Multi-stage buffer for elevator

A buffer and secondary buffer technology, which is applied in the direction of elevators, transportation and packaging, etc., can solve the problems affecting the use of high-performance buffers, achieve the effects of short movement stroke, improved sealing, and reduced shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the purpose, technical solutions and beneficial effects of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

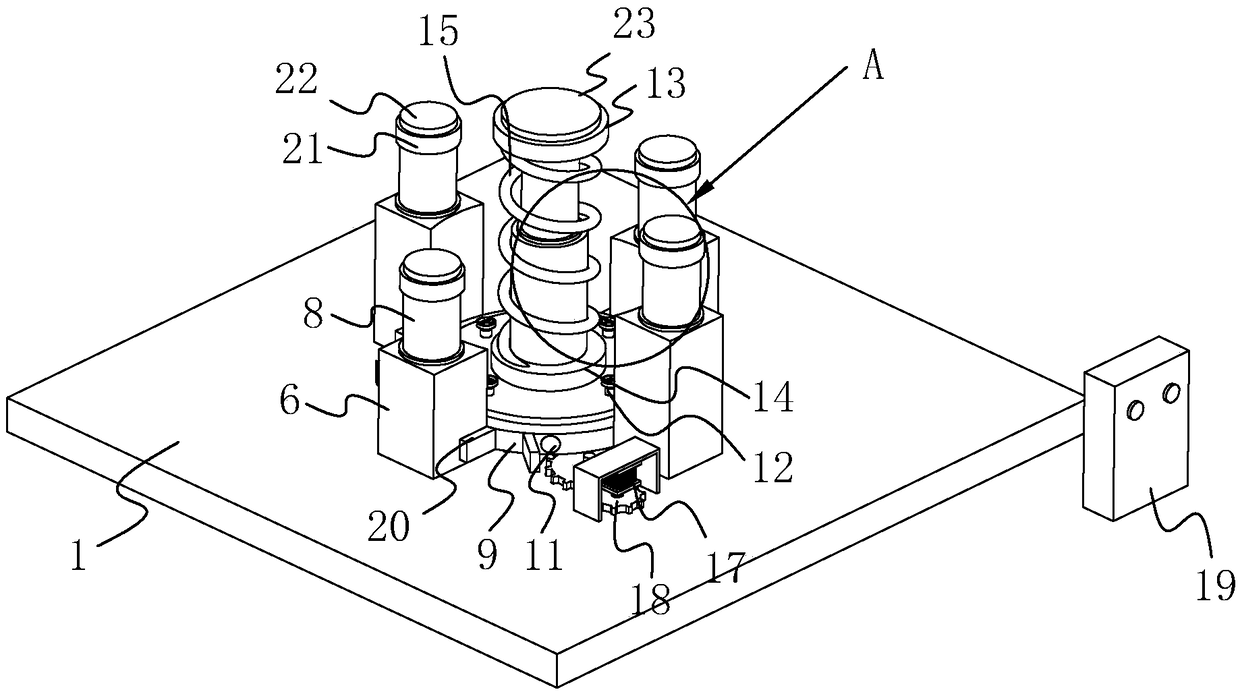

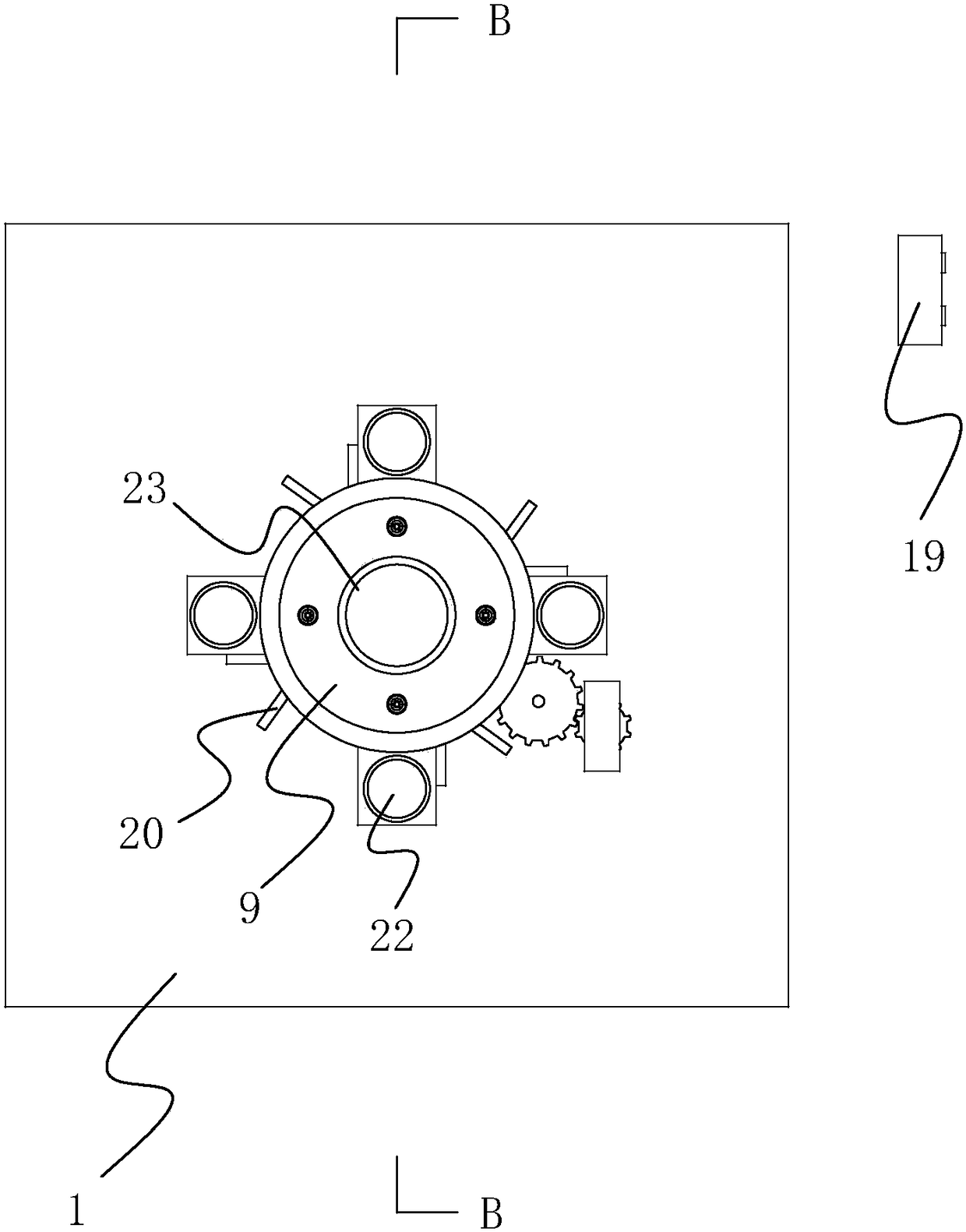

[0041] Such as figure 1 As shown, a multi-stage buffer for an elevator includes a base plate 1 placed in the pit of the hoistway, the base plate 1 is square, and the upper end surface of the base plate 1 is provided with a primary buffer assembly, a secondary buffer assembly and a conversion assembly.

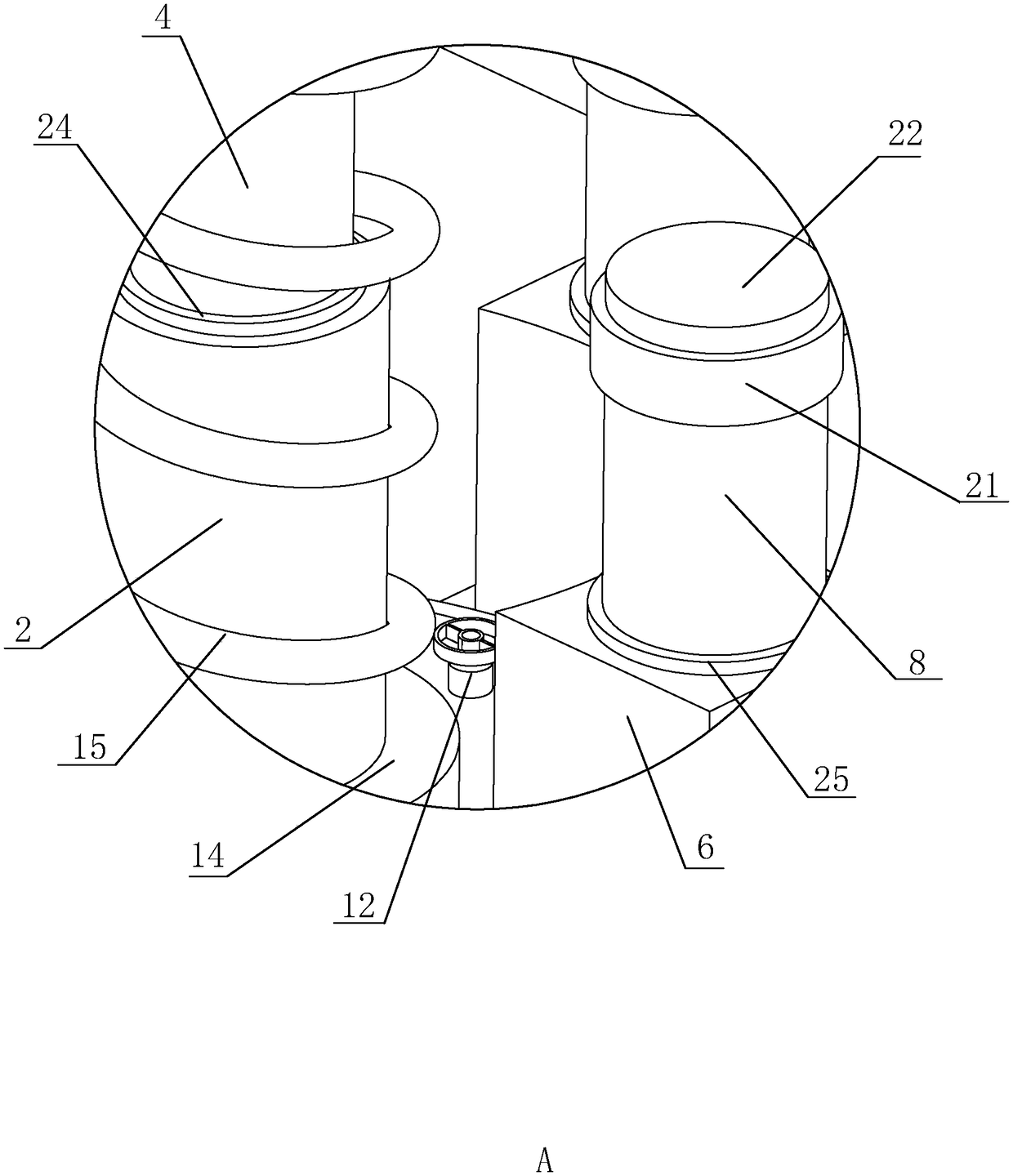

[0042] Primary buffer components such as figure 1 As shown, the primary buffer assembly includes a master cylinder seat 2 vertically fixed at the center of the upper end surface of the bottom plate 1, as Figure 4 and Figure 5 As shown, the top of the master cylinder block 2 has an open structure, and a main plunger 4 with a cavity 411 inside is slid along its axis. Por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com