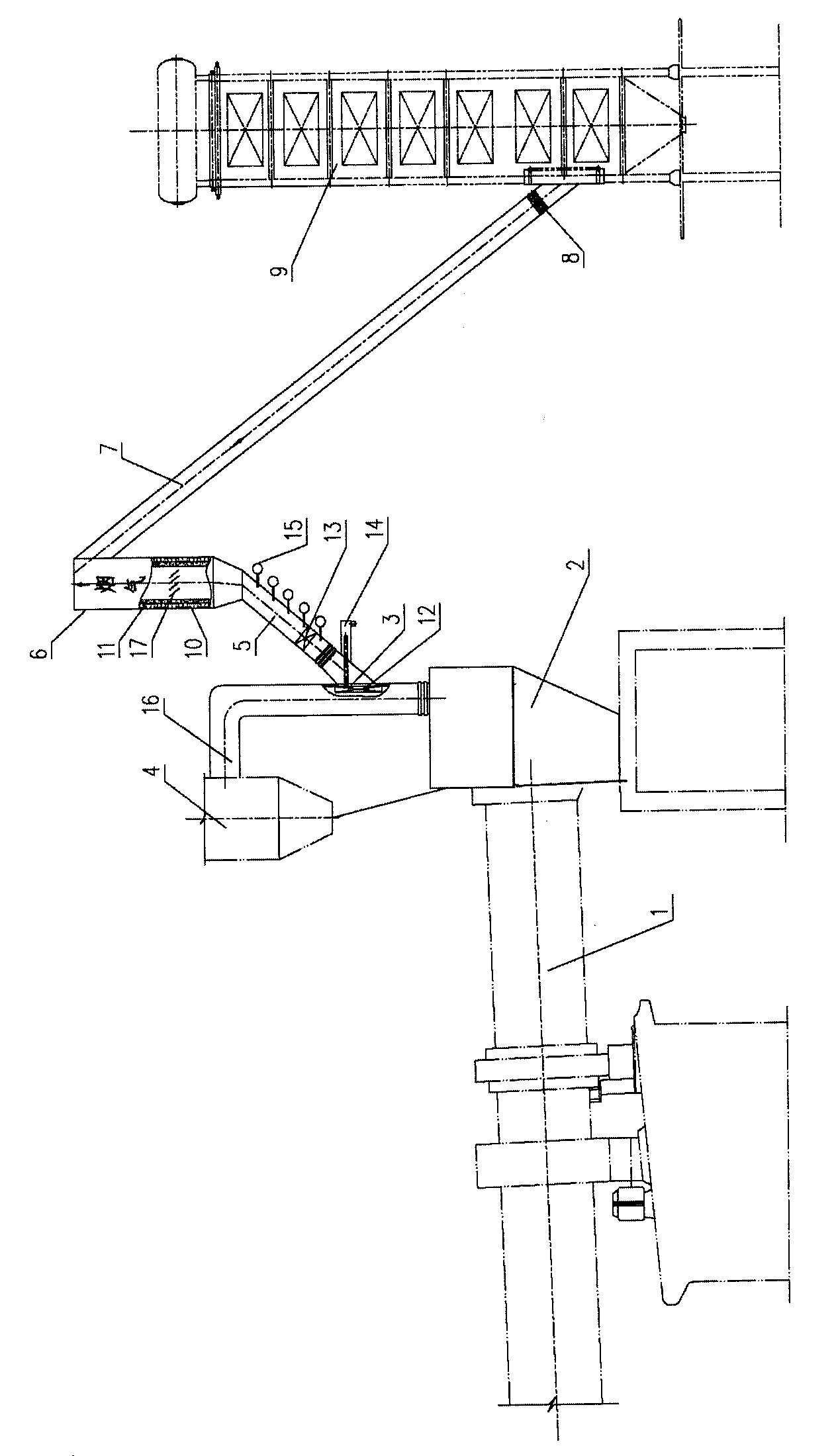

Embodiment 2

[0038] Such as figure 2 As shown, an air intake is set on the side wall of the ascending flue, and a flexible device is installed at the air intake. When the high-temperature exhaust gas from the bypass passes through the flexible device of the air intake, part of the sticky dust will stick to the flexible device. The dust removal device arranged here can regularly remove the dust adhered to the flexible device. The flue gas passes through the air intake pipe I connected to the air intake, and an expansion device is installed between the air intake pipe I and the air intake of the bypass air outlet, and a smoke damper is also installed on the air intake pipe I to perform bypass air release The opening of the smoke. A plurality of groups of air cannons are arranged in the length direction of the wall surface of the air intake pipe I to remove the settled dust on the wall surface of the air intake pipe I. The other end of the air pipe I is connected to the air pipe II, and th...

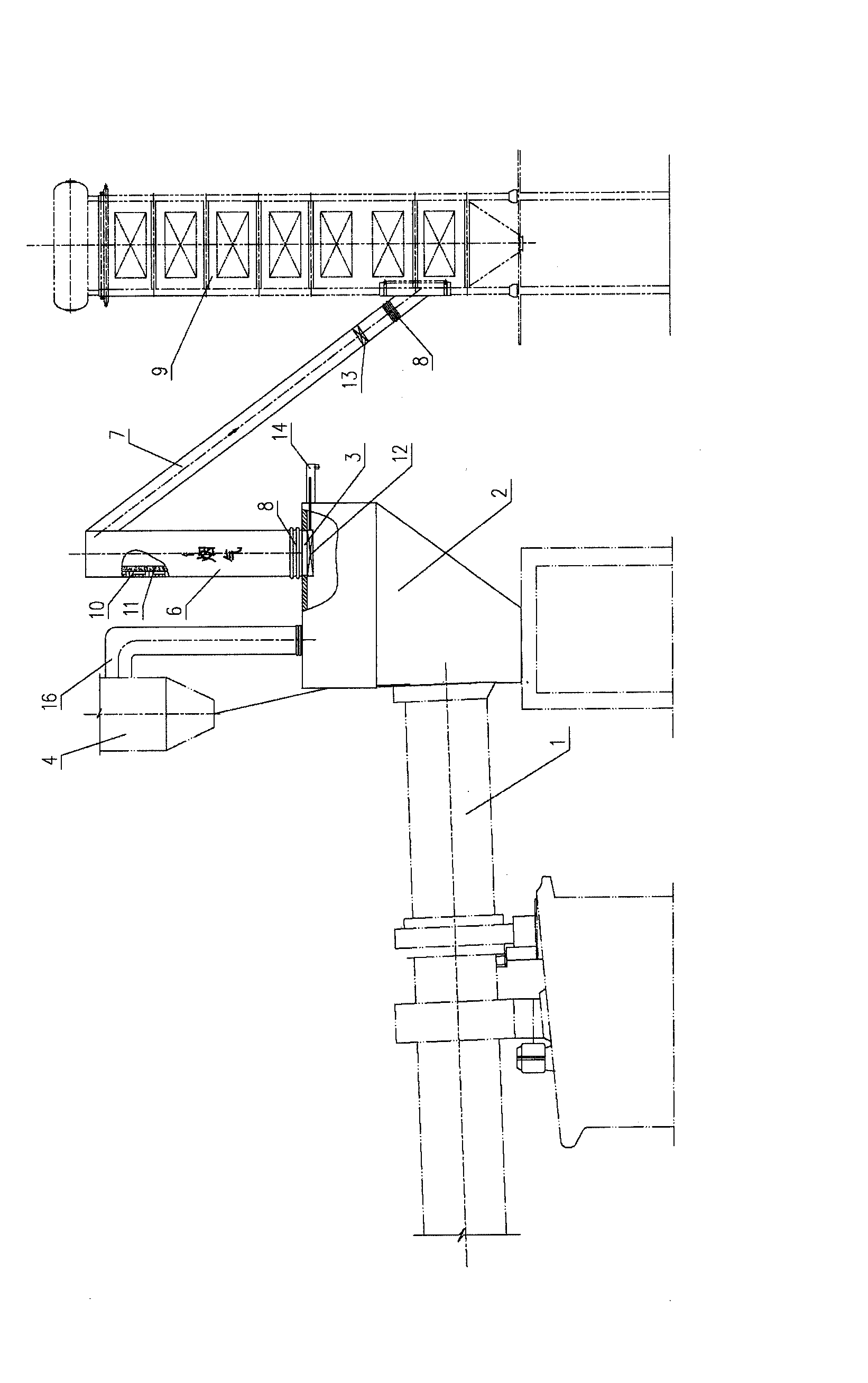

Embodiment 3

[0040] Such as image 3 As shown, an air intake is set on the top of the kiln tail smoke chamber, and a flexible device is installed at the air intake. When the bypass high-temperature flue gas passes through the flexible device at the air intake, part of the sticky dust sticks on the flexible device. The cleaning device at the location can regularly remove the dust stuck on the flexible device. The flue gas passes through the air intake pipe II vertically connected to the air intake port. The average flow velocity of the flue gas in the air intake pipe II is 7m / s, and the large-sized particles in the flue gas settle here and fall directly to the kiln tail smoke chamber Among them, the top of the air intake pipe II is closed, and an expansion device is set between the air intake pipe II and the air intake to prevent damage caused by the expansion of the pipeline. Open on the side wall near the top of the air intake pipe II and communicate with the air intake pipe III, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com