Shredded Tobacco Flavoring Tank and Flavoring Device

A shredded tobacco and incense pot technology, applied in the field of cigarette processing, can solve the problems of waste of spices, accelerated material falling, low usage rate, etc., and achieve the effects of prolonging the residence time, slowing down the falling speed, and increasing the falling resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

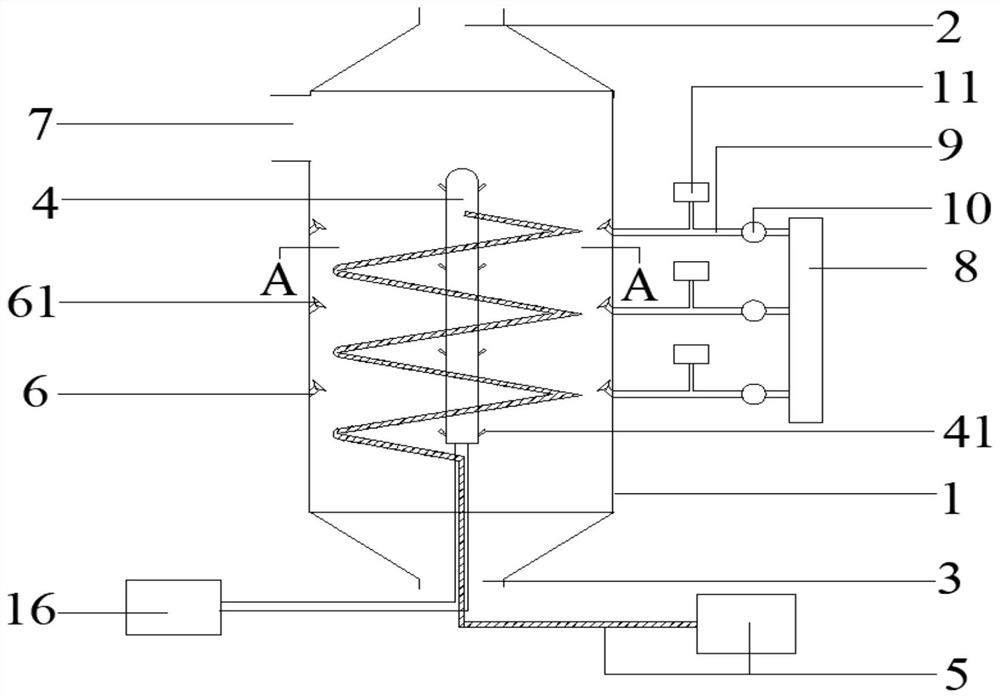

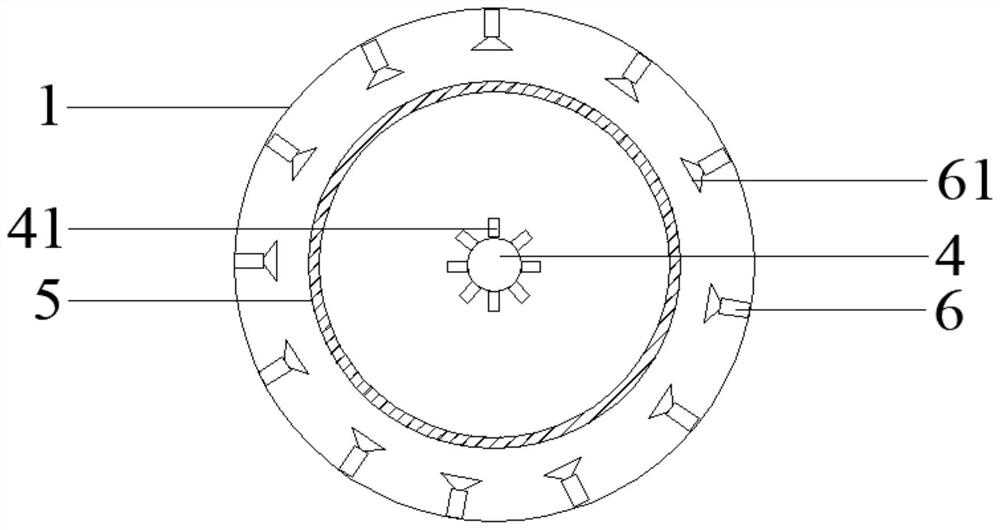

[0027] A shredded tobacco flavoring tank according to the present invention comprises a tank body 1, such as Figure 1-2 As shown, the tank body 1 is hollow, with an upper opening 2 and a lower opening 3 respectively, and a side opening 7 is provided on the side wall of the tank body 1 close to the upper opening 2 for the entry of shredded tobacco. A columnar air outlet pipe 4 is arranged in the middle of the tank body 1, and the surface of the columnar air outlet pipe 4 is evenly arranged in a ring shape with multiple circles of air outlets 41; between the columnar air outlet pipe 4 and the inner wall of the tank body 1, at least A vibrator 5; the inner wall of the tank body 1 is annularly provided with a multi-circle spice spray pipe 6, and the front end of the spice spray pipe 6 is connected to a large nozzle 61; the air outlet 41 and the spice spray pipe 6 are at a height Alternately arranged, that is, the height of the first circle of air outlets 41 is higher than or lowe...

Embodiment 2

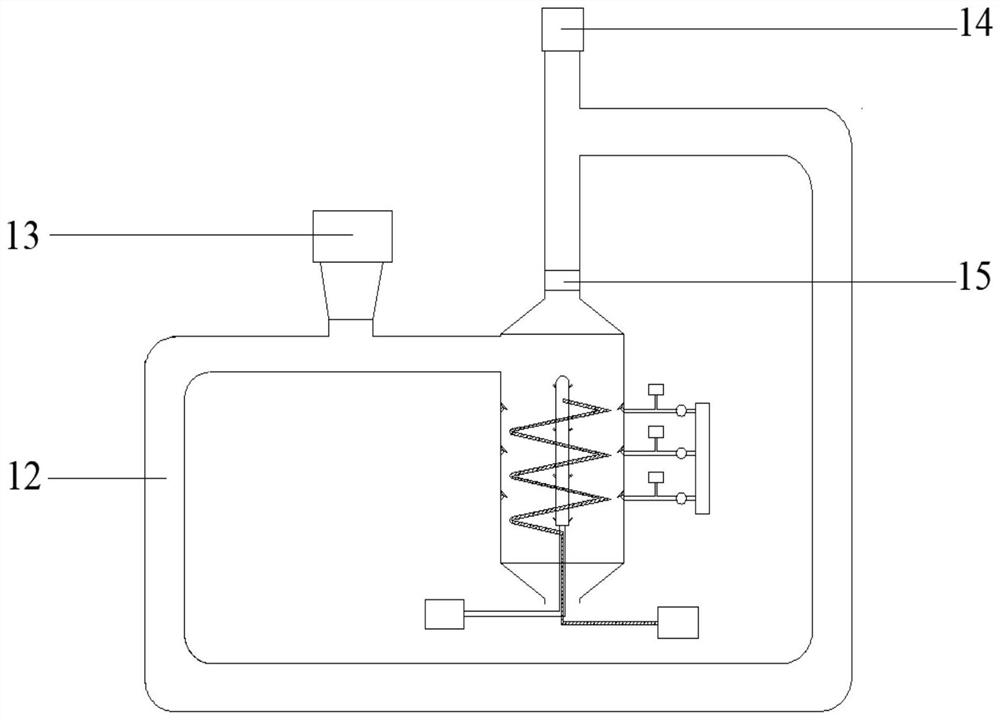

[0039] A shredded tobacco flavoring device, using the shredded tobacco flavoring tank described in any of the above embodiments, such as image 3As shown, the upper opening 2 is connected to one end of the ventilation duct 12 through the circulating fan 15, and the ventilation duct 12 is provided with a shredded tobacco blanking opening 13, on the ventilation duct 12 between the upper opening 2 and the shredded tobacco blanking opening 13 An exhaust port 14 is provided, and the other end of the ventilation pipe 12 is connected to the side opening 7 of the tank body 1; the rear end of the spice spray pipe 6 is connected to the spice barrel 8 through the infusion tube 9, and the infusion tube 9 is close to the spice barrel One end of 8 is provided with a flow meter 10 , and one end of the infusion tube 9 close to the large nozzle 61 is connected with an air compressor 11 .

[0040] In one embodiment of the present invention, the infusion tube 9 is provided with a switch (not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com