Thermal-energy stepwise multi-use solution concentrating-regeneration device

A solution concentration and regeneration equipment technology, applied in lighting and heating equipment, refrigeration and liquefaction, multi-effect evaporation, etc., can solve the problems of unfavorable modular production, unfavorable space saving, large temperature difference loss, etc., and achieve the benefit of modular production , Reduce the number of production molds and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

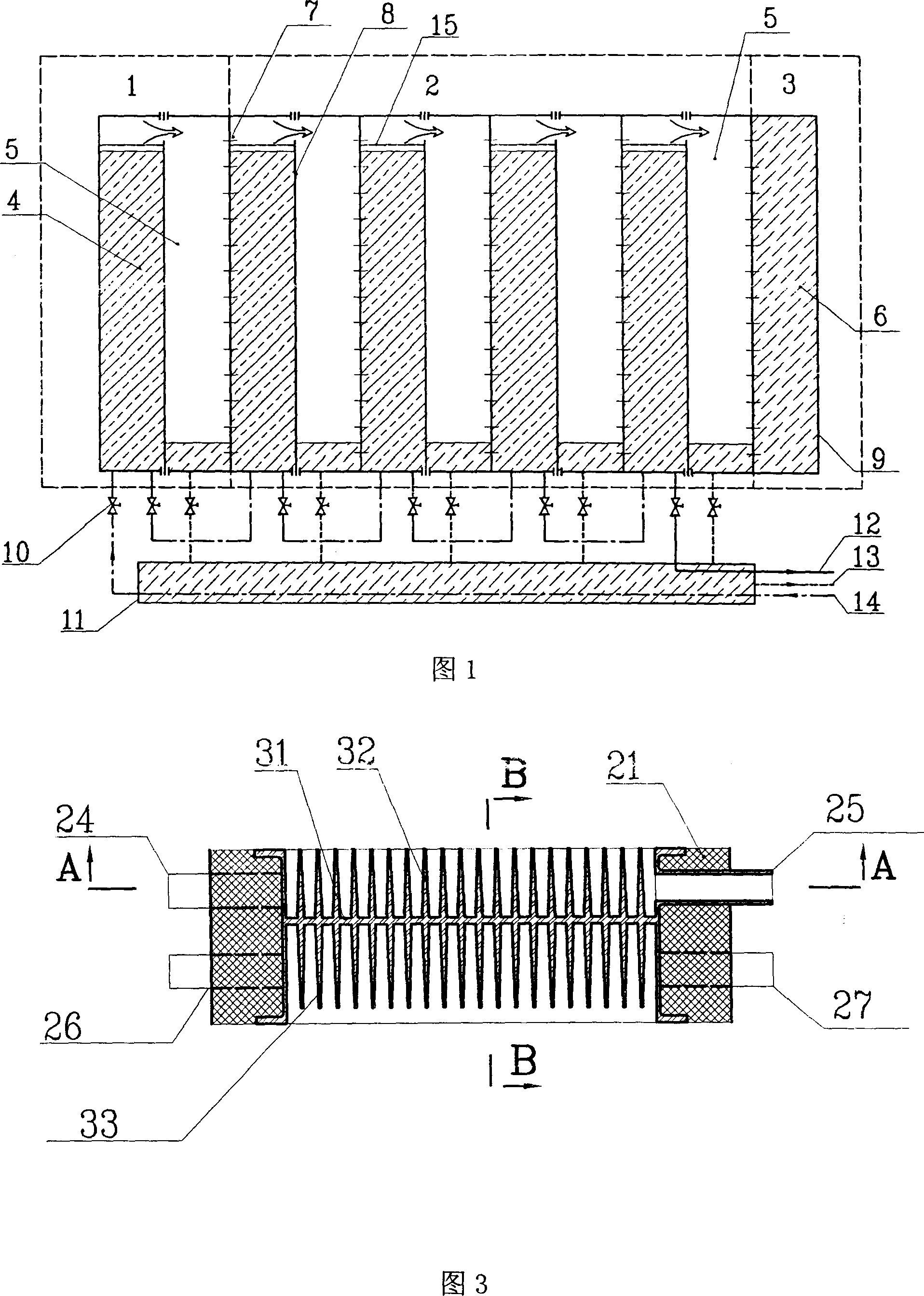

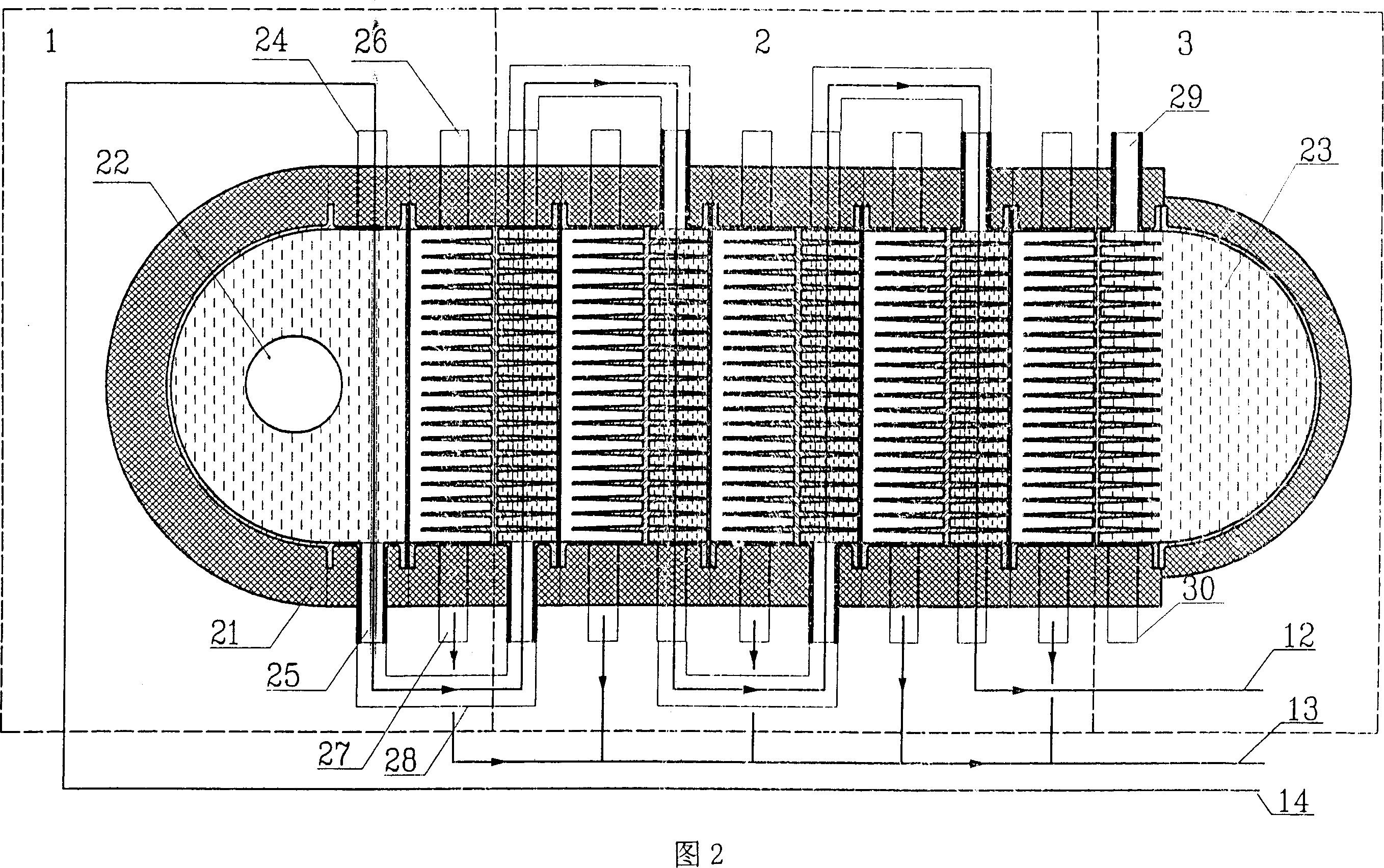

[0022] The purpose and effects of the present invention will be more obvious by referring to the accompanying drawings and specific examples in detail of the present invention.

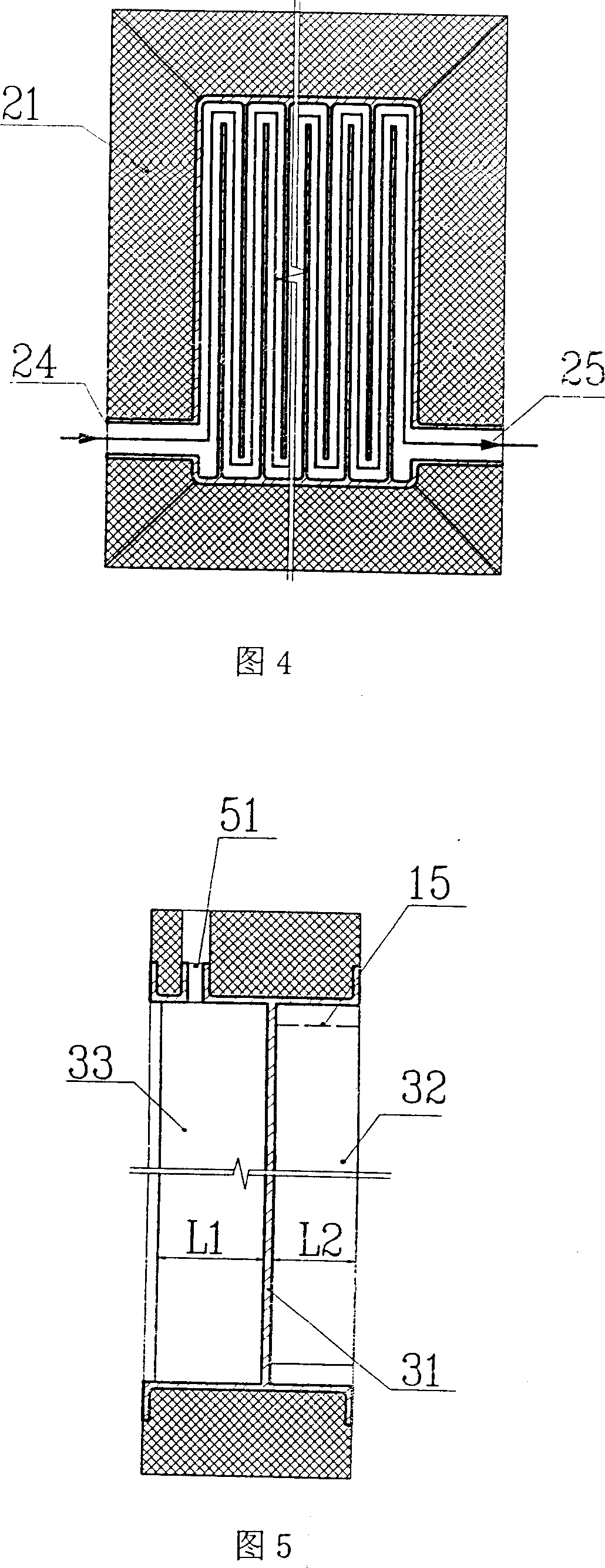

[0023] The device of the present invention is composed of a steamer, a heat exchange system, a peripheral piping system and an electronic control system, and can be divided into a series feeding connection method system shown in Figure 1 and a parallel feeding system shown in Figure 10 according to different feeding pipe connection methods. There are two kinds of material connection method systems. Because the peripheral equipment and pipeline system of the series feeding connection method system are relatively simple and more typical, the following analysis and description will be made based on this.

[0024] The device adopts the direct heat exchange method, and adopts the method of heat transfer ribs and surface treatment, which can well reduce the heat transfer resistance, thereby improving the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com