A bulldozer control method

A control method and bulldozer technology, which is applied to mechanically driven excavators/dredgers, etc., can solve the problem that bulldozers cannot meet the best operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

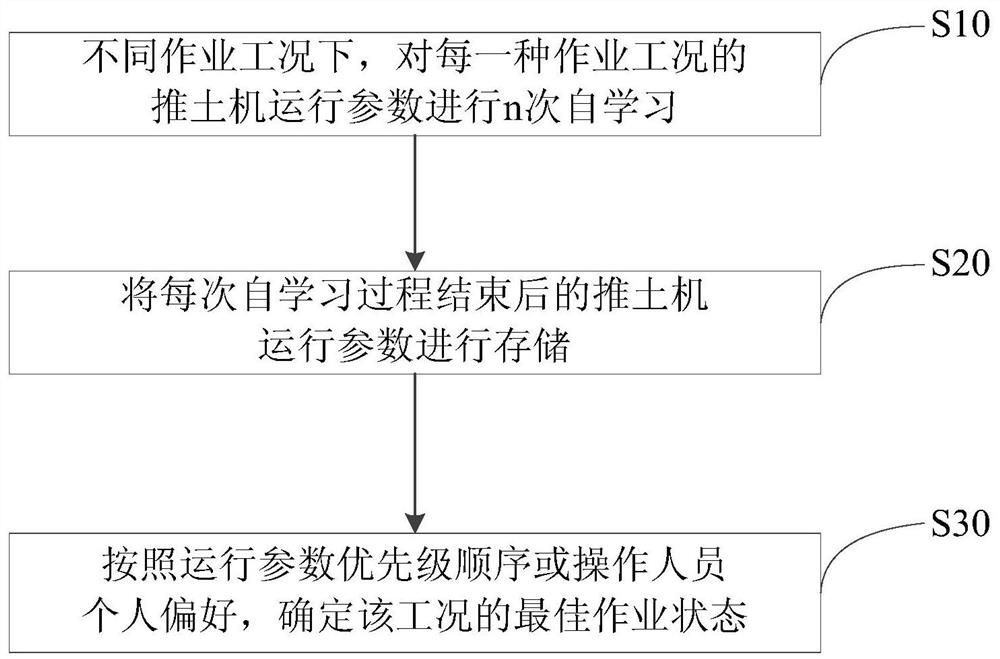

[0026] Such as figure 1 As shown, a kind of bulldozer control method provided by the present invention includes:

[0027] S10. Under different operating conditions, perform n times of self-learning on the operating parameters of the bulldozer for each operating condition:

[0028] The different working conditions of the bulldozer include different operators, different working objects and different working methods, etc. In this case, n times of trial operations are performed on the bulldozer operating parameters of each working condition to complete the self-learning stage. Specifically, enter the "best working mode" from the main display, select "start self-learning", the operator sets the engine speed n1, the vehicle speed gear F1 / R1, and after running the self-learning process once, click "single...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com