Ramjet Radial Intake Distortion Suppression Grille and Its Design Method

A ramjet and grid technology, applied in the field of ramjet, can solve problems such as the shape of grid holes, the blockage of the pore size remaining unchanged, the difficulty in ensuring the effect of suppressing airflow distortion, the aerodynamic resistance of small engines, etc., to achieve convenient control. , Improve the anti-radial distortion ability, reduce the effect of internal aerodynamic resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings.

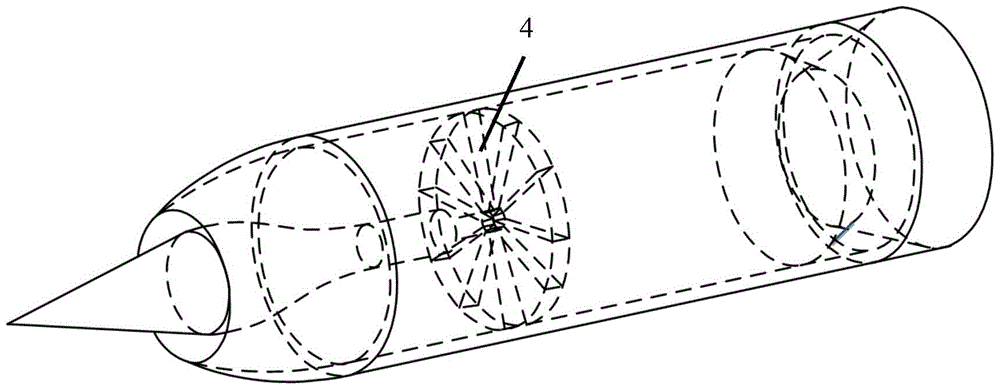

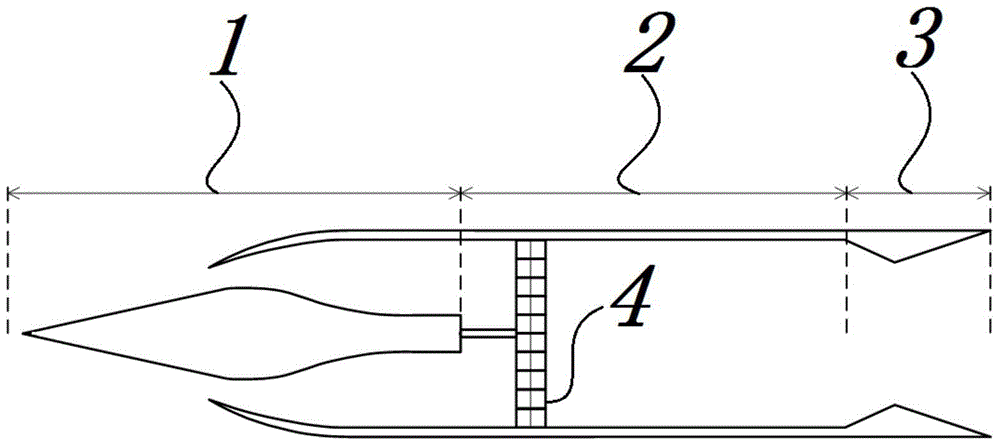

[0033] Such as Figure 1~6 As shown, the radial intake distortion suppression grid of the ramjet is installed in the internal flow channel of the ramjet, and the conventional ramjet is composed of a diffuser 1, a combustion chamber 2 and an exhaust nozzle 3, wherein the inlet cross section of the combustion chamber 2 is round. The ramjet radial intake distortion suppression grille 4 is installed at the entrance of the combustion chamber 2 .

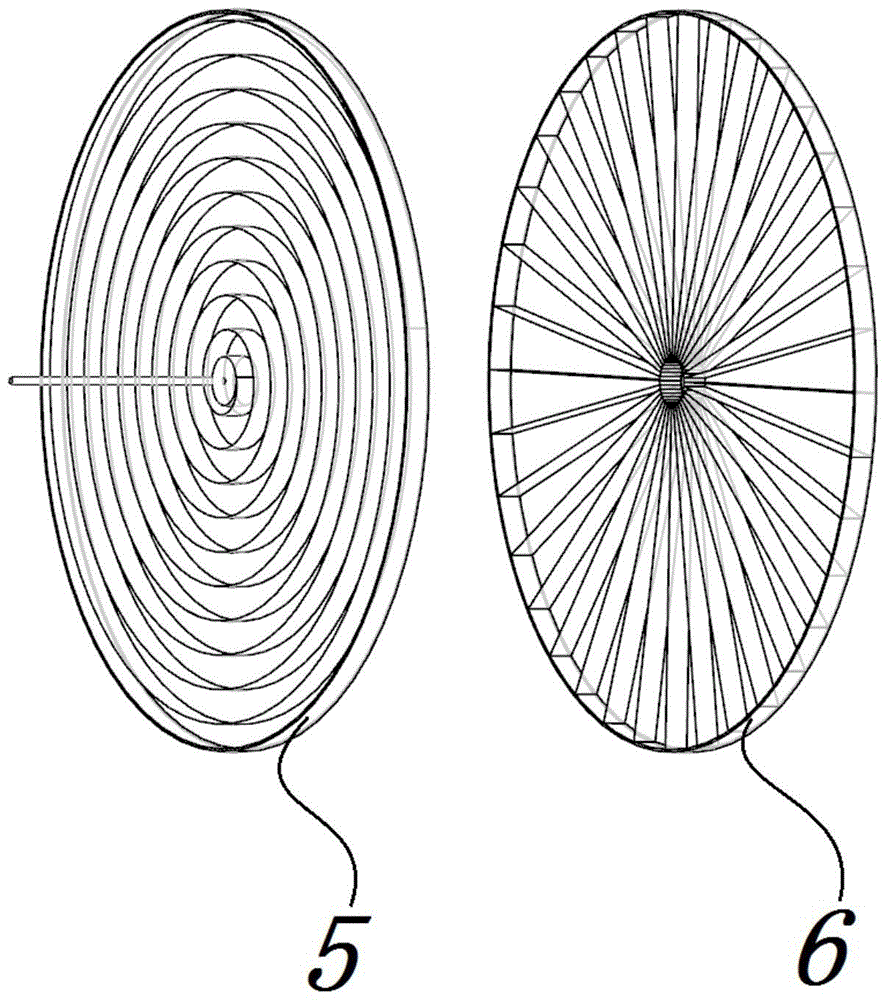

[0034] The radial intake distortion suppression grid of the ramjet is provided with a first distortion suppression grid piece 5 and a second distortion suppression grid piece 6, and the first distortion suppression grid piece 5 and the second distortion suppression grid piece 6 share Shafts are stacked together, the first distortion suppression grid sheet 5 is composed of a flexible spiral sheet around the central drum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com