Installation method for wall heating system

An installation method and wall technology, applied in the field of heating, can solve the problems of no uniform construction standards, uneven construction quality, unsatisfactory heating effect, etc., and achieve the effects of reducing heat loss, low construction difficulty, and increasing heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

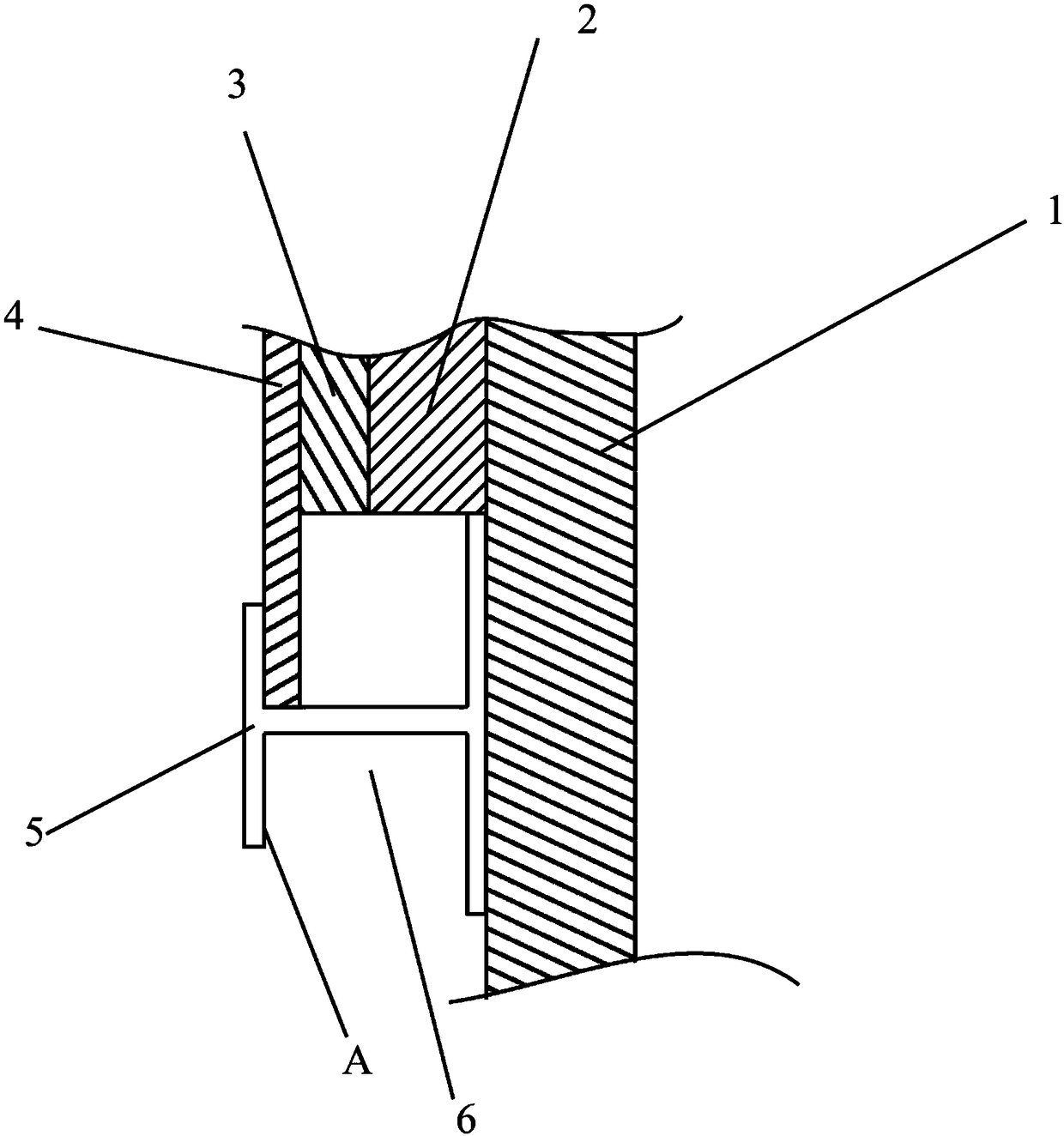

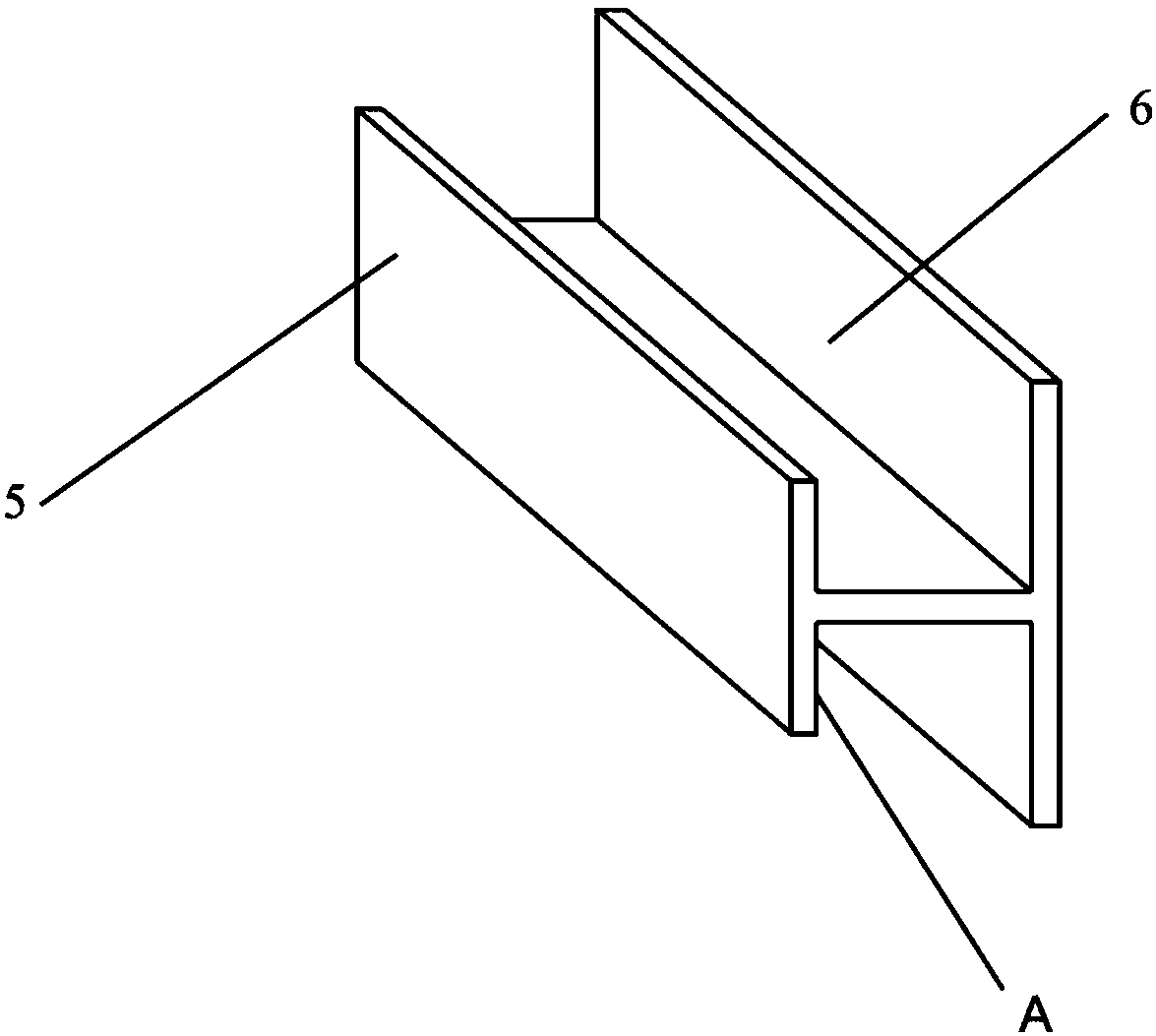

[0042] Embodiment 1 of the present invention discloses an installation method of a wall heating system, specifically for installing wall heating on a wall with a length of 5 m and a height of 1.84 m. The insulation board 2 used is 5 m in length and 0.6 m in width, and the horizontal clip 5 is 5 m in length. , The side width installed on one side of the wall body 1 is 17mm; specifically include the following steps:

[0043] (1) First, starting from the bottom of the wall 1 along the longitudinal direction of the wall 1, use gun nails to fix the three insulation boards 2 to the wall 1 at equal intervals, and the distance between the insulation boards 2 is 20mm;

[0044] (2) Then, cut the heating plate 3 according to the size of the thermal insulation board 2, and use the insulating tape to insulate the edge of the heating plate 3; at the position corresponding to the thermal insulation board 2, use the insulating tape to fix the heating plate 3 to the thermal insulation board 2 ...

Embodiment 2

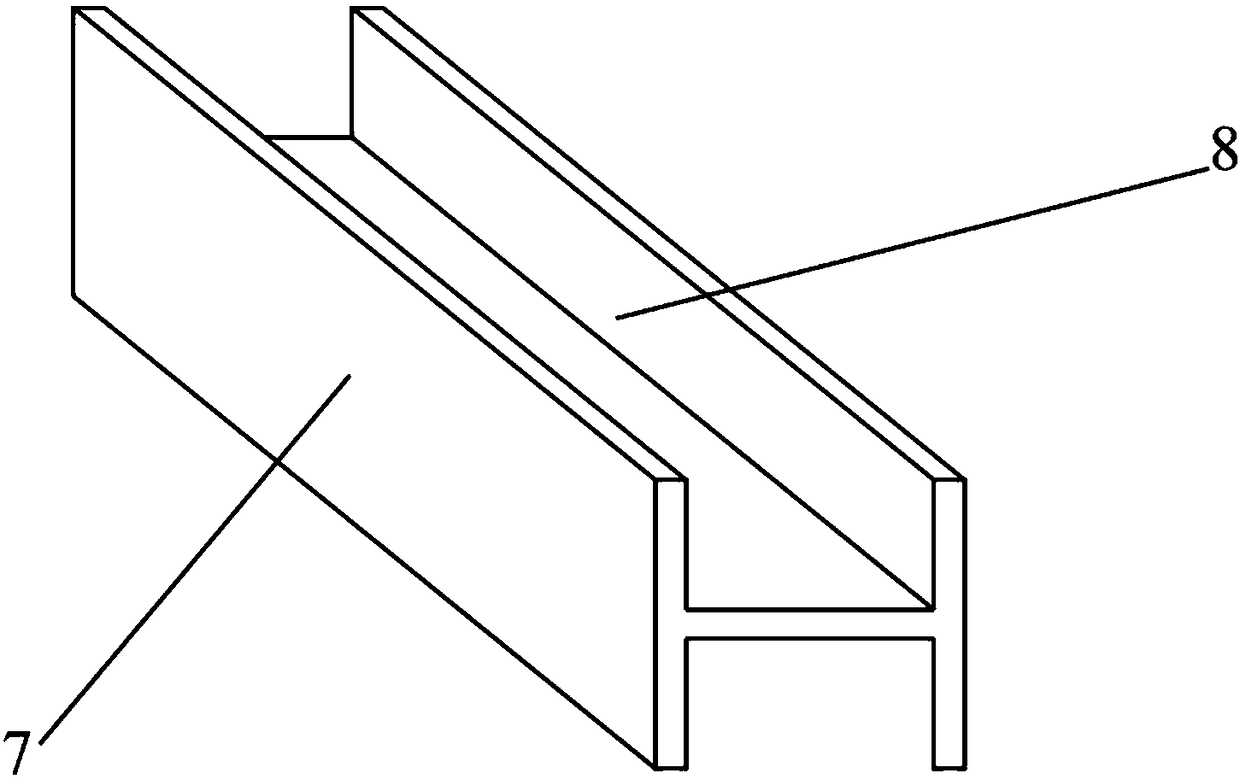

[0057] Embodiment 2 of the present invention discloses an installation method of a wall heating system. Specifically, a wall heater with a length of 5 m and a height of 2.8 m is installed on a wall with a length of 5 m and a height of 0.51 m. The insulation board 2 used is 5 m long and 0.5 m wide. m; the horizontal clip 5 used is 5m long, and the side width installed on one side of the wall 1 is 10mm; the specific steps are as follows:

[0058] (1) First, starting from the bottom of the wall 1 along the longitudinal direction of the wall 1, fix a thermal insulation board 2 to the wall 1 with gun nails;

[0059] (2) Then, cut the heating plate 3 according to the size of the thermal insulation board 2, and use the insulating tape to insulate the edge of the heating plate 3; at the position corresponding to the thermal insulation board 2, use the insulating tape to fix the heating plate 3 to the thermal insulation board 2 The side away from wall 1; solder the power line to the ed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com