A pulse solenoid valve

A technology of pulse solenoid valve and valve body, which is applied in the direction of valve details, valve device, valve shell structure, etc., can solve the problems of reducing the reaction speed, effectively cleaning the internal cavity, affecting the sealing performance of pulse solenoid valve, etc., so as to prevent sealing failure problem, save cleaning time, and facilitate independent cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

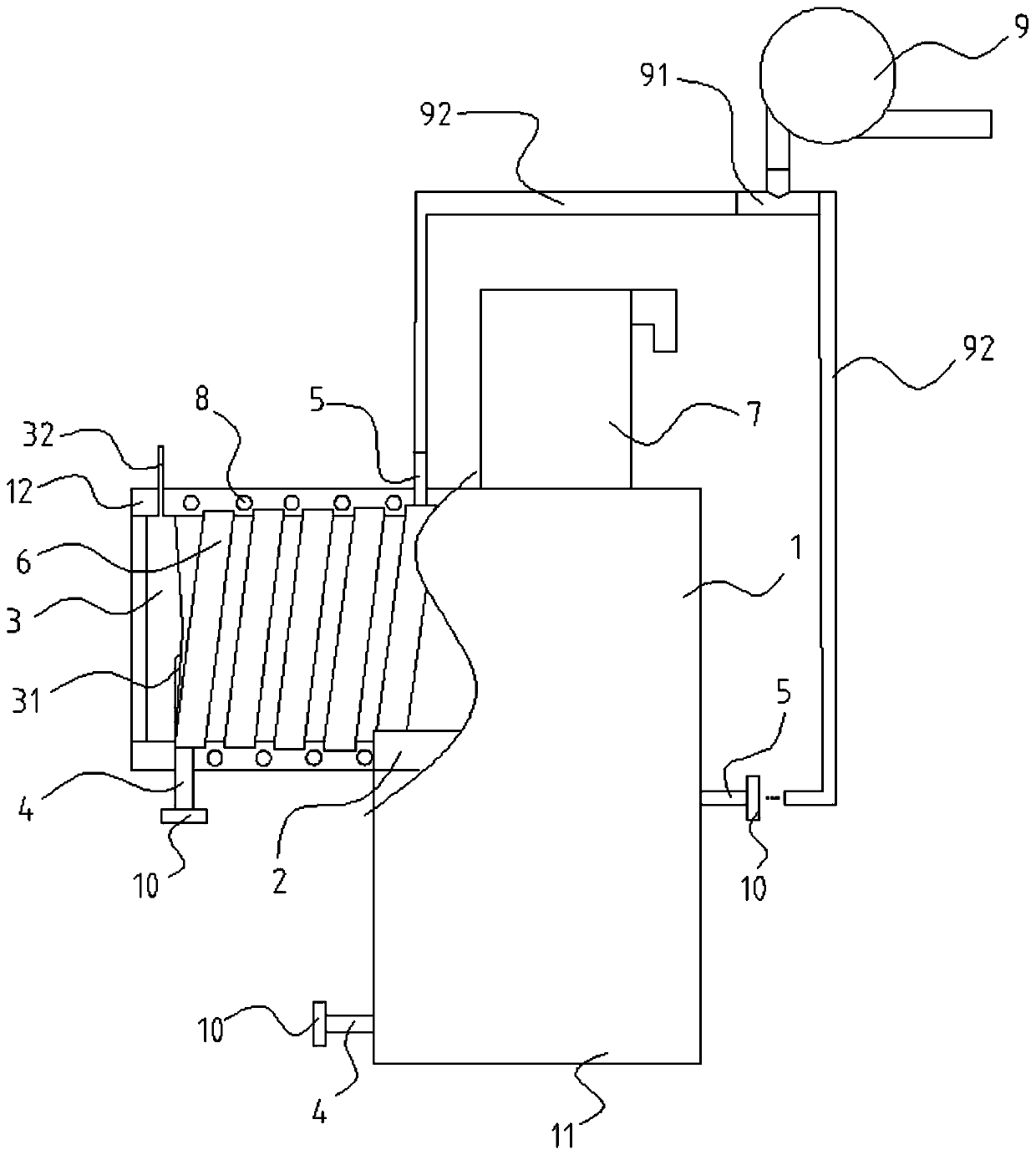

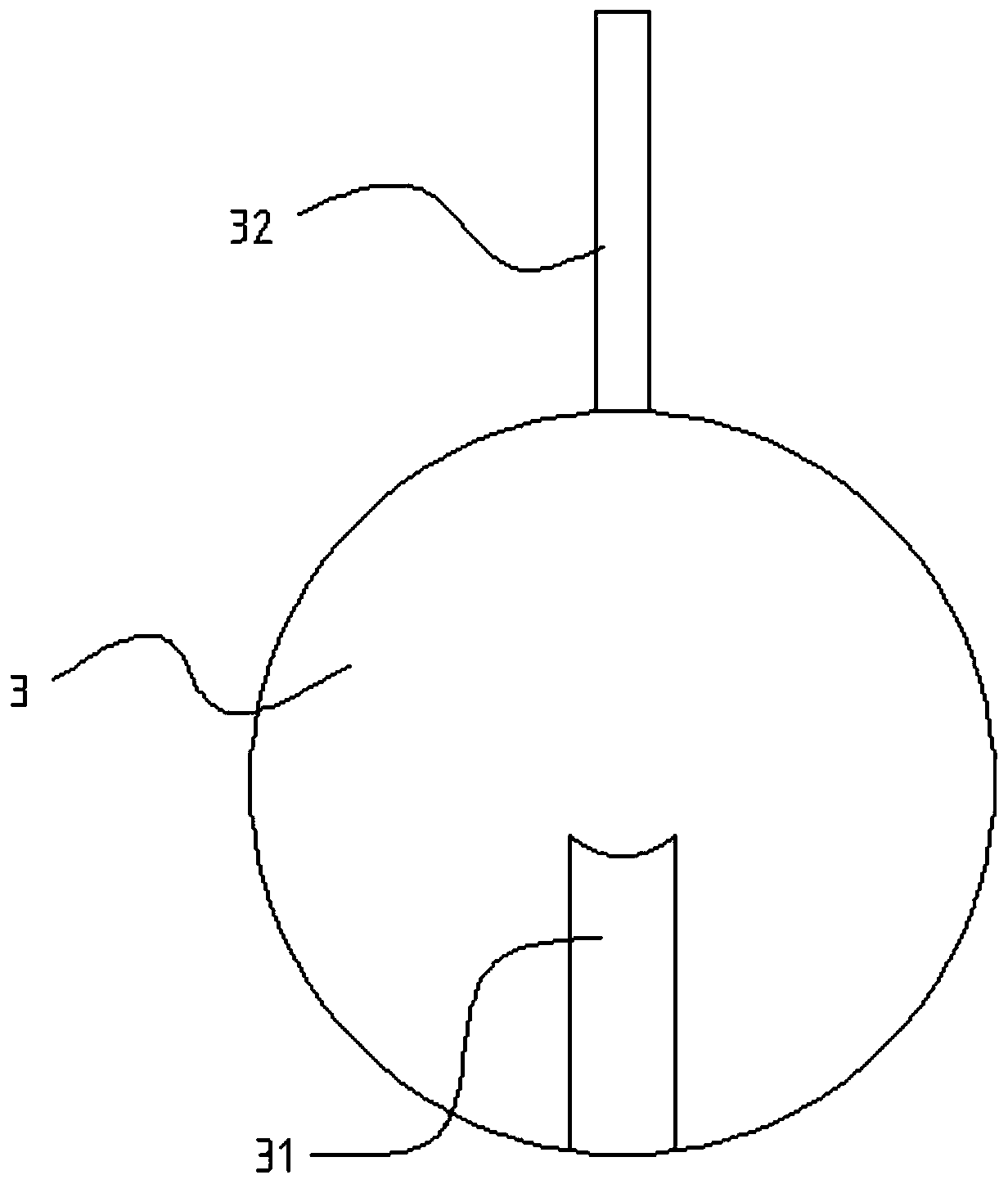

[0017] In order to make it easy to understand the technical means, creative features, goals and effects achieved by the present invention, the following examples are combined with the appended figure 1 to attach figure 2 The technical solutions provided by the present invention are described in detail, but the following content is not intended as a limitation of the present invention.

[0018] figure 1 It is a structural diagram of an embodiment of a pulse solenoid valve of the present invention; figure 2 It is a structural diagram of a control valve in a preferred embodiment of the present invention. Such as figure 1 and figure 2 As shown, the pulse solenoid valve provided in this embodiment includes: valve body 1, inlet 11, outlet 12, diaphragm 2, control valve 3, diversion port 31, valve stem 32, sewage outlet 4, liquid inlet hole 5, seal Cover 10 , diversion tank 6 , pulse structure 7 , heating coil 8 , liquid supply electric pump 9 , diverting tee 91 and conduit 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com