Automatic unloading mechanism, thread detection device and thread detection method

A technology of automatic unloading and detection device, applied in the direction of mechanical measuring device, measuring device, using mechanical device, etc., can solve the problems of high labor intensity of operators, affecting work efficiency, wasting manpower, etc., to reduce labor intensity of workers, improve Work efficiency and labor saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

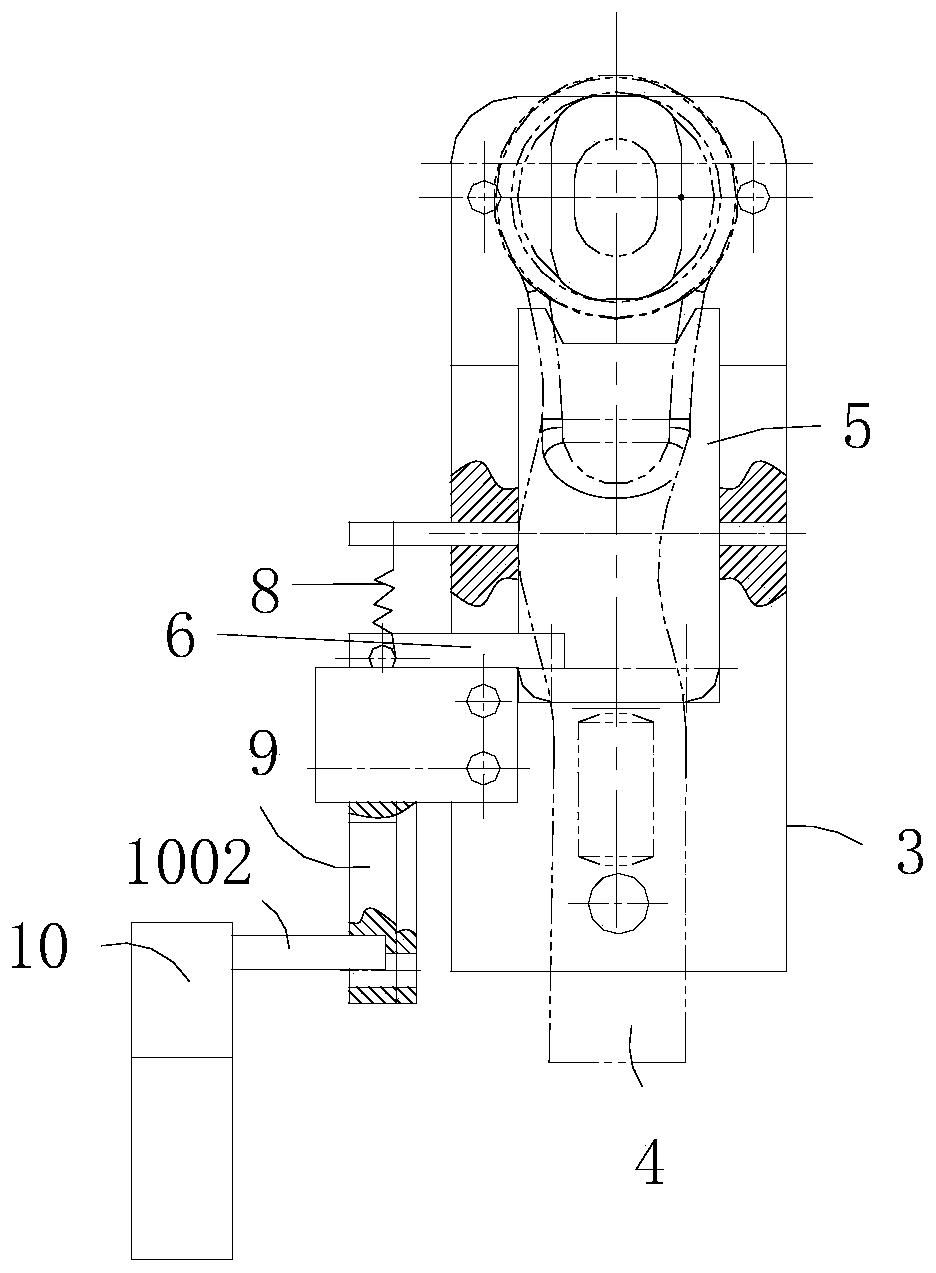

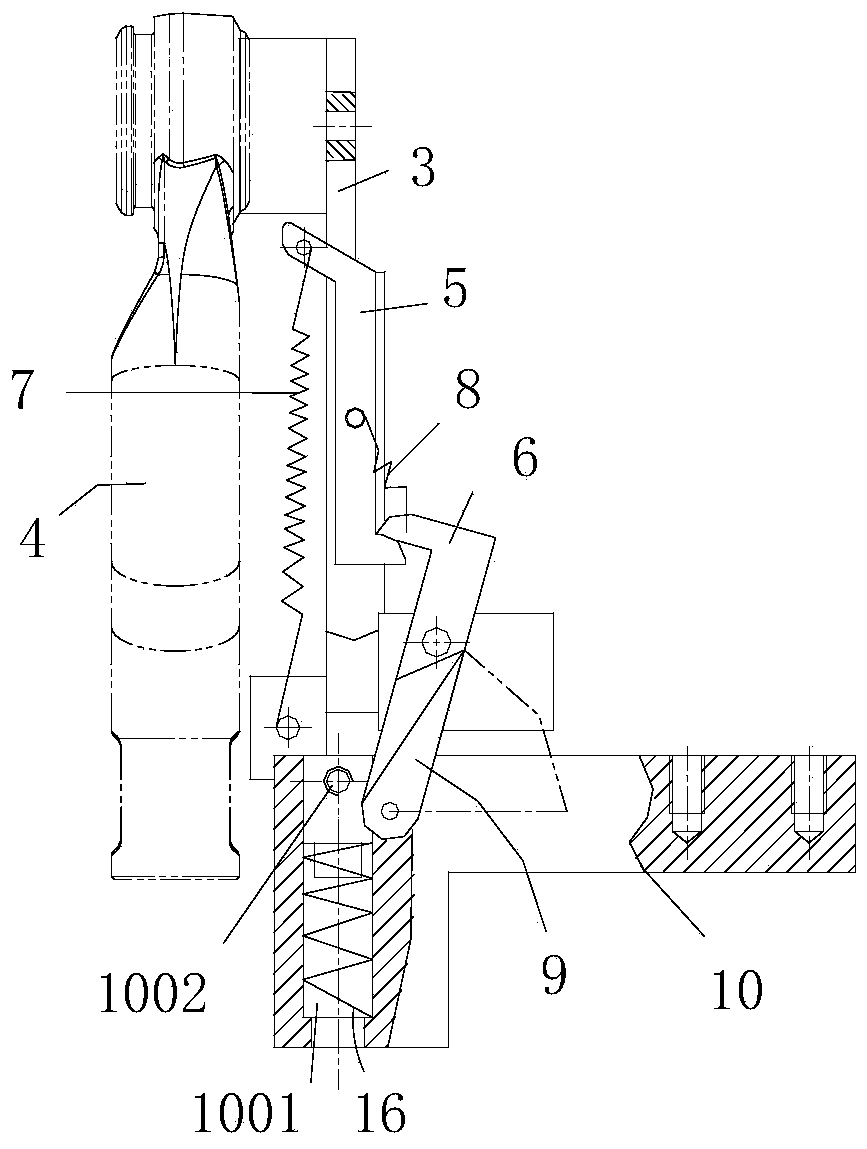

[0070] This embodiment relates to an automatic unloading mechanism, which is used to complete the automatic unloading process of workpieces, mainly including a mounting part 1, a first rotating drive device 2, a clamping part 3, a first rotating part 5, and a second rotating part 6. The third rotating member 9, the first elastic device 7, the second elastic device 8 and the blocking part 1002, wherein: the first rotating drive device 2 is fixed on the mounting part 1; the clamping part 3 is used to form the counterpart It is fixedly connected to the power output end of the first rotation drive device 2, and the workpiece can have forward rotation and reverse rotation relative to the installation part 1 because the clamping part 3 is under the control of the first rotation drive device 2. to turn.

[0071] The first rotating part 5 and the second rotating part 6 are respectively rotated on the fitting part 3, and one end of the first rotating part 5 is connected to the fitting ...

Embodiment 2

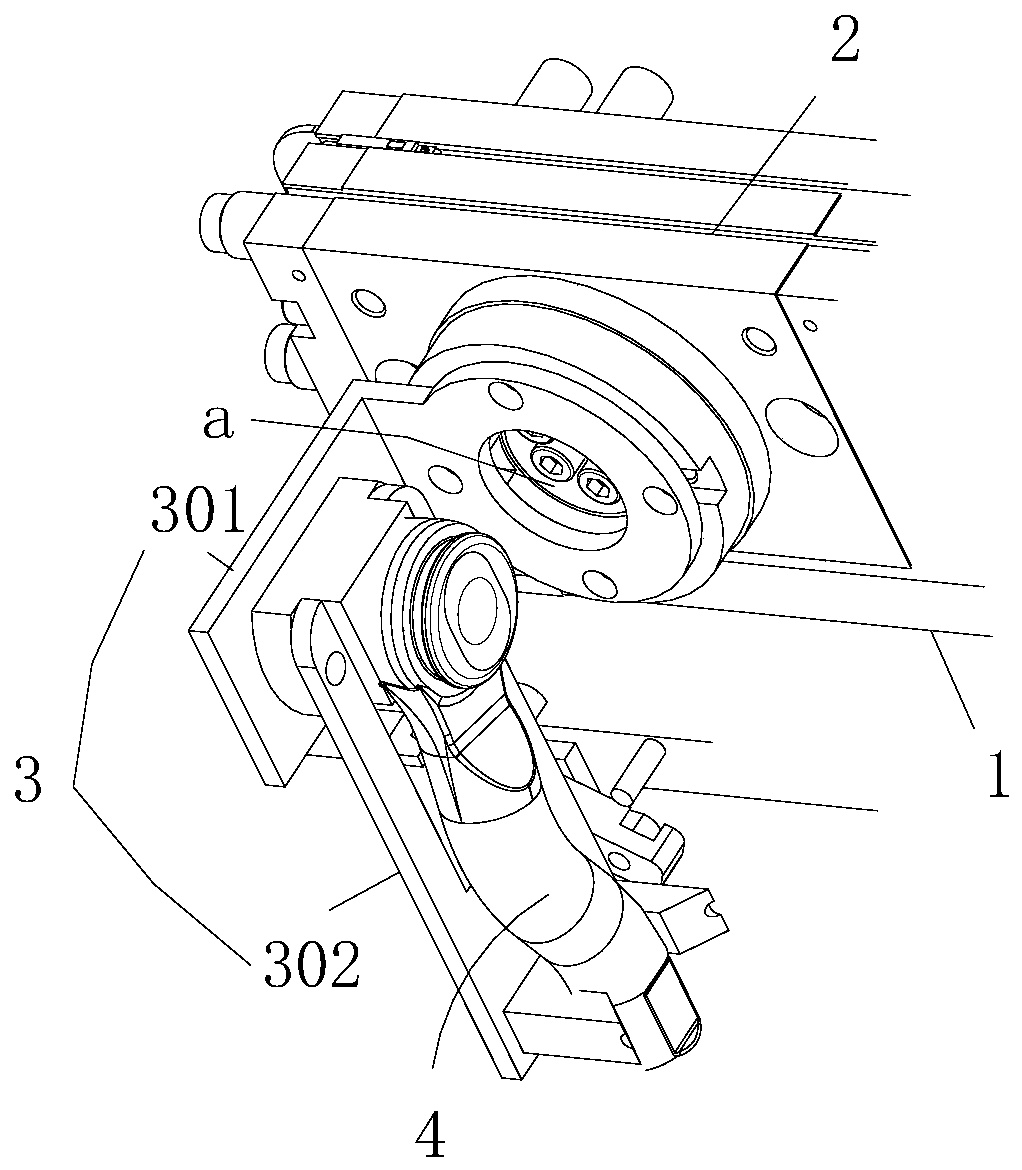

[0084] This embodiment relates to a thread detection device, such as Figure 7 to Figure 9 As shown, it includes the automatic unloading mechanism as in Embodiment 1, and also includes a fixed part and a processing part, wherein: the fixed part can be a frame or other structures, mainly providing an installation basis for other parts, and the automatic unloading mechanism in Embodiment 1 The installation part 1 is a slider that slides relative to the fixed part, and the processing part includes a second rotational drive device 11 fixedly disposed relative to the fixed part, and a threaded through gauge connected to the rotational power output end of the second rotational drive device 11. 18. Under the action of the first rotating drive device 2, the threaded part 4 can be rotated forward until the centerline of the threaded part coincides with the axial centerline of the threaded gauge 18.

[0085] The second rotating drive device 11 is a structure with a rotating power output...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com