Hammering device convenient to move and used for hardware machining

A hammer and hardware technology, which is applied in the field of hardware tool machinery applications, can solve the problems of complicated and troublesome device design, inconvenient operation of the principle, inconvenient installation and disassembly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

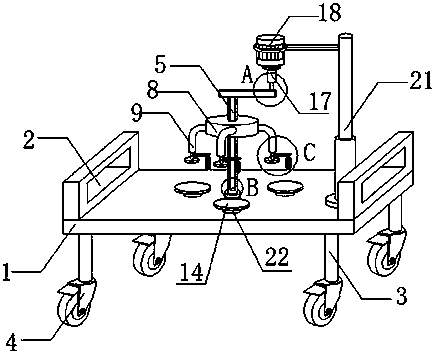

[0024] see Figure 1-5 As shown, a hammer device for metal processing that is easy to move, includes a worktable 1, a universal wheel 4, a chute 6, a connecting rod 9, a baffle 11, a cross column 15, a motor 18, a shaft arm 20 and On the turntable 22, push handles 2 are provided at the edges of both sides of the workbench 1, legs 3 are provided at the four corners of the bottom end of the workbench 1, and universal wheels 4 are provided below the legs 3. The universal wheel 4 is arranged below the universal wheel. Since the universal wheel 4 has good mobility, the device is also movable, which is convenient for the operator to move it, and is convenient for different hardware parts. Hammer operation, and the center of the workbench 1 is provided with a main shaft 5, a number of base plates 14 are arranged around the main shaft 5, and the bottom end of the base plate 14 is provided with a turntable 22, by setting the turntable 22 below the base plate 14, thus in When hammering...

Embodiment 2

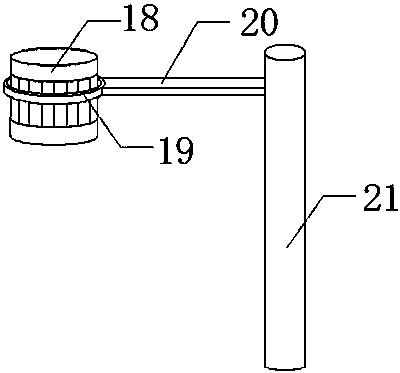

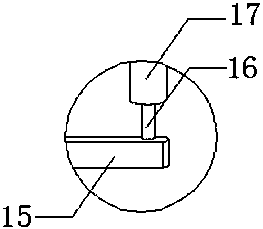

[0026] please continue Figure 1-5 As shown, the difference from the above-mentioned embodiment is: the bottom end of the shaft column 10 is provided with a baffle plate 11, and one side wall of the shaft column 10 is connected with a push plate 12, and one end of the push plate 12 is connected with a hammer block 13, By arranging several hammer blocks 13, the hammering operation can be performed on a corresponding number of hardware parts at the same time. The hammer block 13 and the bottom plate 14 are arranged symmetrically, and the position of the hammer on the hardware parts can be made more accurate by the symmetrical arrangement. The main shaft 5 is embedded with a chute 6, and the top of the main shaft 5 is connected with a horizontal column 15, and the other end of the horizontal column 15 is connected with a vertical column 16, and the top of the vertical column 16 is connected with a rotating shaft 17. By setting the rotating shaft 17, Therefore, the hammer block 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com