Green calcining equipment, system and process for producing gel materials from bulk solid waste

A gel material and calcination technology, applied in the field of environmental science, can solve problems such as system equipment and environmental impact, and achieve the effect of reducing the content of harmful components, eliminating the impact of production and operation stability, and solving the problem of SO2 emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

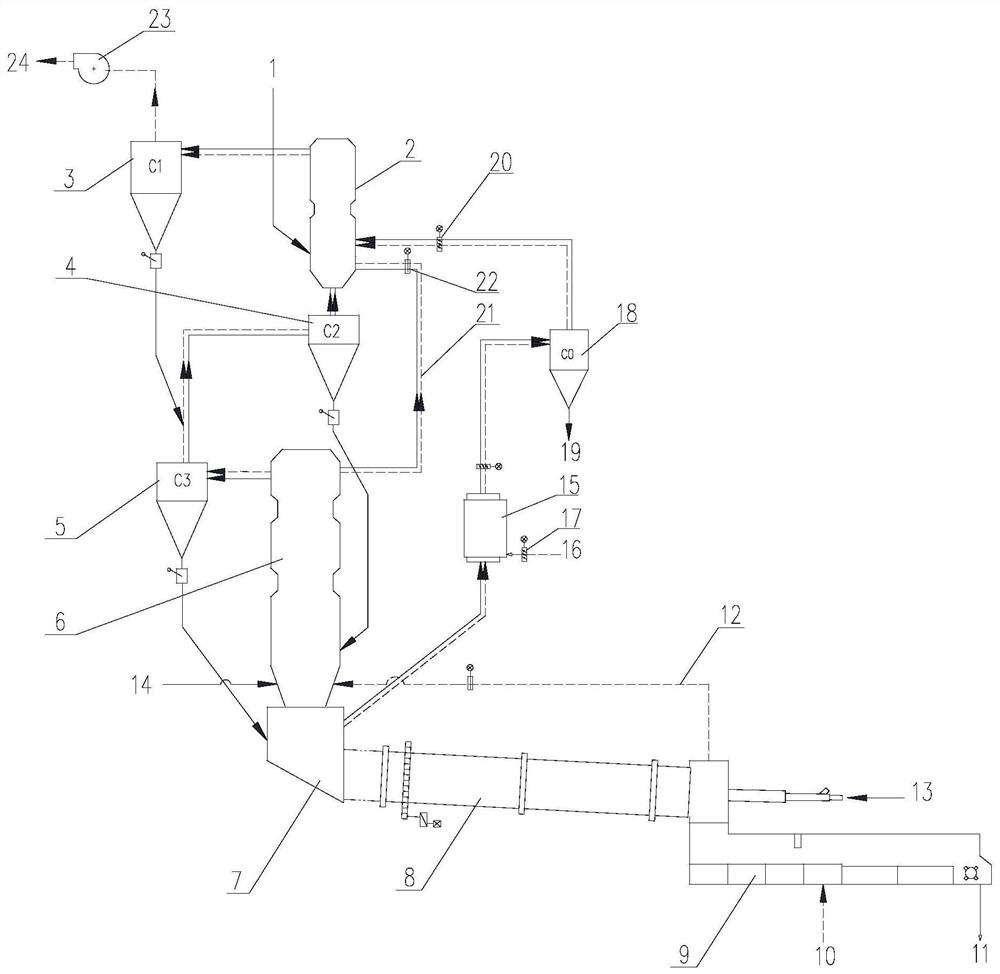

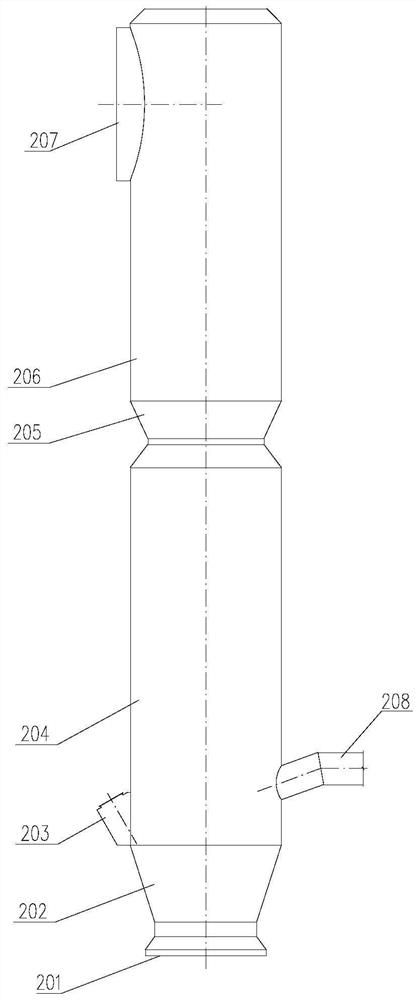

[0058] A kind of green calcining equipment that utilizes bulk solid waste to produce gel material, said green calcining equipment that utilizes bulk solid waste to produce gel material includes gel material generating equipment and desulfurization equipment, said gel material generating equipment includes decomposition furnace 6 , the desulfurization equipment includes a desulfurization reactor 2, and the decomposition furnace 6 communicates with the desulfurization reactor 2 through a desulfurization agent delivery pipeline 21.

[0059] The desulfurization delivery pipeline 21 is connected to the upper column of the decomposition furnace 6, and the desulfurization agent delivery pipeline 21 is provided with a valve C22. The CaO produced by pyrolysis of the raw meal 1 in the calciner has desulfurization activity, and is fed into the desulfurization reactor 2 through the desulfurizer delivery pipeline 21 to absorb the sulfur dioxide produced by the solid waste raw meal in the pr...

Embodiment 2

[0063] The invention also discloses a supporting calcining system for realizing the above-mentioned green calcining process. The system includes three parts: gel material generating equipment, desulfurization equipment and bypass ventilation equipment. Gel material generating equipment includes preheater, calciner 6, smoke chamber 7, sintering kiln 8, cooler 9 and tertiary air pipe 12; desulfurization equipment includes desulfurization agent delivery pipeline and desulfurization reactor; bypass ventilation equipment includes quenching and dust collectors. The present invention can solve the problem of SO in the calcined flue gas while preparing the active gel material. 2 Solve the problem of high content of sulfur, chlorine, alkali and other components in emissions and solid waste, and realize green production.

[0064] A green calcining system for producing gel material by utilizing bulk solid waste, the green calcining system for producing gel material by utilizing bulk sol...

Embodiment 3

[0081] A green calcination process for producing gel material by utilizing bulk solid waste, characterized in that: the green calcination process for producing gel material by utilizing bulk solid waste uses the process for producing gel material by utilizing bulk solid waste described in any one of the above Green calcination system, the green calcination process of producing gel material by utilizing bulk solid waste includes a gel material generation process, and the gel material generation process is as follows:

[0082] Step 1: After the bulk solid waste is separated from gas and solid by several stages of preheaters, it is fed into the decomposition furnace, and the temperature of the decomposition furnace is 800-1000°C;

[0083] The temperature of the calciner is controlled at 800-1000°C by controlling the amount of fuel fed into the furnace, and the carbonate in the material is decomposed to obtain CaO.

[0084] Step 2: Part of the material decomposed by the calciner e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com