Centrifugal compressor circumferential large interval small opening blowing combined with pulse excitation casing

A centrifugal compressor, excitation casing technology, applied in the direction of machine/engine, mechanical equipment, liquid fuel engine, etc., can solve the problems of surge, disadvantage, stable working range stall and surge, etc., achieve low efficiency and simple structure , the effect of convenient application implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

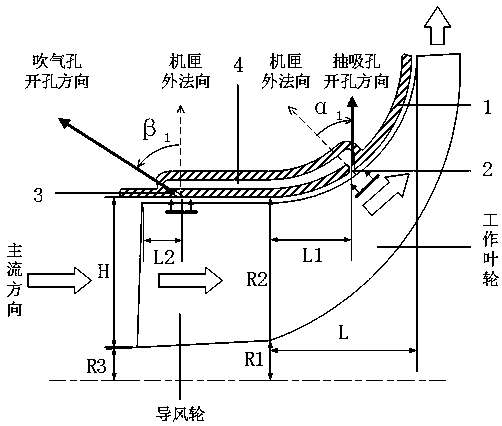

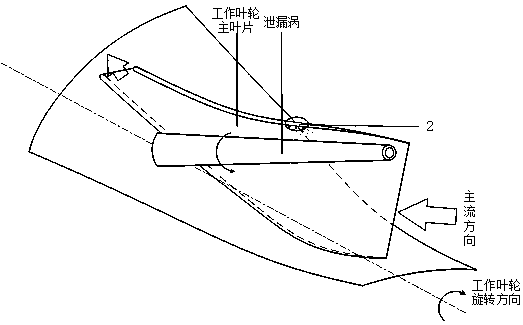

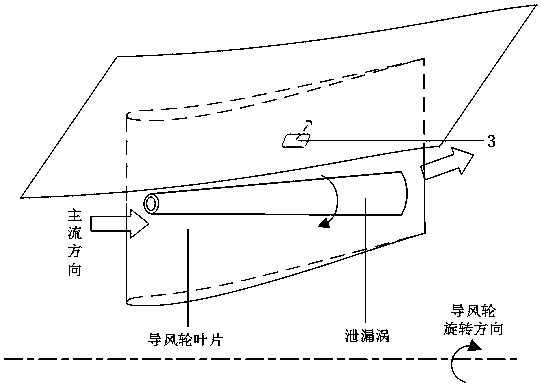

[0019] Centrifugal compressor casing with large intervals and small openings in the circumferential direction combined with blowing and pumping pulse excitation, including centrifugal compressor casing, suction hole structure, blowing hole structure and annular cavity; wherein, the suction hole structure is set in the centrifugal compressor The inner wall of the box is close to the front edge of the working impeller, and the air blowing hole structure is located at the inner wall of the centrifugal compressor casing near the front edge of the wind guide wheel. The suction hole structure and the air blowing hole structure pass through the casing along the cross-sectional area Constant or tapering annular cavity connection; the blowing hole structure has a larger interval along the circumferential direction, and the blowing hole structure has a larger interval along the circumferential direction; the centrifugal compressor has a large circumferential interval and a small opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com