Liquid carbon dioxide cleaning system

A technology of liquid carbon dioxide and liquid carbon dioxide, which is applied in the field of liquid carbon dioxide cleaning system, can solve the problems that affect the cleaning effect and cannot guarantee stable liquid carbon dioxide output, so as to improve the cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The application will be described in detail below in conjunction with the accompanying drawings.

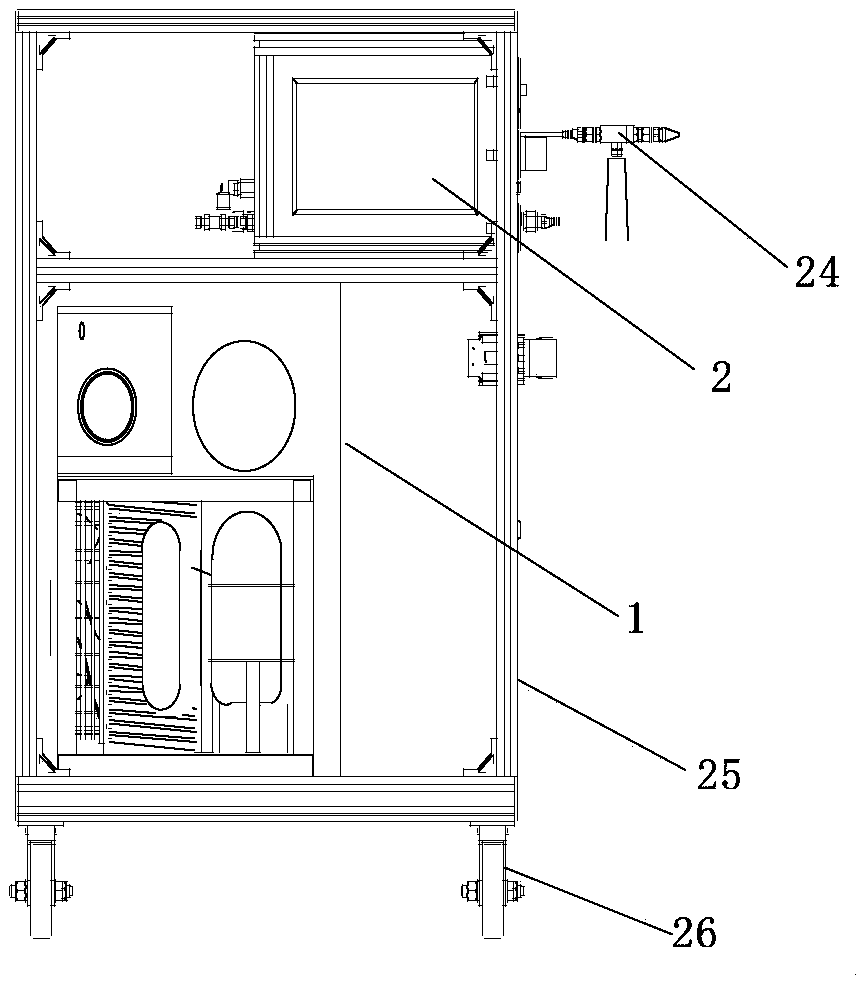

[0023] see figure 1 A schematic structural diagram of an embodiment of the liquid carbon dioxide cleaning system provided by the application, participate in figure 1 The device includes: a liquid carbon dioxide retention system 1 and an injection machine 2, the liquid carbon dioxide retention system 1 and the injection machine 2 are fixedly arranged in the casing shell 25, and universal wheels are also fixedly arranged at the bottom of the casing 26. The setting of the universal wheel 26 can ensure that the liquid carbon dioxide cleaning system can be moved conveniently to meet the needs of production.

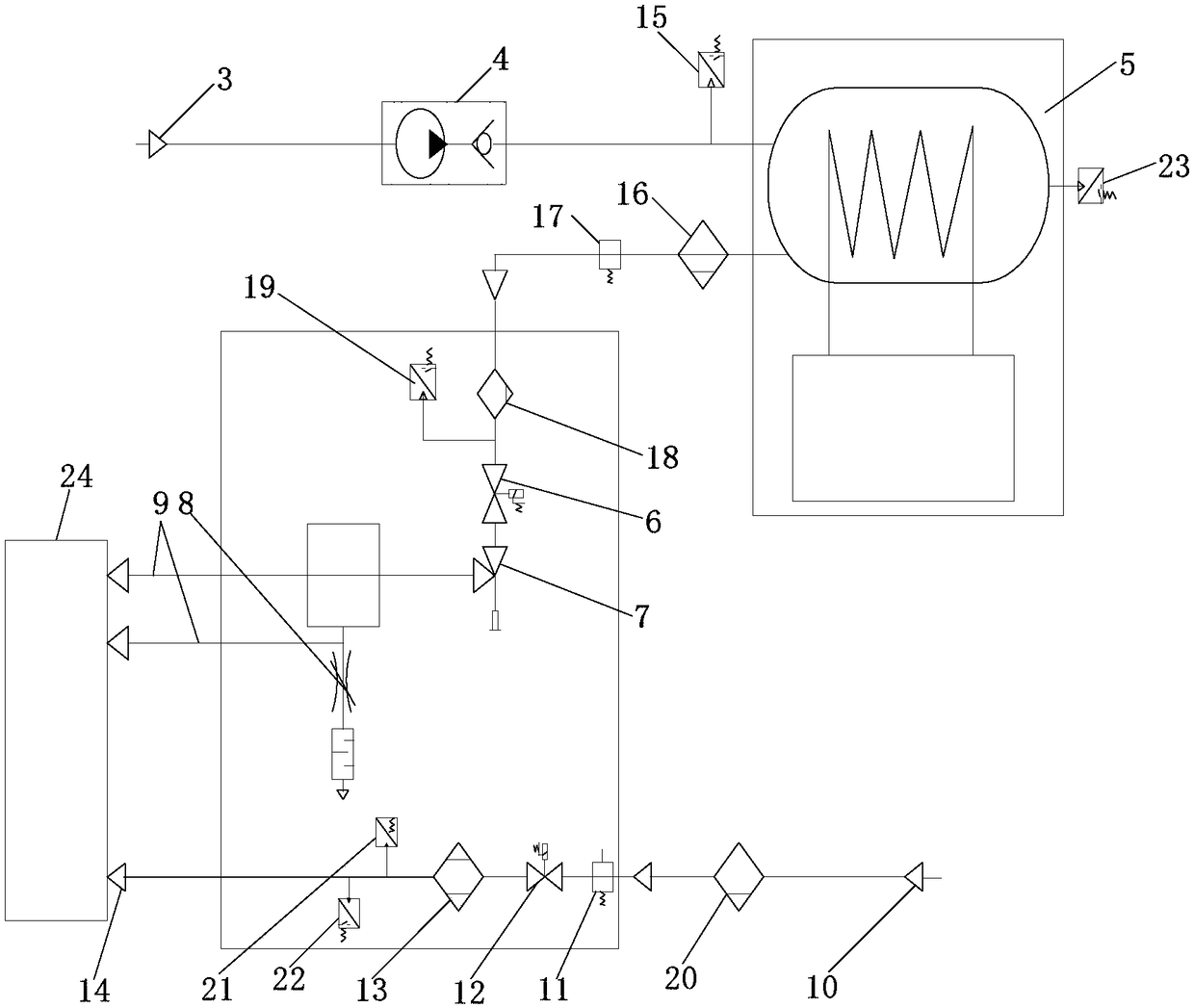

[0024] Such as figure 2 As shown, the liquid carbon dioxide holding system 1 includes a carbon dioxide inlet 3 , a supercharger 4 and a refrigerator 5 . The carbon dioxide inlet port 3 is connected to a carbon dioxide gas source, and the carbon dioxide generating devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com